GEK±91584D, Vertical Drilling Motor, Type GE752

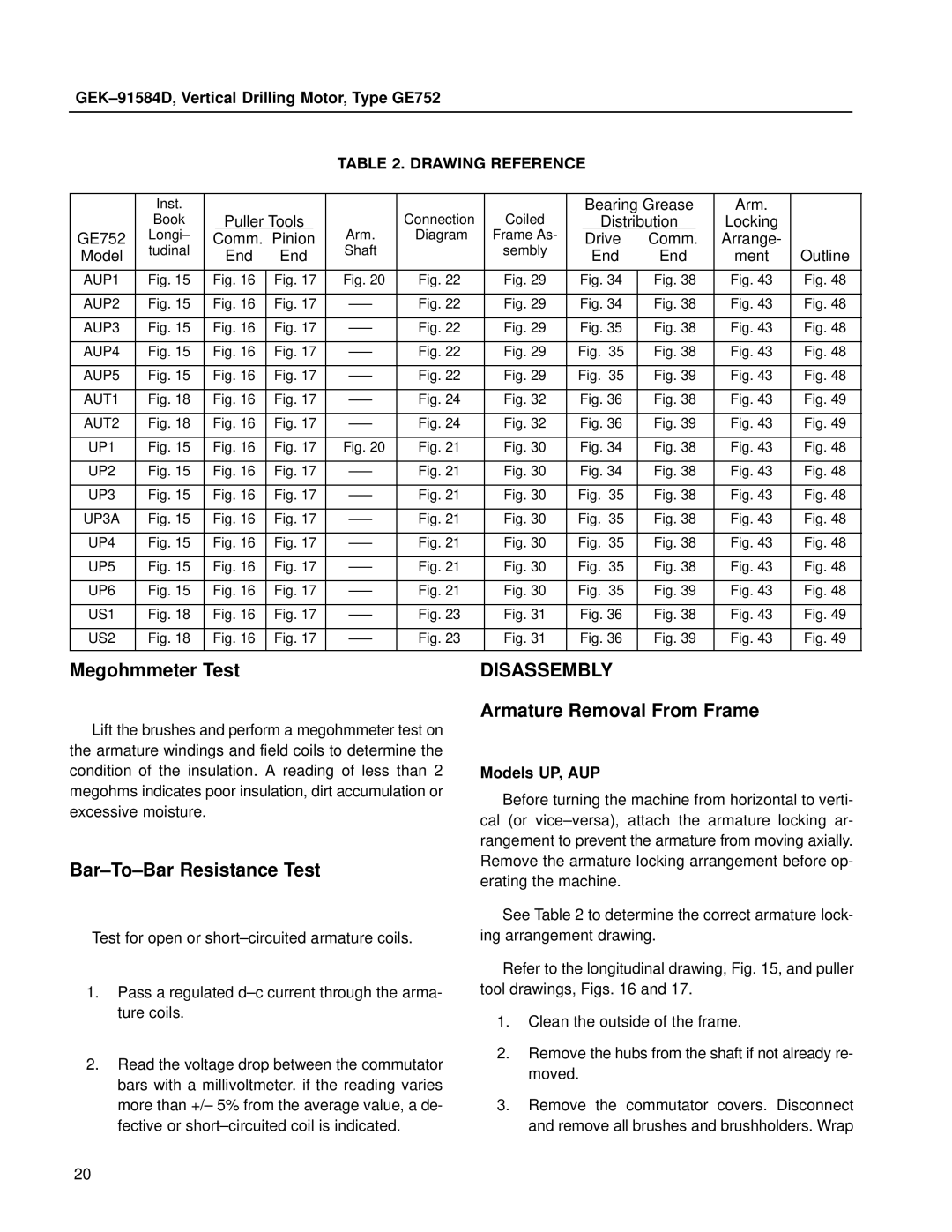

TABLE 2. DRAWING REFERENCE

| Inst. |

|

|

|

|

|

| Bearing Grease | Arm. |

| |||

| Book | Puller Tools |

| Connection | Coiled |

| Distribution |

| Locking |

| |||

GE752 | Longi± | Comm. Pinion | Arm. | Diagram | Frame As- |

| Drive | Comm. | Arrange- |

| |||

Model | tudinal | End | End | Shaft |

| sembly |

| End | End | ment | Outline | ||

|

|

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

| |||

AUP1 | Fig. 15 | Fig. 16 | Fig. 17 | Fig. 20 | Fig. 22 | Fig. 29 | Fig. 34 | Fig. 38 | Fig. 43 | Fig. 48 | |||

