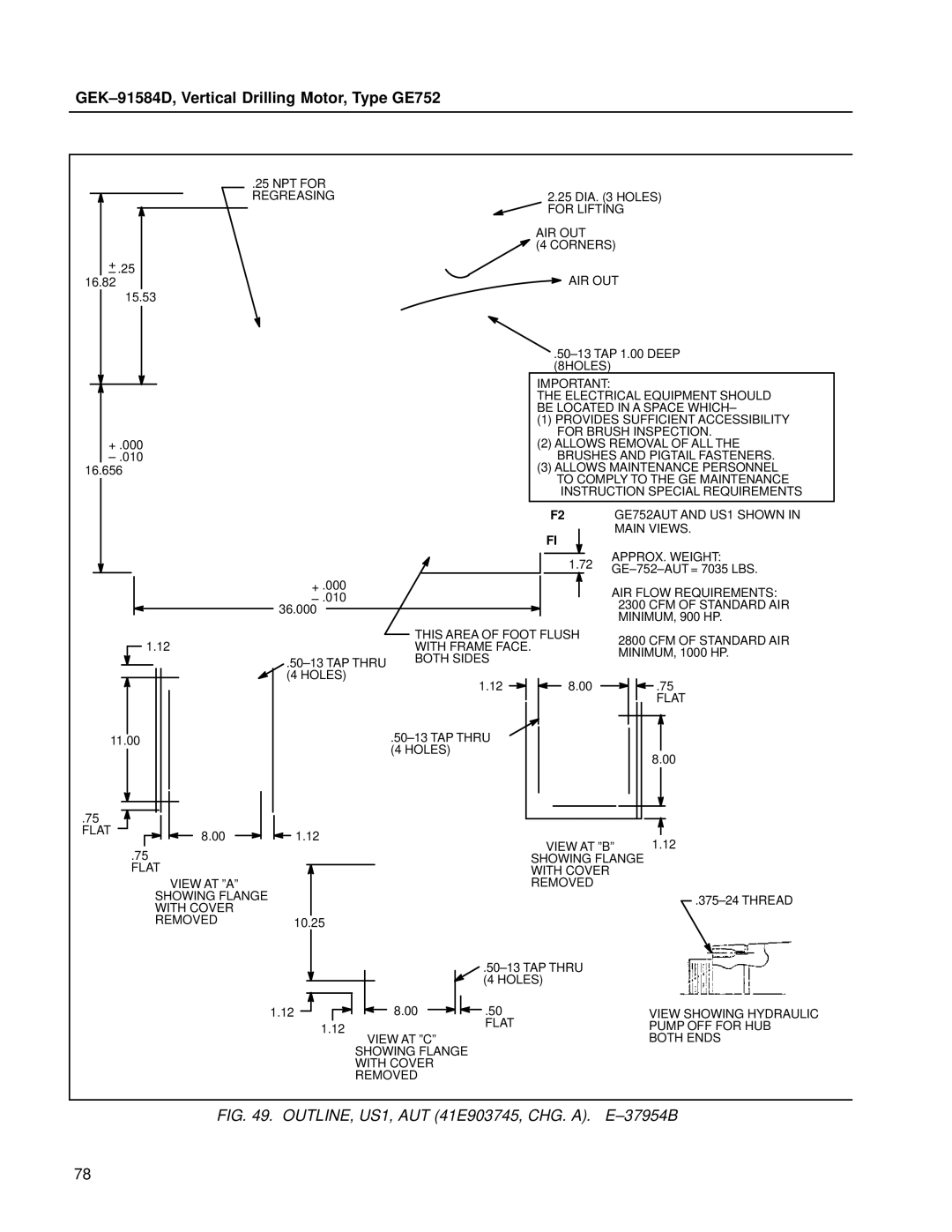

GEK±91584D, Vertical Drilling Motor, Type GE752

.25 NPT FOR REGREASING

+± .25

16.82

15.53

+.000

± .010

16.656

2.25DIA. (3 HOLES) FOR LIFTING

AIR OUT

![]() (4 CORNERS)

(4 CORNERS)

AIR OUT

.50±13 TAP 1.00 DEEP (8HOLES)

IMPORTANT:

THE ELECTRICAL EQUIPMENT SHOULD BE LOCATED IN A SPACE WHICH±

(1)PROVIDES SUFFICIENT ACCESSIBILITY FOR BRUSH INSPECTION.

(2)ALLOWS REMOVAL OF ALL THE BRUSHES AND PIGTAIL FASTENERS.

(3)ALLOWS MAINTENANCE PERSONNEL TO COMPLY TO THE GE MAINTENANCE INSTRUCTION SPECIAL REQUIREMENTS

+ .000

± .010

36.000

1.12

.50±13 TAP THRU (4 HOLES)

11.00

.75 |

|

|

FLAT | 8.00 | 1.12 |

|

.75 FLAT

VIEW AT ºAº

SHOWING FLANGE

WITH COVER

REMOVED10.25

F2 | GE752AUT AND US1 SHOWN IN | |

FI | MAIN VIEWS. | |

| ||

1.72 | APPROX. WEIGHT: | |

GE±752±AUT = 7035 LBS. | ||

| ||

| AIR FLOW REQUIREMENTS: | |

| 2300 CFM OF STANDARD AIR | |

| MINIMUM, 900 HP. | |

THIS AREA OF FOOT FLUSH | 2800 CFM OF STANDARD AIR | |

WITH FRAME FACE. | ||

MINIMUM, 1000 HP. | ||

BOTH SIDES | ||

|

1.12![]()

![]() 8.00

8.00 ![]() .75 FLAT

.75 FLAT

.50±13 TAP THRU (4 HOLES)

8.00

VIEW AT ºBº | 1.12 |

SHOWING FLANGE

WITH COVER

REMOVED

.375±24 THREAD

.50±13 TAP THRU (4 HOLES)

1.12 | 8.00 | .50 |

| 1.12 | FLAT |

|

|

VIEW AT ºCº

SHOWING FLANGE

WITH COVER

REMOVED

VIEW SHOWING HYDRAULIC PUMP OFF FOR HUB BOTH ENDS

FIG. 49. OUTLINE, US1, AUT (41E903745, CHG. A). E±37954B

78