User’s Manual

TransPort Model PT878

Page

TransPort Model PT878

No content intended for this page proceed to next

Information Paragraphs

Safety Issues

Auxiliary Equipment

Local Safety Standards

Waste Electrical and Electronic Equipment Weee Directive

Environmental Compliance

No content intended for this page proceed to next

Features and Capabilities

Programming Site Data

Creating and Managing Sites

Programming Meter Settings

Logging Data

Servicing the PT878

Diagnostics and Troubleshooting

Appendix D. Ultrasonic Thickness Gauge Theory of Operation

Overview

Features and Capabilities

Flowcell

System Description

Electronics Package

Theory of Operation

PT878 and Accessories

Initial Setup

Connection Locations

Making Electrical Connections

Transducer Connections

Power Connections

Input/Output Connections

Description

Infrared Wireless Interface

Charging and Storing the Batteries

Caring for the PT878 Batteries

Replacing the Batteries

Icon Battery Status

Disposing of Batteries

Battery Location

Powering on and OFF

2000/11/30 0953 AM

Velocity, ft/s Signal, dB Delta-T, ns

Velocity, ft/s

Signal, dB

Using the Screen and Keypad

Screen

Icons in the System Tray Function Meaning

Keypad

PT878 Keypad

Help

No content intended for this page proceed to next

Programming Site Data

Entering the Program Menu

Volume, l/s

Vel

Transducer

Wedge Ang Wedge Tmp Wedge SS 1219.2 Cancel

Entering Transducer Parameters

Transducer/Pipe

Entering Transducer Parameters

#43

Pipe #40 Fluid Path Lining

#41

#42

Parameters for Special Transducers

Critical Angle Exceeded Check Angles, Soundspeed

High Angle Error Message Window

Is Too Low Valid range is from 25.000 to

Low Angle Error Message Window

Transducer Spacing Change Window

Transducer Spacing has changed New Spacing Inches 24.493 mm

Other

Confirming Entries

Entering Pipe Parameters

Pipe

70% Cu 30% Ni or 90% Cu 10% Ni

Rolled

None

Annealed or Rolled

Is Too High Valid range is from 3330.052 to 24000.000 ft/s

Transducer/Pipe Invalid Value Too High

Transducer Spacing Change Window

Entering Pipe Parameters

Tar/Epoxy

Sound Speed 2000 Thickness Cancel

Entering Pipe Lining Parameters

Transducer Pipe Lining Fluid Path Material

Entering Pipe Lining Parameters

Tracking Windows?

