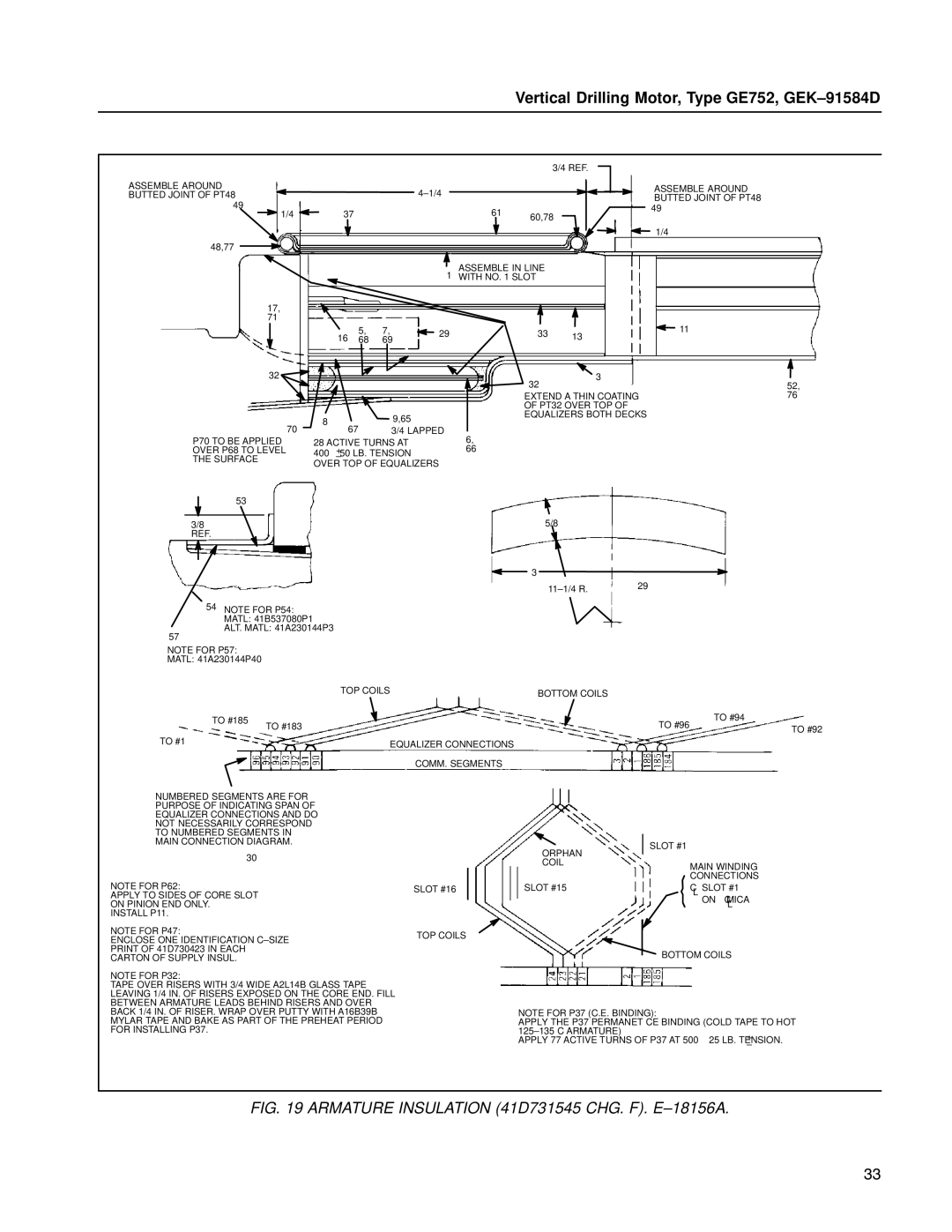

Vertical Drilling Motor, Type GE752, GEK±91584D

|

|

|

| 3/4 REF. |

ASSEMBLE AROUND |

| 4±1/4 |

| ASSEMBLE AROUND |

BUTTED JOINT OF PT48 |

|

| ||

|

| BUTTED JOINT OF PT48 | ||

49 |

|

|

| |

|

| 61 | 49 | |

1/4 | 37 |

| ||

| 60,78 | |||

|

|

|

|

![]()

![]() 1/4

1/4

48,77

ASSEMBLE IN LINE

1 WITH NO. 1 SLOT

17,

71

16 | 5, | 7, | 29 | |

68 | 69 | |||

|

33 13

11

32 ![]()

70

P70 TO BE APPLIED OVER P68 TO LEVEL THE SURFACE

53

89,65

673/4 LAPPED

28 ACTIVE TURNS AT

400 +±50 LB. TENSION OVER TOP OF EQUALIZERS

3

32

EXTEND A THIN COATING OF PT32 OVER TOP OF EQUALIZERS BOTH DECKS

6,

66

52,

76

3/85/8

REF. |

|

3 |

|

11±1/4 R. | 29 |

|

54NOTE FOR P54: MATL: 41B537080P1 ALT. MATL: 41A230144P3

57

NOTE FOR P57:

MATL: 41A230144P40

|

| TOP COILS | BOTTOM COILS |

|

|

|

|

| |

TO #185 | TO #183 |

| TO #96 | TO #94 |

| TO #92 | |||

|

| |||

|

|

|

|

TO #1 | EQUALIZER CONNECTIONS |

| COMM. SEGMENTS |

NUMBERED SEGMENTS ARE FOR

PURPOSE OF INDICATING SPAN OF

EQUALIZER CONNECTIONS AND DO

NOT NECESSARILY CORRESPOND

TO NUMBERED SEGMENTS IN

MAIN CONNECTION DIAGRAM.

30

NOTE FOR P62:

APPLY TO SIDES OF CORE SLOT

ON PINION END ONLY.

INSTALL P11.

NOTE FOR P47:

ENCLOSE ONE IDENTIFICATION C±SIZE

PRINT OF 41D730423 IN EACH

CARTON OF SUPPLY INSUL.

NOTE FOR P32:

TAPE OVER RISERS WITH 3/4 WIDE A2L14B GLASS TAPE LEAVING 1/4 IN. OF RISERS EXPOSED ON THE CORE END. FILL BETWEEN ARMATURE LEADS BEHIND RISERS AND OVER BACK 1/4 IN. OF RISER. WRAP OVER PUTTY WITH A16B39B

MYLAR TAPE AND BAKE AS PART OF THE PREHEAT PERIOD FOR INSTALLING P37.

SLOT #16

TOP COILS

SLOT #1

ORPHAN

COILMAIN WINDING CONNECTIONS

SLOT #15 | C SLOT #1 |

| L |

ON MICA

L

BOTTOM COILS

NOTE FOR P37 (C.E. BINDING):

APPLY THE P37 PERMANET CE BINDING (COLD TAPE TO HOT 125±135 C ARMATURE)

APPLY 77 ACTIVE TURNS OF P37 AT 500

FIG. 19 ARMATURE INSULATION (41D731545 CHG. F). E±18156A.

33