|

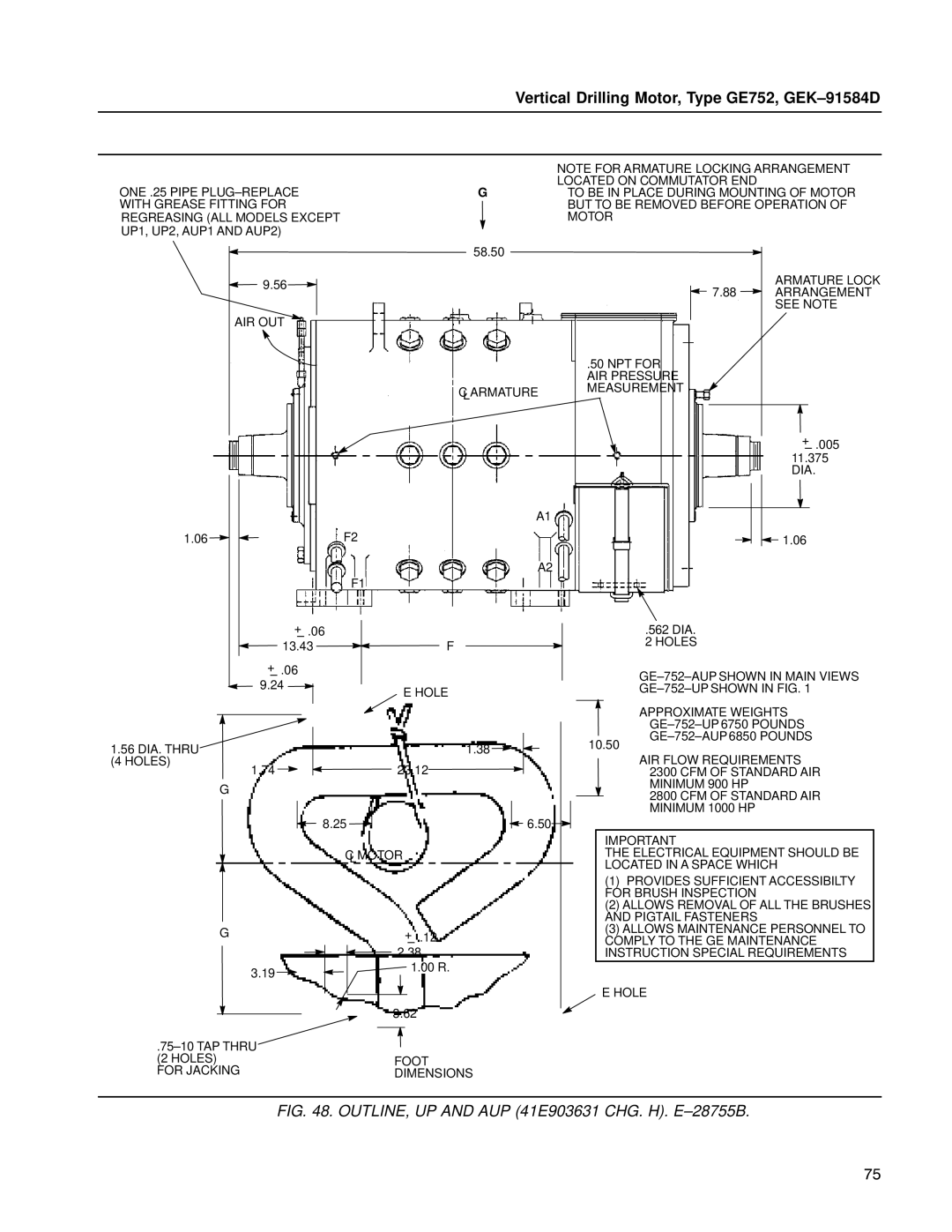

| Vertical Drilling Motor, Type GE752, GEK±91584D |

|

|

|

|

| NOTE FOR ARMATURE LOCKING ARRANGEMENT |

ONE .25 PIPE PLUG±REPLACE | G | LOCATED ON COMMUTATOR END |

TO BE IN PLACE DURING MOUNTING OF MOTOR | ||

WITH GREASE FITTING FOR |

| BUT TO BE REMOVED BEFORE OPERATION OF |

REGREASING (ALL MODELS EXCEPT |

| MOTOR |

UP1, UP2, AUP1 AND AUP2) |

|

|

| 58.50 |

|

9.56

AIR OUT

C ARMATURE

L

ARMATURE LOCK

7.88 ![]() ARRANGEMENT SEE NOTE

ARRANGEMENT SEE NOTE

.50 NPT FOR AIR PRESSURE MEASUREMENT

A1

1.06![]() F2

F2

A2

|

| F1 |

+ | .06 |

|

± | F | |

13.43 | ||

+± .06 9.24

E HOLE

1.56 DIA. THRU | 1.38 |

(4 HOLES) | 23.12 |

1.74 | |

G |

|

8.25 | 6.50 |

10.50

+± .005 11.375 DIA.

1.06

.562 DIA.

2 HOLES

GE±752±AUP SHOWN IN MAIN VIEWS GE±752±UP SHOWN IN FIG. 1

APPROXIMATE WEIGHTS GE±752±UP 6750 POUNDS GE±752±AUP 6850 POUNDS

AIR FLOW REQUIREMENTS 2300 CFM OF STANDARD AIR MINIMUM 900 HP

2800 CFM OF STANDARD AIR MINIMUM 1000 HP

C MOTOR

L

G | + |

| ± .12 |

| 2.38 |

3.19 | 1.00 R. |

| |

| 3.62 |

.75±10 TAP THRU |

|

(2 HOLES) | FOOT |

FOR JACKING | DIMENSIONS |

IMPORTANT

THE ELECTRICAL EQUIPMENT SHOULD BE LOCATED IN A SPACE WHICH

(1)PROVIDES SUFFICIENT ACCESSIBILTY FOR BRUSH INSPECTION

(2)ALLOWS REMOVAL OF ALL THE BRUSHES AND PIGTAIL FASTENERS

(3)ALLOWS MAINTENANCE PERSONNEL TO COMPLY TO THE GE MAINTENANCE INSTRUCTION SPECIAL REQUIREMENTS

E HOLE

FIG. 48. OUTLINE, UP AND AUP (41E903631 CHG. H). E±28755B.

75