GEK±91584D, Vertical Drilling Motor, Type GE752

CAUTION: Never use an emery cloth on this or any commutator. The abrasive particles on emery cloth scratch the commutator surface and lodge in the groves between commutator segments. The condition creates the possibil- ity of an eventual flashover which could seri- ously damage the machine.

WARNING: Do not come into close proximity of an energized motor during the cleaning pro- cess. The armature commutator and brush rig- ging have a high electrical charge which could cause serious injury or death. Always use a hose tip that is an electrical non±conductor when cleaning with air.

WARNING: When using compressed air for cleaning purposes, flying debris and particles may present a hazard to personnel in the im- mediate area. Personnel should be provided with, and trained in the use of, personal pro- tective equipment as specified by applicable federal or state safety regulations.

3.Run the motor at approximately 1000 rpm.

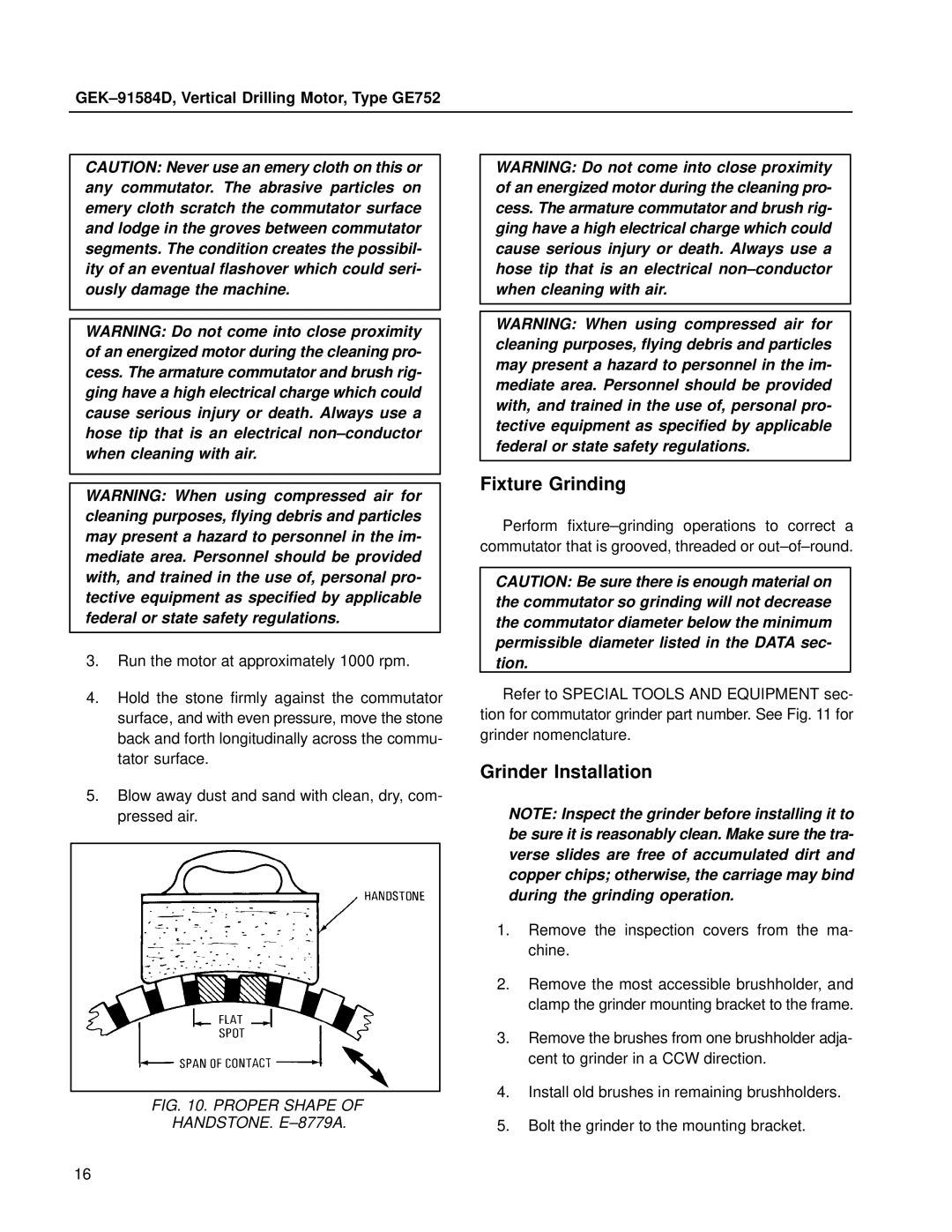

4.Hold the stone firmly against the commutator surface, and with even pressure, move the stone back and forth longitudinally across the commu- tator surface.

5.Blow away dust and sand with clean, dry, com- pressed air.

FIG. 10. PROPER SHAPE OF

HANDSTONE. E±8779A.

WARNING: Do not come into close proximity of an energized motor during the cleaning pro- cess. The armature commutator and brush rig- ging have a high electrical charge which could cause serious injury or death. Always use a hose tip that is an electrical non±conductor when cleaning with air.

WARNING: When using compressed air for cleaning purposes, flying debris and particles may present a hazard to personnel in the im- mediate area. Personnel should be provided with, and trained in the use of, personal pro- tective equipment as specified by applicable federal or state safety regulations.

Fixture Grinding

Perform fixture±grinding operations to correct a commutator that is grooved, threaded or out±of±round.

CAUTION: Be sure there is enough material on the commutator so grinding will not decrease the commutator diameter below the minimum permissible diameter listed in the DATA sec- tion.

Refer to SPECIAL TOOLS AND EQUIPMENT sec- tion for commutator grinder part number. See Fig. 11 for grinder nomenclature.

Grinder Installation

NOTE: Inspect the grinder before installing it to be sure it is reasonably clean. Make sure the tra- verse slides are free of accumulated dirt and copper chips; otherwise, the carriage may bind during the grinding operation.

1.Remove the inspection covers from the ma- chine.

2.Remove the most accessible brushholder, and clamp the grinder mounting bracket to the frame.

3.Remove the brushes from one brushholder adja- cent to grinder in a CCW direction.

4.Install old brushes in remaining brushholders.

5.Bolt the grinder to the mounting bracket.

16