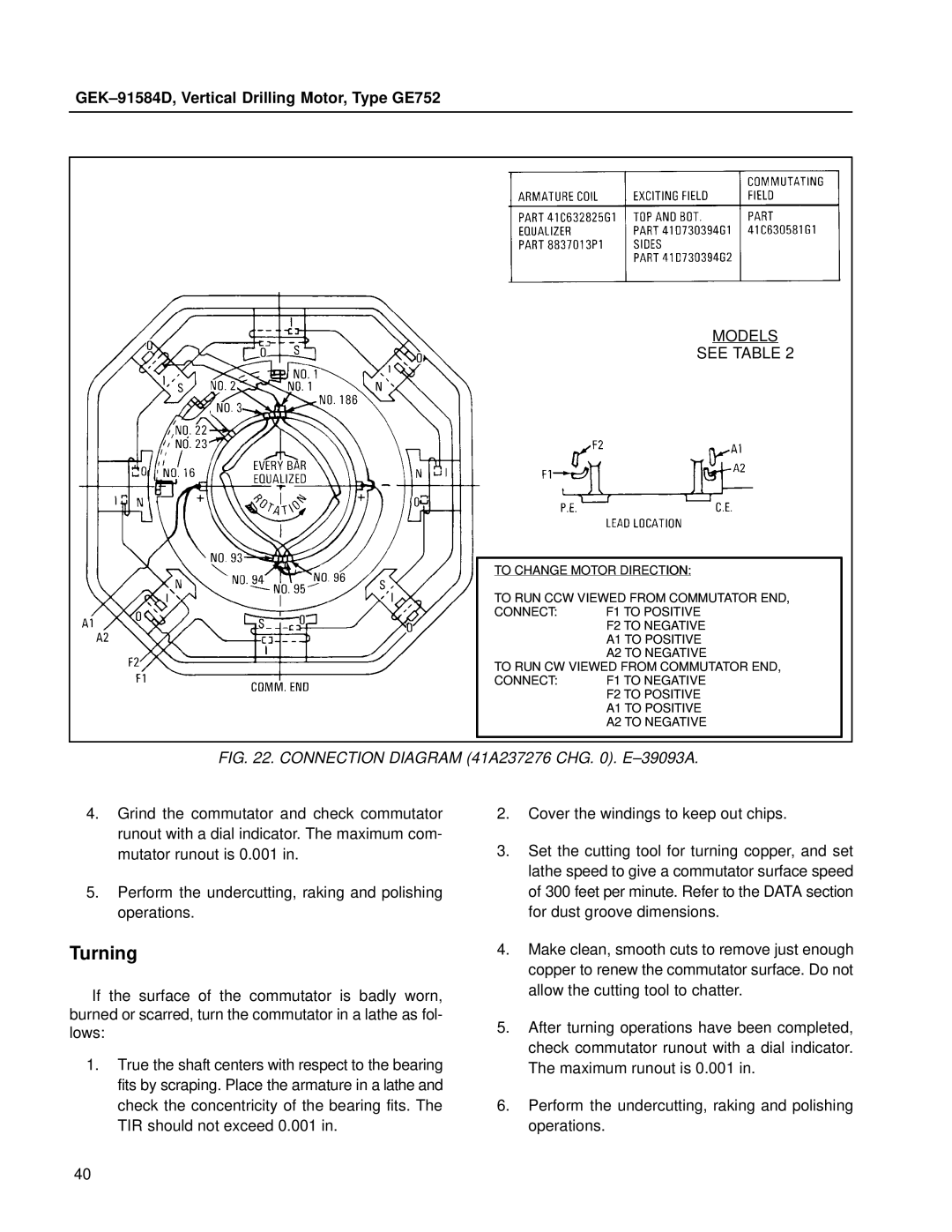

GEK±91584D, Vertical Drilling Motor, Type GE752

MODELS

SEE TABLE 2

TO CHANGE MOTOR DIRECTION:

TO RUN CCW VIEWED FROM COMMUTATOR END,

CONNECT: | F1 TO POSITIVE |

| F2 TO NEGATIVE |

| A1 TO POSITIVE |

| A2 TO NEGATIVE |

TO RUN CW VIEWED FROM COMMUTATOR END, | |

CONNECT: | F1 TO NEGATIVE |

| F2 TO POSITIVE |

| A1 TO POSITIVE |

| A2 TO NEGATIVE |

FIG. 22. CONNECTION DIAGRAM (41A237276 CHG. 0). E±39093A.

4.Grind the commutator and check commutator runout with a dial indicator. The maximum com- mutator runout is 0.001 in.

5.Perform the undercutting, raking and polishing operations.

Turning

If the surface of the commutator is badly worn, burned or scarred, turn the commutator in a lathe as fol- lows:

1.True the shaft centers with respect to the bearing fits by scraping. Place the armature in a lathe and check the concentricity of the bearing fits. The TIR should not exceed 0.001 in.

2.Cover the windings to keep out chips.

3.Set the cutting tool for turning copper, and set lathe speed to give a commutator surface speed of 300 feet per minute. Refer to the DATA section for dust groove dimensions.

4.Make clean, smooth cuts to remove just enough copper to renew the commutator surface. Do not allow the cutting tool to chatter.

5.After turning operations have been completed, check commutator runout with a dial indicator. The maximum runout is 0.001 in.

6.Perform the undercutting, raking and polishing operations.

40