Vertical Drilling Motor, Type GE752, GEK±91584D

FIG. 7. DIAGRAM OF CONNECTIONS TO RUN A SERIES MACHINE FROM A WELDING SET.

E±28718.

leads so machine will operate as a series motor, and the armature will rotate counterclockwise (viewed from the commutator end).

Preparation For Operating Shunt Model Machines For Commutator Resurfacing

1.Break the coupling (if applicable) so the machine can be run from a d±c power source.

2.Lift all brushes except two of opposite polarity (adjacent brushholders) which are necessary to operate the motor.

3.Connect the machine to an outside source of controlled d±c power, Fig. 8.

4.Apply power as follows:

a.Increase the field supply (0±50 v) to 32.0 volts at 25 amps.

b.Increase the armature supply (0±150 v) to 150 volts.

c.Slowly decrease the field supply to bring the speed up to 1000 rpm.

FIG. 8. CONNECTIONS TO RUN A SHUNT MACHINE FROM A D±C POWER SOURCE.

E±23930A.

NOTE: When shutting down, increase the field supply to maximum, and then turn off the arma- ture supply. After the armature supply has been shut off, shut down the field supply.

Sanding Procedure

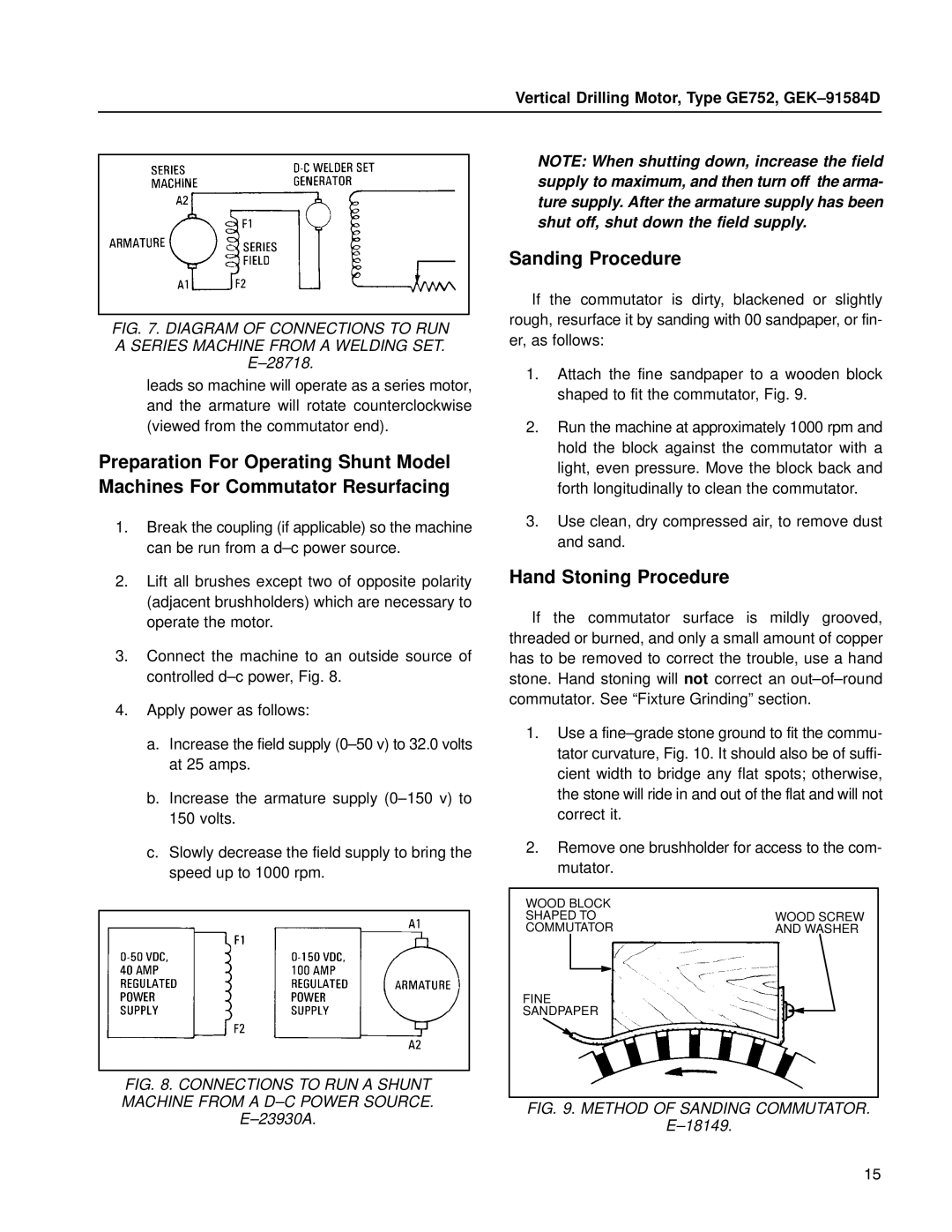

If the commutator is dirty, blackened or slightly rough, resurface it by sanding with 00 sandpaper, or fin- er, as follows:

1.Attach the fine sandpaper to a wooden block shaped to fit the commutator, Fig. 9.

2.Run the machine at approximately 1000 rpm and hold the block against the commutator with a light, even pressure. Move the block back and forth longitudinally to clean the commutator.

3.Use clean, dry compressed air, to remove dust and sand.

Hand Stoning Procedure

If the commutator surface is mildly grooved, threaded or burned, and only a small amount of copper has to be removed to correct the trouble, use a hand stone. Hand stoning will not correct an out±of±round commutator. See ªFixture Grindingº section.

1.Use a fine±grade stone ground to fit the commu- tator curvature, Fig. 10. It should also be of suffi- cient width to bridge any flat spots; otherwise, the stone will ride in and out of the flat and will not correct it.

2.Remove one brushholder for access to the com- mutator.

WOOD BLOCK |

| ||

SHAPED TO | WOOD SCREW | ||

COMMUTATOR | AND WASHER | ||

|

|

|

|

FINE |

| ||

SANDPAPER |

| ||

FIG. 9. METHOD OF SANDING COMMUTATOR.

E±18149.

15