Installation

Input Output Interface

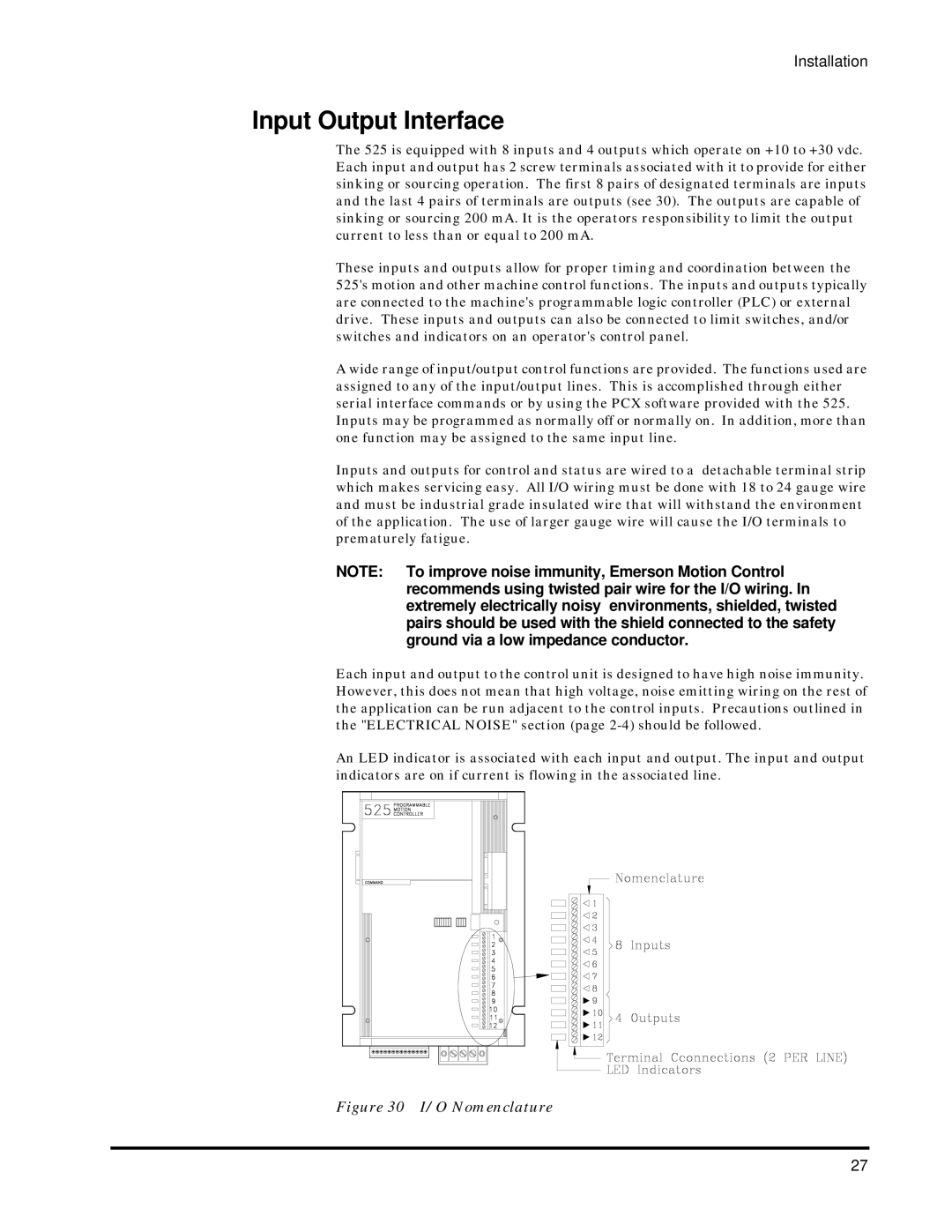

The 525 is equipped with 8 inputs and 4 outputs which operate on +10 to +30 vdc. Each input and output has 2 screw terminals associated with it to provide for either sinking or sourcing operation. The first 8 pairs of designated terminals are inputs and the last 4 pairs of terminals are outputs (see 30). The outputs are capable of sinking or sourcing 200 mA. It is the operators responsibility to limit the output current to less than or equal to 200 mA.

These inputs and outputs allow for proper timing and coordination between the 525's motion and other machine control functions. The inputs and outputs typically are connected to the machine's programmable logic controller (PLC) or external drive. These inputs and outputs can also be connected to limit switches, and/or switches and indicators on an operator's control panel.

A wide range of input/output control functions are provided. The functions used are assigned to any of the input/output lines. This is accomplished through either serial interface commands or by using the PCX software provided with the 525. Inputs may be programmed as normally off or normally on. In addition, more than one function may be assigned to the same input line.

Inputs and outputs for control and status are wired to a detachable terminal strip which makes servicing easy. All I/O wiring must be done with 18 to 24 gauge wire and must be industrial grade insulated wire that will withstand the environment of the application. The use of larger gauge wire will cause the I/O terminals to prematurely fatigue.

NOTE: To improve noise immunity, Emerson Motion Control recommends using twisted pair wire for the I/O wiring. In extremely electrically noisy environments, shielded, twisted pairs should be used with the shield connected to the safety ground via a low impedance conductor.

Each input and output to the control unit is designed to have high noise immunity. However, this does not mean that high voltage, noise emitting wiring on the rest of the application can be run adjacent to the control inputs. Precautions outlined in the "ELECTRICAL NOISE" section (page

An LED indicator is associated with each input and output. The input and output indicators are on if current is flowing in the associated line.

Figure 30 I/O Nomenclature

27