Vertical Drilling Motor, Type GE752, GEK±91584D

FIG. 25. COMMUTATOR TIGHTENING.

E±4270B.

WARNING: During resurfacing operations, eye protection and a respirator should be worn to protect personnel from dust and fly- ing particles.

use slot guides and depth gauges for accurate, uniform cuts. Make a few practice passes over a scrap commu- tator to get the ªfeelº of the tool. Care must be taken to prevent the power undercutter from jumping out of the slot and across the commutator surface. The high± speed operation of the blade will quickly gouge the com- mutator.

1.After a commutator has been resurfaced, the mica between the bars should be undercut to a depth of 0.047 in. Undercutting should be done with a sharp±edged tool with a cutting width of 0.063 in.

2.Blow loose material off the commutator with dry, compressed air.

FIG. 26. COMMUTATOR PRESSING

DIAMETER. E±18140

WARNING: When using compressed air for cleaning purposes, flying debris and particles may present a hazard to personnel in the im- mediate area. Personnel should be provided with, and trained in the use of, personal pro- tective equipment as specified by applicable federal or state safety regulations.

Raking

Resurfacing usually leaves particles and slivers of copper hanging on the bar edges or lodged in the under- cut slots. These must be removed before the motor is placed in service, or the particles may bridge the side mica and cause a flashover.

1.Brush out dirt and copper whiskers attached to the trailing edge of the bars with a stiff±bristle brush; preferably one with nylon bristles. A new paint brush or stencil brush with the bristles cut short for added stiffness may also be satisfacto- ry. If stoning and undercutting have produced considerable dragging of copper from the edges of the bars, use a raking tool to remove the cop- per fins and ragged edges. Use the tool to rake the bar edges with the point inserted in the slot so that sides of the V rake the trailing edge of the bar. If the tool is ground with flat sides and used with moderate pressure as a raking tool, it will re- move ragged copper fins and break the sharp

12 | 1 |

5 | |

8 | 9 |

4 | 3 |

10 | 7 |

611

2

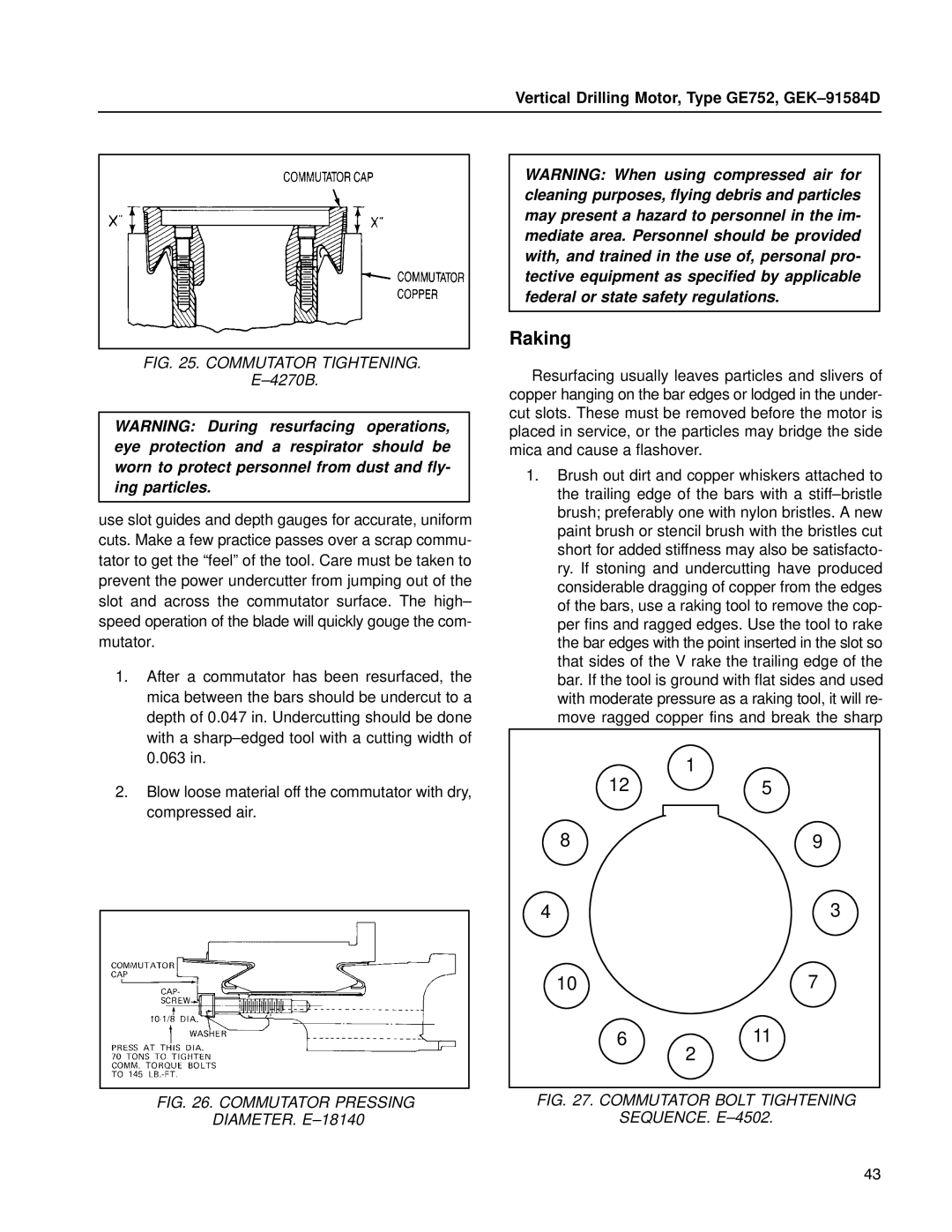

FIG. 27. COMMUTATOR BOLT TIGHTENING

SEQUENCE. E±4502.

43