|

|

|

|

|

|

|

|

|

|

| |||

AUP2 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 22 | Fig. 29 | Fig. 34 | Fig. 38 | Fig. 43 | Fig. 48 | |||

|

|

|

|

|

|

|

|

|

|

| |||

AUP3 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 22 | Fig. 29 | Fig. 35 | Fig. 38 | Fig. 43 | Fig. 48 | |||

|

|

|

|

|

|

|

|

|

|

|

| ||

AUP4 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 22 | Fig. 29 | Fig. | 35 | Fig. 38 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

|

| ||

AUP5 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 22 | Fig. 29 | Fig. | 35 | Fig. 39 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

| |||

AUT1 | Fig. 18 | Fig. 16 | Fig. 17 | ±±± | Fig. 24 | Fig. 32 | Fig. 36 | Fig. 38 | Fig. 43 | Fig. 49 | |||

|

|

|

|

|

|

|

|

|

|

| |||

AUT2 | Fig. 18 | Fig. 16 | Fig. 17 | ±±± | Fig. 24 | Fig. 32 | Fig. 36 | Fig. 39 | Fig. 43 | Fig. 49 | |||

|

|

|

|

|

|

|

|

|

|

| |||

UP1 | Fig. 15 | Fig. 16 | Fig. 17 | Fig. 20 | Fig. 21 | Fig. 30 | Fig. 34 | Fig. 38 | Fig. 43 | Fig. 48 | |||

|

|

|

|

|

|

|

|

|

|

| |||

UP2 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 21 | Fig. 30 | Fig. 34 | Fig. 38 | Fig. 43 | Fig. 48 | |||

|

|

|

|

|

|

|

|

|

|

|

| ||

UP3 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 21 | Fig. 30 | Fig. | 35 | Fig. 38 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

|

| ||

UP3A | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 21 | Fig. 30 | Fig. | 35 | Fig. 38 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

|

| ||

UP4 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 21 | Fig. 30 | Fig. | 35 | Fig. 38 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

|

| ||

UP5 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 21 | Fig. 30 | Fig. | 35 | Fig. 38 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

|

| ||

UP6 | Fig. 15 | Fig. 16 | Fig. 17 | ±±± | Fig. 21 | Fig. 30 | Fig. | 35 | Fig. 39 | Fig. 43 | Fig. 48 | ||

|

|

|

|

|

|

|

|

|

|

| |||

US1 | Fig. 18 | Fig. 16 | Fig. 17 | ±±± | Fig. 23 | Fig. 31 | Fig. 36 | Fig. 38 | Fig. 43 | Fig. 49 | |||

|

|

|

|

|

|

|

|

|

|

| |||

US2 | Fig. 18 | Fig. 16 | Fig. 17 | ±±± | Fig. 23 | Fig. 31 | Fig. 36 | Fig. 39 | Fig. 43 | Fig. 49 | |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Megohmmeter Test

Lift the brushes and perform a megohmmeter test on the armature windings and field coils to determine the condition of the insulation. A reading of less than 2 megohms indicates poor insulation, dirt accumulation or excessive moisture.

Bar±To±Bar Resistance Test

Test for open or short±circuited armature coils.

1.Pass a regulated d±c current through the arma- ture coils.

2.Read the voltage drop between the commutator bars with a millivoltmeter. if the reading varies more than +/± 5% from the average value, a de- fective or short±circuited coil is indicated.

DISASSEMBLY

Armature Removal From Frame

Models UP, AUP

Before turning the machine from horizontal to verti- cal (or vice±versa), attach the armature locking ar- rangement to prevent the armature from moving axially. Remove the armature locking arrangement before op- erating the machine.

See Table 2 to determine the correct armature lock- ing arrangement drawing.

Refer to the longitudinal drawing, Fig. 15, and puller tool drawings, Figs. 16 and 17.

1.Clean the outside of the frame.

2.Remove the hubs from the shaft if not already re- moved.

3.Remove the commutator covers. Disconnect and remove all brushes and brushholders. Wrap

20