Entering Fluid Types and Speeds

Transducer Pipe Lining

Fluid

Energy On

Other Water 0-260C Oil Sea Water Oil 22C

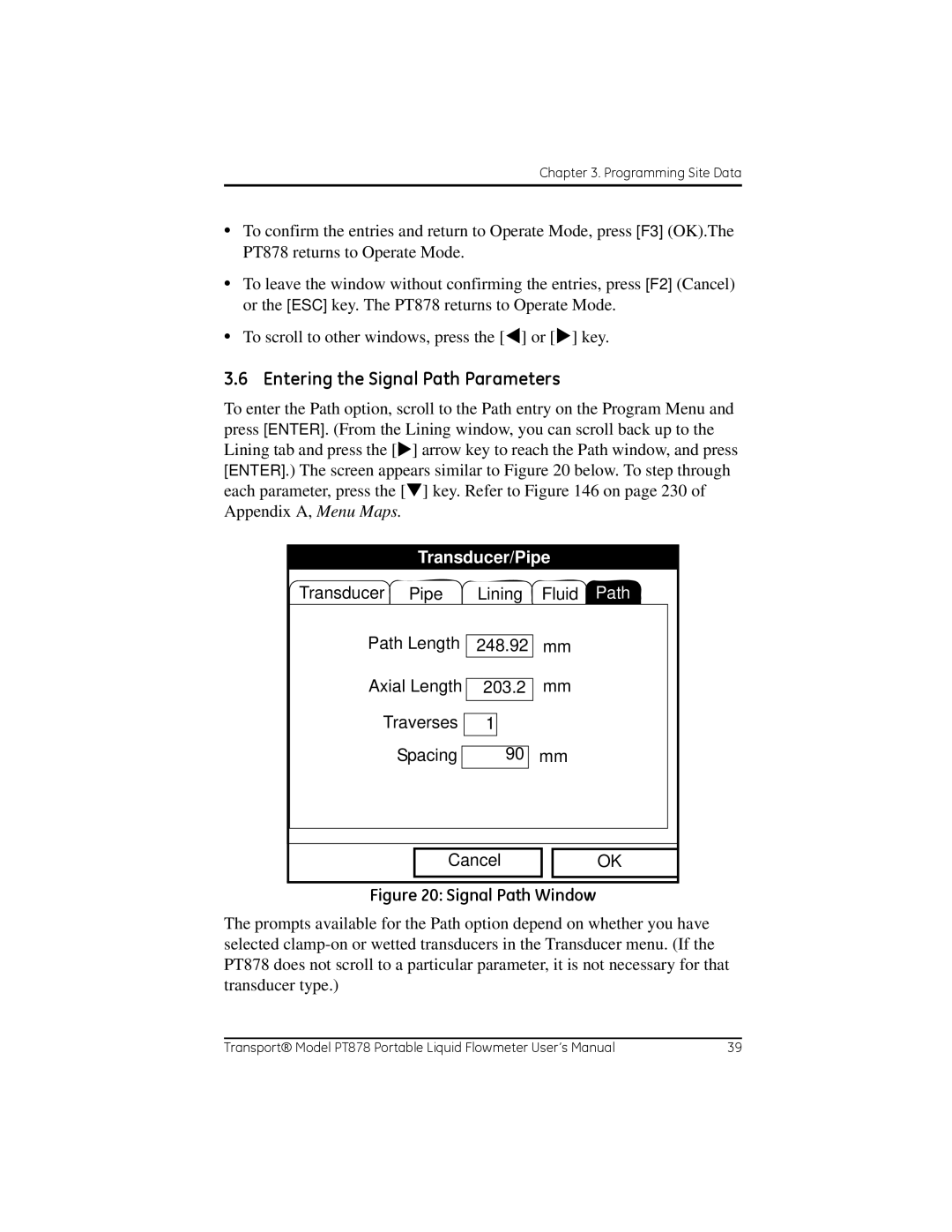

Signal Path Window

Entering the Signal Path Parameters

Path Parameters for Clamp-On Transducers

Path Parameters for Wetted Transducers

Energy Options

Entering the Energy Option Parameters

Energy Option

Entering the Energy Option Parameters

Inputs

Entering Inputs in the Energy Option

Entering Inputs in the Energy Option

Energy Option Inputs

Entering Custom Cp Data in the Energy Option

Custom Cp

Kelvin KJ/kg/K Cancel

Edit Density

Kelvin Kg/m3 Cancel

Programming Site Data

Entering General-Purpose Analog Inputs

Entering Analog Inputs

Delete Cancel

Analog Inputs Option Window Energy Option Activated

Entering Analog Inputs in the Energy Option

Entering Analog Inputs in the Energy Option

Analog Output

Entering the Analog Output

Velocity

Diagnostics

Entering the Analog Output

Digital Output

Entering the Digital Output

If you selected Pulse Totalizer

If you selected Frequency

Stopwatch Totalizer

Label Units Sym Dec Delete Check Done

Entering User Functions

Set User Function

User F1

Text Creation Window

Entering User Functions

Tan Asin

Abs Exp Inv Log

Atan

Reynolds Correctio Calibration FactorInputs

Entering Correction Factors

Entering Reynolds Correction

Correction Factors

Entering Reynolds Correction

Calibration Factor Window

Entering a Calibration Factor

If you entered Single

Edit KFactor Table

Data Source KFactor Cancel

Entering a Calibration Factor

Site

Creating and Managing Sites

Site Manager

Site Manager

Site Manager

File

Site Manager Menu

Site

Creating a New Site

New Site

Use the selected site ‘DEFAULT.SIT’ as a template?

View Yes

DEFAULTRe InfoDEFAULT ResOpen File Default Are You Sure?

Opening an Existing Site

File

Saving a Site

Save the current site DEFAULT.SIT?

