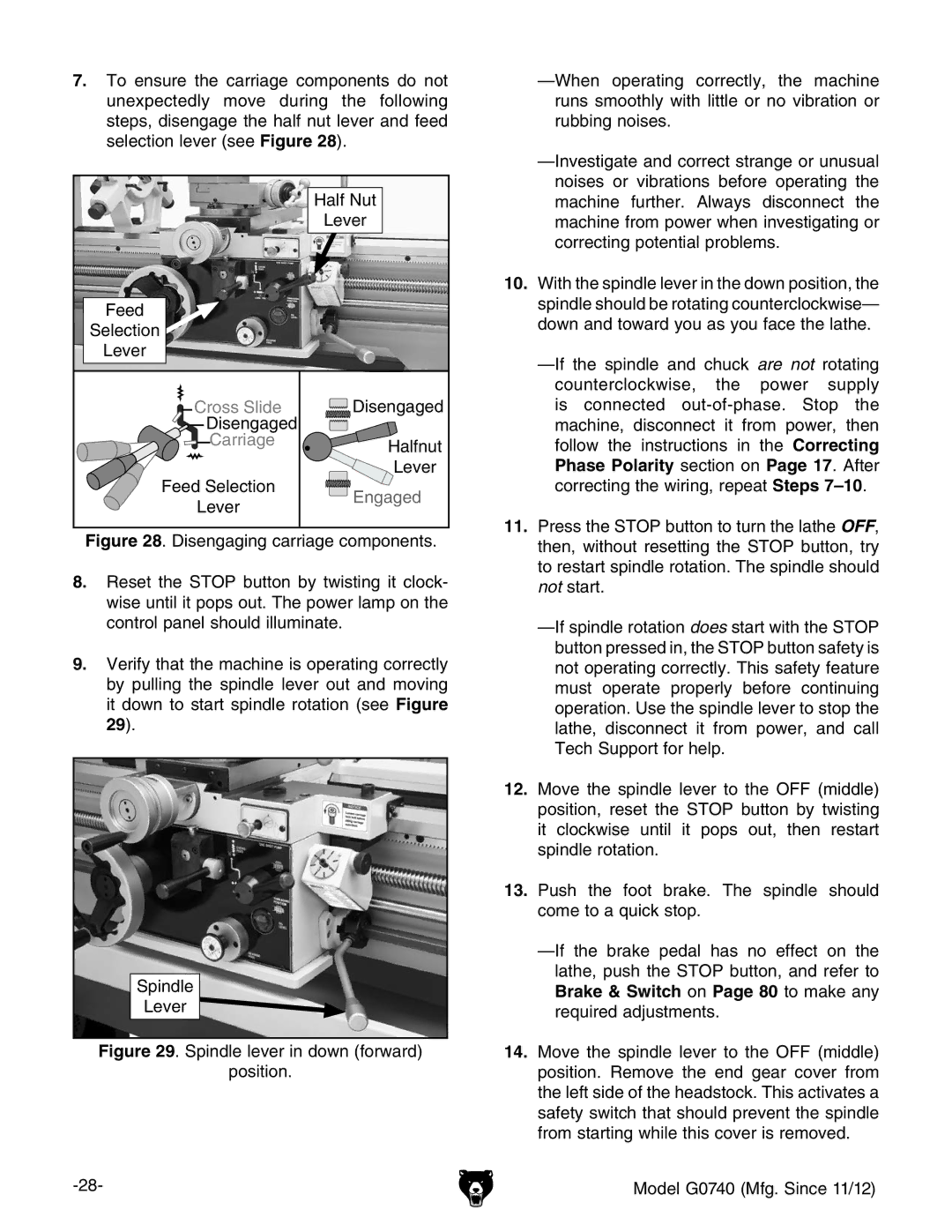

7.To ensure the carriage components do not unexpectedly move during the following steps, disengage the half nut lever and feed selection lever (see Figure 28).

Half Nut

Lever

Feed

Selection

Lever

Cross Slide | Disengaged | |

Disengaged |

| |

Carriage | Halfnut | |

| ||

Feed Selection | Lever | |

Engaged | ||

Lever | ||

|

Figure 28. Disengaging carriage components.

8.Reset the STOP button by twisting it clock- wise until it pops out. The power lamp on the control panel should illuminate.

9.Verify that the machine is operating correctly by pulling the spindle lever out and moving it down to start spindle rotation (see Figure 29).

Spindle

Lever

Figure 29. Spindle lever in down (forward)

position.

—When operating correctly, the machine runs smoothly with little or no vibration or rubbing noises.

—investigate and correct strange or unusual noises or vibrations before operating the machine further. Always disconnect the machine from power when investigating or correcting potential problems.

10.With the spindle lever in the down position, the spindle should be rotating counterclockwise— down and toward you as you face the lathe.

11.press the STOP button to turn the lathe OFF, then, without resetting the STOP button, try to restart spindle rotation. The spindle should not start.

12.move the spindle lever to the OFF (middle) position, reset the STOP button by twisting it clockwise until it pops out, then restart spindle rotation.

13.push the foot brake. The spindle should come to a quick stop.

14.move the spindle lever to the OFF (middle) position. Remove the end gear cover from the left side of the headstock. This activates a safety switch that should prevent the spindle from starting while this cover is removed.

Model G0740 (Mfg. Since 11/12)