•Solidified shortening in the pan or filter lines, or

•Attempting to filter unheated oil or shortening (cold oil is more viscous, overloading the pump motor and causing it to overheat).

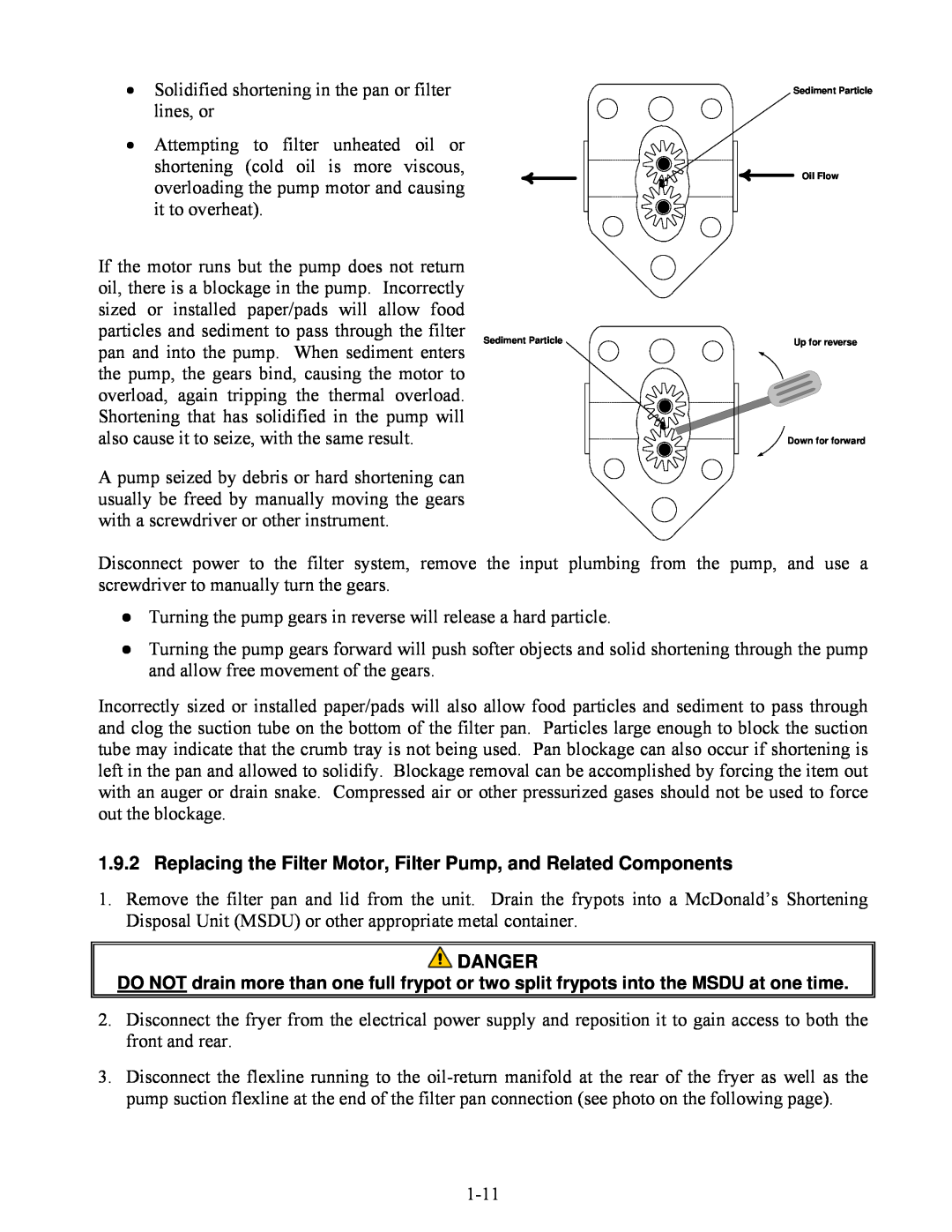

If the motor runs but the pump does not return oil, there is a blockage in the pump. Incorrectly sized or installed paper/pads will allow food particles and sediment to pass through the filter

pan and into the pump. When sediment enters Sediment Particle the pump, the gears bind, causing the motor to overload, again tripping the thermal overload.

Shortening that has solidified in the pump will also cause it to seize, with the same result.

A pump seized by debris or hard shortening can usually be freed by manually moving the gears with a screwdriver or other instrument.

Sediment Particle

Oil Flow

Up for reverse

![]() Down for forward

Down for forward

Disconnect power to the filter system, remove the input plumbing from the pump, and use a screwdriver to manually turn the gears.

●Turning the pump gears in reverse will release a hard particle.

●Turning the pump gears forward will push softer objects and solid shortening through the pump and allow free movement of the gears.

Incorrectly sized or installed paper/pads will also allow food particles and sediment to pass through and clog the suction tube on the bottom of the filter pan. Particles large enough to block the suction tube may indicate that the crumb tray is not being used. Pan blockage can also occur if shortening is left in the pan and allowed to solidify. Blockage removal can be accomplished by forcing the item out with an auger or drain snake. Compressed air or other pressurized gases should not be used to force out the blockage.

1.9.2 Replacing the Filter Motor, Filter Pump, and Related Components

1.Remove the filter pan and lid from the unit. Drain the frypots into a McDonald’s Shortening Disposal Unit (MSDU) or other appropriate metal container.

![]() DANGER

DANGER

DO NOT drain more than one full frypot or two split frypots into the MSDU at one time.

2.Disconnect the fryer from the electrical power supply and reposition it to gain access to both the front and rear.

3.Disconnect the flexline running to the