Save Site

Saving a Site with a Different Name

Delete Cancel

Save Current Site

Renaming a Site

Refreshing a Site

Delete Confirmation Window

Deleting a Site

Creating a Site Message

File Site Sort Message Info Defaultsit

Delete Cancel

Transferring a Site File to a PC

Printing a Current Site

Transferring a Site File in Text Format to a PC

Transferring a Site to a PC

QuickBeam Window

Transferring a File from a PC to the PT878

Infrared Icon in System Tray

Wireless Link Icon

Sort

Listing Files by Name

Listing Files in Chronological Order

File Site

ABC.SIT 2000/11/30 0953 AM

Displaying and Configuring Data

Format View Measurement

Format Option

Format Decimal Places Fixed Decimal Cancel

Number Format

Format Option

Screen After Format Change

View Option

Set Line Graph Parameters

Limits Option

Limits Option

Measurement Option

Measurement Menu Window

Manager

Customizing the Display Screen

Specifying the Number of Displayed Parameters

Velocity, ft/s

FKeys

Customizing Softkeys

Select a menu item

Configure FKey

Display Screen with Modified Softkey

Contrast

03/15/01 103920

Managing Files The Drive Manager

File Manager

Sort Info SYSLOG.MET

File Manager Menu

Sort Transfer Info SYSLOG.MET

IRInbox Folder Transferred File

Transferring a File to a PC

QuickBeam Window

Infrared Icon in System Tray

Refreshing a File

Wireless Link Icon

Deleting a File

DEFAULTRe InfoDEFAULT ResDelete Site ‘A.SIT’?

File Delete Confirmation

Bytes free Refresh Exit

File Sort

GLOBAL.By Date

09/04/02

To return to Operate Mode, press ESC or F3 Exit

Accessing Meter Data -The About Option

Programming Meter Settings

Meter

Entering the Meter Menu

Units

Units English Metric Date 2000/11/1 Time 100853 Cancel

Meter Settings

Selecting Measurement Units

8Ahr NiCd

Battery Charger

Battery Charger

Condition Battery

Entering Date and Time

Entering Date and Time

Locale

Changing Date and Time Appearance

Display Options

Display

Changing Date and Time Appearance

Changing Date and Time Appearance

Display Options

Adjusting the Contrast

Display

Setting Backlight Timeout

Change Language

Changing the Display Language

650.0

Changing Communications Settings

Communications

None Cancel

Changing Communications Settings

Reset Both

Resetting Forward and Reverse Totals

Totals

User Function Tables

Setting Up User Tables

UserTable1 Delete Cancel

Edit User Table

UserTable1 Cancel

Taking a Bitmap Capture of a Current Screen

Logging Data

New Log Test Units

Entering the Logging Menu

Log Manager

Log Manager

Rename S03/01/01

File Menu

New

Ed Log State Finished

Create New Log

Setting up a New Log

Secs

Cancel Activate

Setting up a New Log

Log Measurements Window

General Measurements

Select Measurement Window

Copying Cloning a Selected Log

Deleting a Log

Renaming a Log

Log Manager FileDelete

DEFAULTRe InfoDEFAULT ResDelete Log ‘555.LOG?’

