GEK±91584D, Vertical Drilling Motor, Type GE752

SPECIAL TOOLS

AND EQUIPMENT

CAUTION: This machine is of open splash±proof construction. It is force±ventilated and requires an ample supply of cooling air. The cooling air should not contain combustible gases. If it is applied in an environment which may contain combustible gases, an adequate supply of non± contaminated cooling air must be provided.

The following items are required to maintain, repair and overhaul the motors:

Part

Megohmmeter (or ªMeggerº*)

600 volts . . . . . . . . . . . . . . . . 111X910 or equivalent

Voltmeter . . . . . . . . . . Simpson Multimeter, Model 260 or equivalent

Puller Tools . . . . . . . . . . . . . . . . . . . . . . . 41E903423G1

Commutator Grinder . . . . . . . . . . . . . . . . . 427C592G1

Resurfacing Stones:

Medium Grade . . . . . . . . . . . . . . . . . . . 8828492P11

Finish Grade . . . . . . . . . . . . . . . . . . . . . . 8828492P8

Brush±Seater Stone (White) . . . . . . . . . . . 106X98

Lifting Eye . . . . . . . . . . . . . . . . . . . . . . . . . . P9945894P8

Crows±Foot Pressing Tool . . . . . . . . . . 41C685430G1

Ball and Socket Tool . . . . . . . . . . . . . . . 41C685080G1

Guide Pins, Three (3) Recommended

for Armature Asm. In Frame . . . . . . . . 6717114P1

Spanner Wrench . . . . . . . . . . . . . . . . . . . . . 8843522G1

Spring Scale (for brush±spring

pressure check) . . . . . . . . . . . . . . 0±20 lb. capacity

Hub Assembly Gauge . . . . . . . . . . . . . . 41D790941G1

Hub Puller (Less Pump) . . . . . . . . . . . . 41B535703G1

Pump (For Above) . . . . . . . . . . . . . . . . . . . . 8843947G1

GROUNDING INSTRUCTIONS

Grounding motor frames is required to safeguard personnel from electric shock in event of an insulation failure in the machine.

WARNING: Failure to properly ground electrical equipment may expose personnel to a potentially hazardous condition in which serious or fatal in- jury from electrical shock is possible.

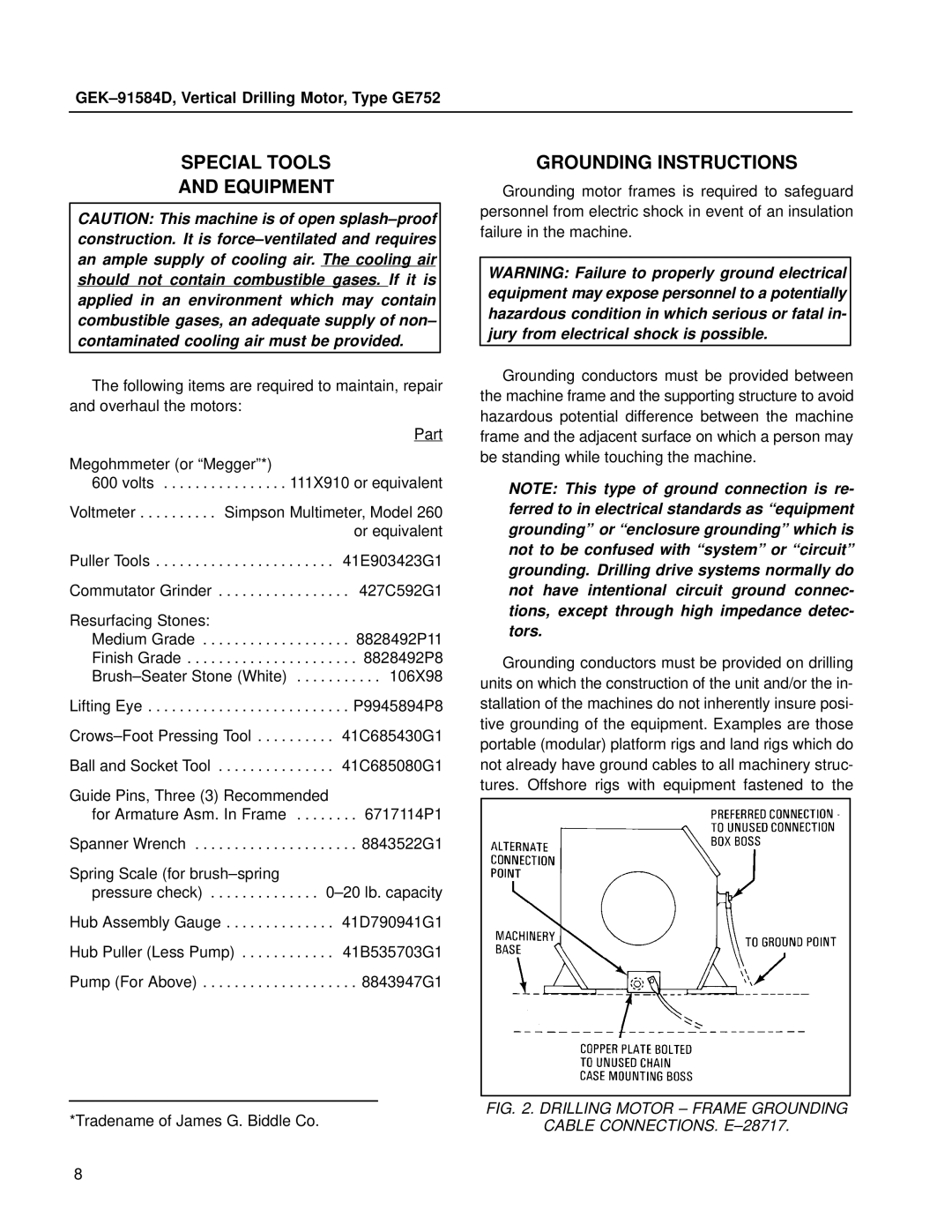

Grounding conductors must be provided between the machine frame and the supporting structure to avoid hazardous potential difference between the machine frame and the adjacent surface on which a person may be standing while touching the machine.

NOTE: This type of ground connection is re- ferred to in electrical standards as ªequipment groundingº or ªenclosure groundingº which is not to be confused with ªsystemº or ªcircuitº grounding. Drilling drive systems normally do not have intentional circuit ground connec- tions, except through high impedance detec- tors.

Grounding conductors must be provided on drilling units on which the construction of the unit and/or the in- stallation of the machines do not inherently insure posi- tive grounding of the equipment. Examples are those portable (modular) platform rigs and land rigs which do not already have ground cables to all machinery struc- tures. Offshore rigs with equipment fastened to the

*Tradename of James G. Biddle Co. | FIG. 2. DRILLING MOTOR ± FRAME GROUNDING | |

CABLE CONNECTIONS. E±28717. | ||

|

8