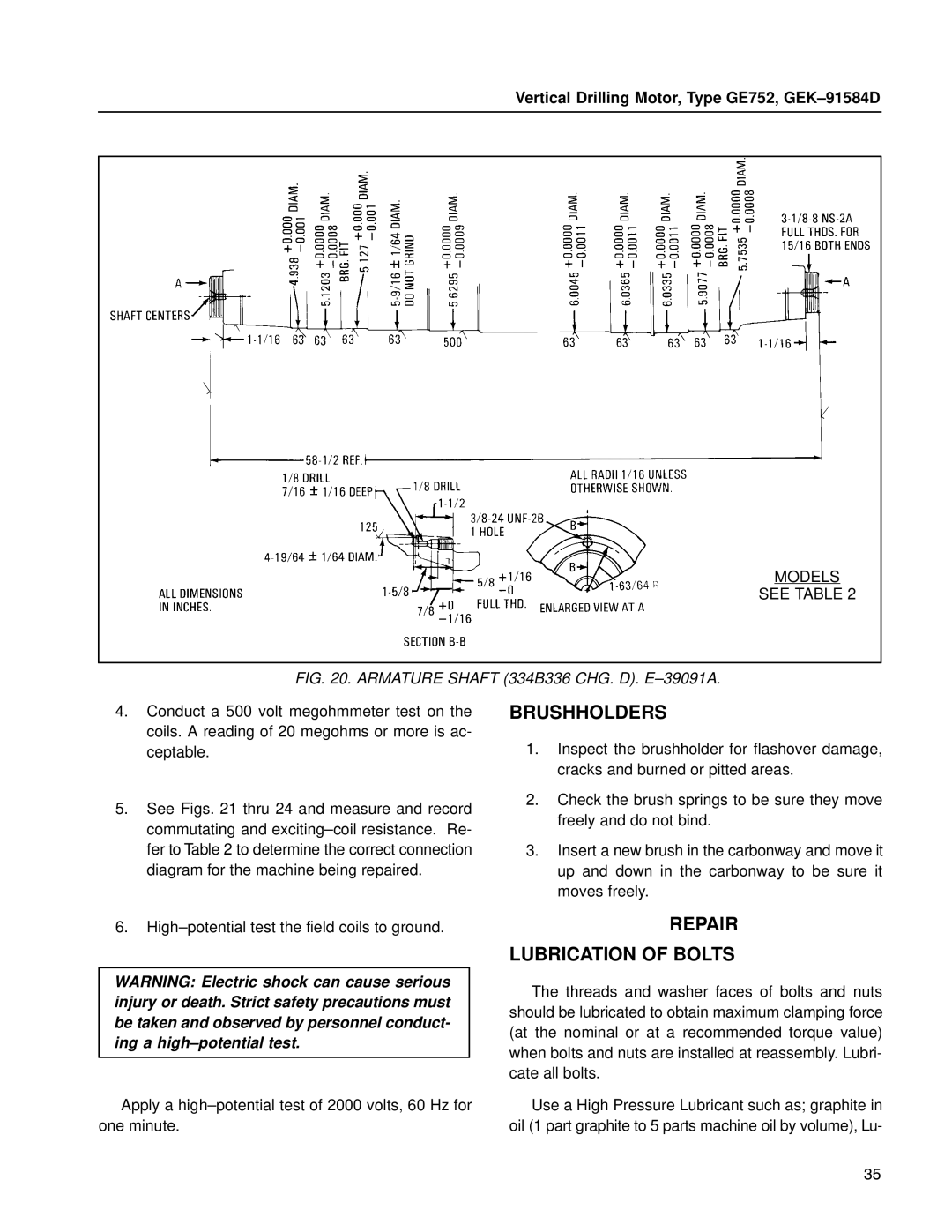

Vertical Drilling Motor, Type GE752, GEK±91584D

MODELS

SEE TABLE 2

FIG. 20. ARMATURE SHAFT (334B336 CHG. D). E±39091A.

4.Conduct a 500 volt megohmmeter test on the coils. A reading of 20 megohms or more is ac- ceptable.

5.See Figs. 21 thru 24 and measure and record commutating and exciting±coil resistance. Re- fer to Table 2 to determine the correct connection diagram for the machine being repaired.

6.High±potential test the field coils to ground.

WARNING: Electric shock can cause serious injury or death. Strict safety precautions must be taken and observed by personnel conduct- ing a high±potential test.

Apply a high±potential test of 2000 volts, 60 Hz for one minute.

BRUSHHOLDERS

1.Inspect the brushholder for flashover damage, cracks and burned or pitted areas.

2.Check the brush springs to be sure they move freely and do not bind.

3.Insert a new brush in the carbonway and move it up and down in the carbonway to be sure it moves freely.

REPAIR

LUBRICATION OF BOLTS

The threads and washer faces of bolts and nuts should be lubricated to obtain maximum clamping force (at the nominal or at a recommended torque value) when bolts and nuts are installed at reassembly. Lubri- cate all bolts.

Use a High Pressure Lubricant such as; graphite in oil (1 part graphite to 5 parts machine oil by volume), Lu-

35