Deleting All Logs

Refreshing the Log Manager Screen

Start Time 132341 PM End Time 135341 PM

Printing a Log

52.0 Start Date 2003/03/01 End Date

Enter Time

Transferring a Log to a PC

Log

Log Menu

Start

Restarting a Log

Stopping Pausing a Log

Ending a Log

View All Sites

Stopping All Logs

Restarting All Logs

Ending All Logs

View

View Menu

Details

Log Info

Displaying Log Details

AAA.LOG Velocity, ft/s

Displaying Log Data in Graphical Form

297 289 2001/03/01 132341 PM 135341 PM Scale Time Exit

Axis Window

AAA.LOGY-AxisDew Point, C

52.0

123.LOG

Displaying Log Data in Spreadsheet Form

Sort By Name

Sort Menu

Listing Logs by Name

Listing Logs in Chronological Order

Servicing the PT878

Test

Entering the Service Menu

Printing Reports

Reports Drive Contents

Current Site

Printout of a Typical Drive Report

Setting up the Thickness Gauge

Material Window

Thickness Gauge Measure

Entering the Material and Soundspeed

Display Graph Velocity Zero Material

Measuring Thickness in Numeric Format

Thickness, mm

Velocity Zero Material

Displaying the Receive Signal in Graphical Format

Signal

Graph

Graph Window in Zoom Format

Out Display

Display Graph Velocity

Calibrating the Thickness Gauge Transducer

Zero

Dual-Point Calibration

Dual-Point Calibration

Soundspeed Window

Calculating Velocity Pipe Material Soundspeed

Set

Press Set to Commit Value Calculated 22129. Current Cancel

Display Graph

Zero Material

Programming the Thickness Gauge

Programming

Thickness Gauge Setup

Programming the Thickness Gauge

Diagnostics Window

Displaying Diagnostic Parameters

Calibrating the Analog Output

Calibrating the Analog Output and Inputs

Analog Output

Enter

Analog Output

Input# Low Read High 20 mA Calibrate Reset Cancel

Calibrating Inputs

Calibrate/Test I/O

Calibrating Inputs

Signal Setup

Setting up Signal Parameters

Signal Para

Setting up Signal Parameters

Setting up Signal Parameters

Pulse/Code

Setting up Peak Detection

Signal Para

Peak Detect

Enter

Pulse/Code

Signal Para Peak Detect

Transmit Code Auto Cancel

Selecting the Transmit Code

Signal Error Limits

Setting Error Limits

Setting Error Limits

Setting Error Limits

Test Screen

Service

Test Option

Reports

Functioning Test Screen

Testing the Screen

Test Keys Window

Testing the Keys

This test should automatically

Testing the Watchdog Timer Circuit

Factory Defaults Restart your meter

Press ‘No’ to cancel the test

Direction Percent Gain Upstream Stopped

Setting Impulse Response

Taking Wave Samples for Diagnosis

Applying a Stored Signal for Diagnosis

Service Battery Form

Testing the Battery

Factory Defaults

Resetting to Factory Default Parameters

Updating PT878 Software

Choose ‘Cancel’ to exit or ‘OK’ to continue

Update Flash

Updating Software Via IrOBEX

Updating Software Via IrCOMM

12.2a Setting up the PC

12.2b Installing New Software

12.2b Installing New Software

Send File Window in the Transfer Menu

No content intended for this page proceed to next

Diagnostics and Troubleshooting

Error Messages

Error Code Messages

Velocity Range

Diagnostic Parameters

Displays raw upstream signal correlated With transmit signal

Fluid Problems

Flowcell Problems

Pipe Problems

Wetted Transducer Problems

Transducer Problems

Physical Damage

Clamp-on Transducer Problems

Press Menu

Relocating Transducers

Enclosure

Specifications

Overall Hardware Configuration

Size/Weight

EMC

Electrical

Environmental

Operational Specifications

Transducer Clamp-On Ultrasonic Flow Transducers

Temperature Transducers

Available Options

Thickness Measuring Mode

Program Menu

Appendix A. Menu Maps

No content intended for this page proceed to next

Site

Program Menu with Pipe Option

YYYY/MM MM/DD DD/MM

Logging

Service

Page

Transducer Option

Lining Option

Fluid Option

Path Option

Energy Option

Analog Input Option

Analog Output Option

Digital Output Option

User Functions Option

Correction Factors Option

Communications Option

No content intended for this page proceed to next

Top View of 180 Transducer Installation

Appendix B. Measuring P and L Dimensions

Determining the Pipe Coupling Length

Appendix B. Measuring P and L Dimensions

No content intended for this page proceed to next

Guidelines for RTD Installation

Appendix C. Temperature Transmitter Installation

Assembling the Clamping Fixture

Mounting RTDs on the Pipe

Mounting the RTD to the Pipe

Connecting the RTD to the 4 to 20-mA Transmitter

Connection Locations

Connecting the Transmitter to the PT878

No content intended for this page proceed to next

Appendix D. Ultrasonic Thickness Gauge Theory of Operation

Factors Affecting Performance and Accuracy

Transducer

Transducer Positioning/Alignment

Taper or Eccentricity

Calibration

Acoustic Properties of the Material

Product Identification

Appendix E. Material Safety Data Sheet for Couplant

Hazardous Ingredients

Fire and Explosion Hazard Data

Physical Data nominal

Reactivity Data

Storage and Handling Information

Health Hazard and First Aid Data

Soundsafe

Control Measures

IrDA Compatibility of Windows Operating Systems

Appendix F. Establishing IR Communications

Windows 2000/XP

Appendix G. Glossary

Appendix G. Glossary

Appendix G. Glossary

Appendix G. Glossary

Index

Cont

Index

Index

Index

Index

Index

Cont

Index

Cont

Index

No content intended for this page proceed to next

Warranty

Return Policy

TÜV

Conformite

Erklärung

Page

Ireland

Customer Support Centers