Leadscrew End Play

Adjustment

After a long period of time, you may find that the leadscrew develops a small amount of end play. This end play can be removed with an easy adjustment.

Tools Needed: | Qty |

Hex Wrench 3mm | 1 |

Wrench 24mm | 1 |

To remove leadscrew end play: |

|

1.DISCONNECT LATHE FROM POWER!

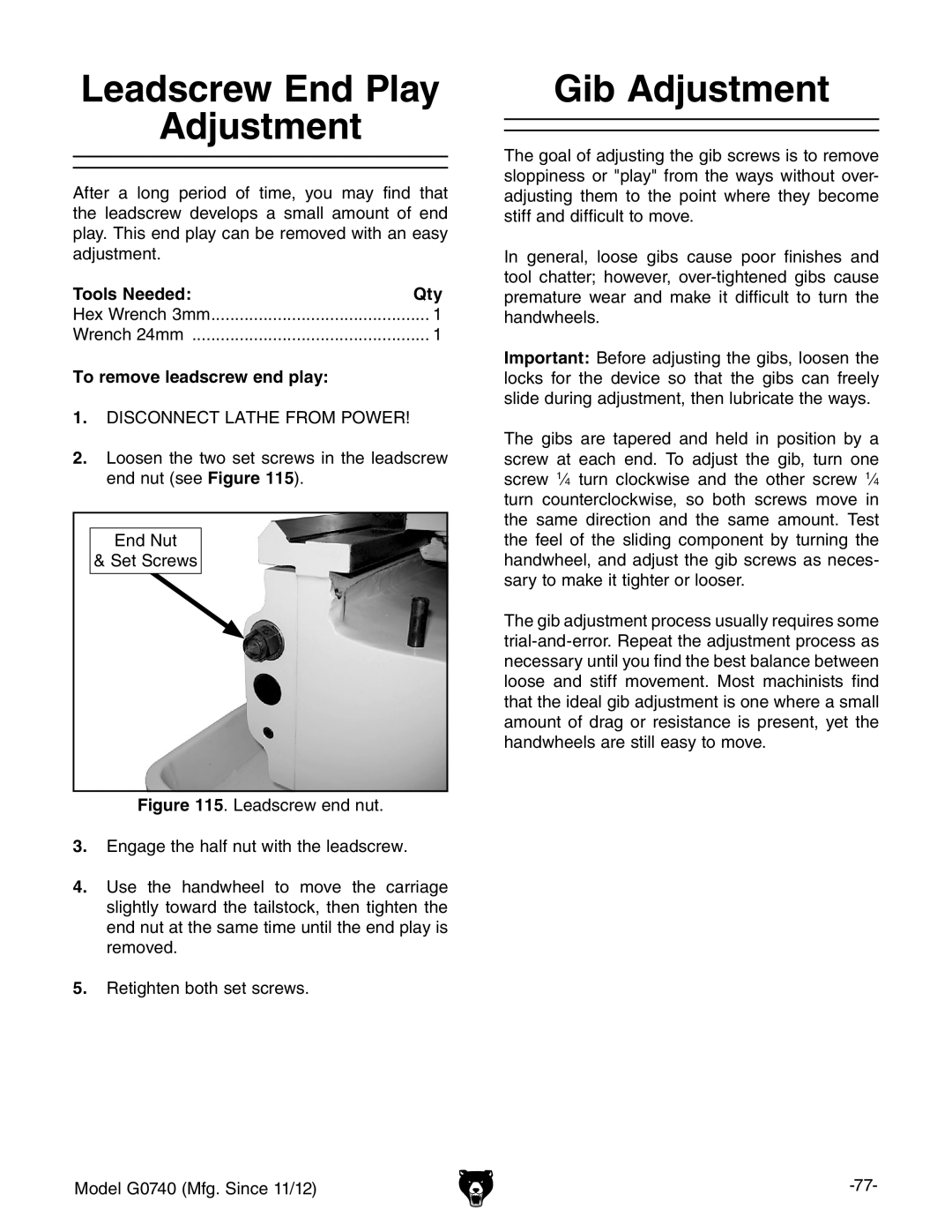

2.loosen the two set screws in the leadscrew end nut (see Figure 115).

End Nut

& Set Screws

Figure 115. Leadscrew end nut.

3.engage the half nut with the leadscrew.

4.use the handwheel to move the carriage slightly toward the tailstock, then tighten the end nut at the same time until the end play is removed.

5.retighten both set screws.

Model G0740 (Mfg. Since 11/12)

Gib Adjustment

The goal of adjusting the gib screws is to remove sloppiness or "play" from the ways without over- adjusting them to the point where they become stiff and difficult to move.

In general, loose gibs cause poor finishes and tool chatter; however,

Important: Before adjusting the gibs, loosen the locks for the device so that the gibs can freely slide during adjustment, then lubricate the ways.

The gibs are tapered and held in position by a screw at each end. To adjust the gib, turn one screw 1⁄4 turn clockwise and the other screw 1⁄4 turn counterclockwise, so both screws move in the same direction and the same amount. Test the feel of the sliding component by turning the handwheel, and adjust the gib screws as neces- sary to make it tighter or looser.

The gib adjustment process usually requires some