GEK±91584D, Vertical Drilling Motor, Type GE752

1.Remove all corrosion.

2.Wipe off the surface with clean rags and wet with petroleum spirits GE±D5B8.

3.Follow with a clean rag wet with methanol, then wipe dry. DO NOT touch the cleaned surface with bare hands.

4.Slush immediately after cleaning with GE±D6C6A1 slushing compound.

SKIDDING

curely support and enclose the armature in a totally en- closed wooden box of sufficient strength to protect the it from damage.

1.Clean the armature by removing dirt, oil or grease from its surface.

2.Treat all unpainted, exposed finished surfaces as follows:

a.Remove any corrosion.

b.Wipe off the surface with a clean cloth dipped in petroleum spirits, GE±D5B8.

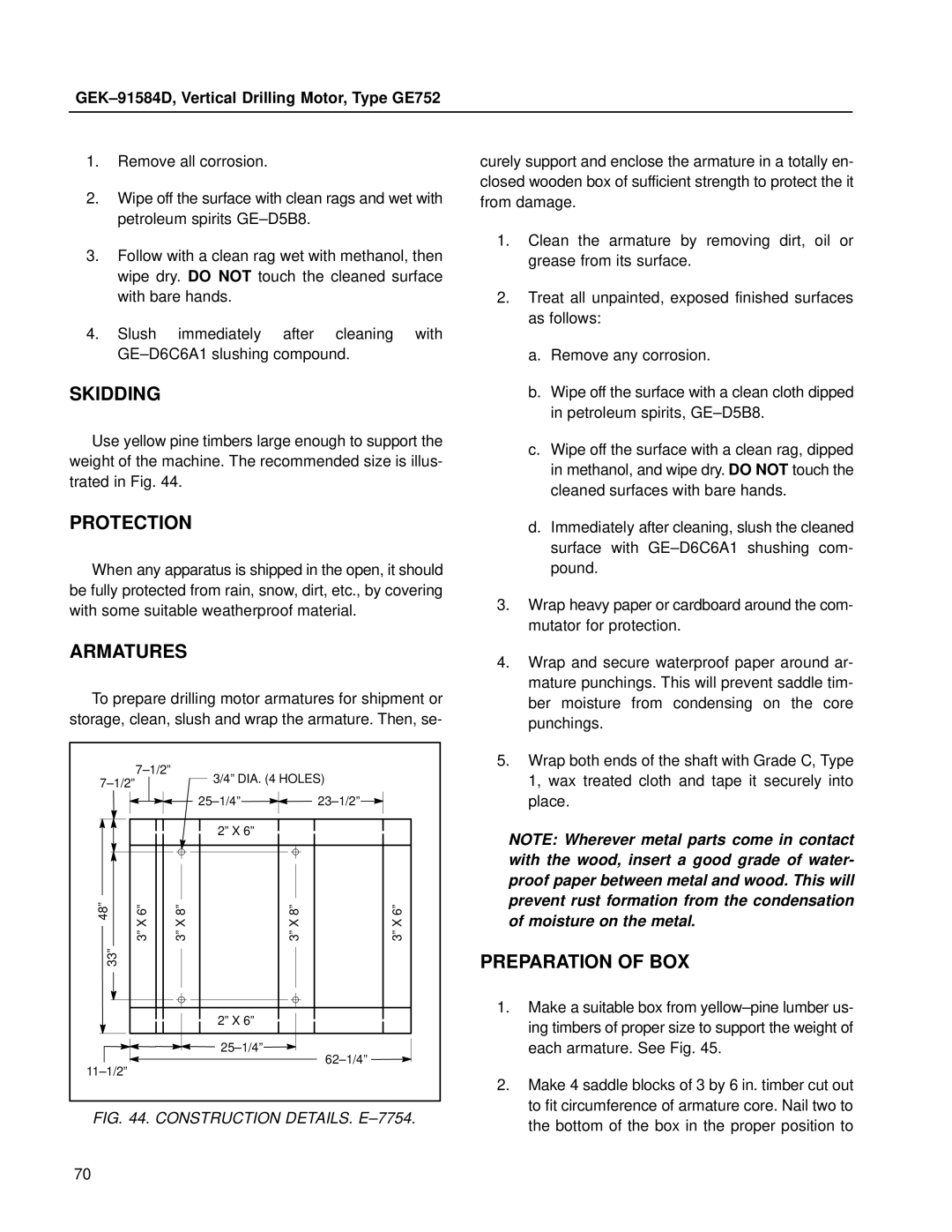

Use yellow pine timbers large enough to support the weight of the machine. The recommended size is illus- trated in Fig. 44.

PROTECTION

When any apparatus is shipped in the open, it should be fully protected from rain, snow, dirt, etc., by covering with some suitable weatherproof material.

ARMATURES

To prepare drilling motor armatures for shipment or storage, clean, slush and wrap the armature. Then, se-

7±1/2º | 7±1/2º | 3/4º DIA. (4 HOLES) |

| |

|

| |||

|

|

|

| |

|

| 25±1/4º | 23±1/2º |

|

|

| 2º X 6º |

|

|

48º | X 6º | X 8º | X 8º | X 6º |

| 3º | 3º | 3º | 3º |

33º |

|

|

|

|

|

| 2º X 6º |

|

|

|

| 25±1/4º | 62±1/4º |

|

11±1/2º |

|

|

| |

|

|

|

| |

FIG. 44. CONSTRUCTION DETAILS. E±7754.

c.Wipe off the surface with a clean rag, dipped in methanol, and wipe dry. DO NOT touch the cleaned surfaces with bare hands.

d.Immediately after cleaning, slush the cleaned surface with GE±D6C6A1 shushing com- pound.

3.Wrap heavy paper or cardboard around the com- mutator for protection.

4.Wrap and secure waterproof paper around ar- mature punchings. This will prevent saddle tim- ber moisture from condensing on the core punchings.

5.Wrap both ends of the shaft with Grade C, Type 1, wax treated cloth and tape it securely into place.

NOTE: Wherever metal parts come in contact with the wood, insert a good grade of water- proof paper between metal and wood. This will prevent rust formation from the condensation of moisture on the metal.

PREPARATION OF BOX

1.Make a suitable box from yellow±pine lumber us- ing timbers of proper size to support the weight of each armature. See Fig. 45.

2.Make 4 saddle blocks of 3 by 6 in. timber cut out to fit circumference of armature core. Nail two to the bottom of the box in the proper position to

70