INTRODUCTION

Machine Description |

| Manual Accuracy |

|

|

|

|

|

|

The Model G0740 metal lathe is used to remove material from a rotating workpiece, which is held in place on the spindle with a chuck or face- plate. The cutting tool is mounted on the car- riage or tailstock and moved against the spinning workpiece to perform the cut.

This lathe has 16 available spindle speeds and powered feed for the carriage and cross slide. The use of the cutting fluid system and spindle brake is optional.

Typical cutting operations for a metal lathe include facing, turning, parting, drilling, reaming, grooving, knurling, and threading. There are a wide variety of tools and workpiece holding devices available for each of these operations.

Contact Info

We stand behind our machines. If you have any questions or need help, use the information below to contact us. Before contacting, please get the serial number and manufacture date of your machine. This will help us help you faster.

Grizzly Technical Support 1203 Lycoming Mall Circle Muncy, PA 17756 Phone: (570)

Email: techsupport@grizzly.com

We want your feedback on this manual. What did you like about it? Where could it be improved? Please take a few minutes to give us feedback.

Grizzly Documentation Manager

P.O. Box 2069

Bellingham, WA

Email: manuals@grizzly.com

Model G0740 (Mfg. Since 11/12)

We are proud to provide a

We made every effort to be exact with the instruc- tions, specifications, drawings, and photographs contained inside. sometimes we make mistakes, but our policy of continuous improvement also means that sometimes the machine you receive will be slightly different than what is shown in the manual.

if you find this to be the case, and the difference between the manual and machine leaves you confused about a procedure, check our website for an updated version. We post current manuals and manual updates for free on our website at www.grizzly.com.

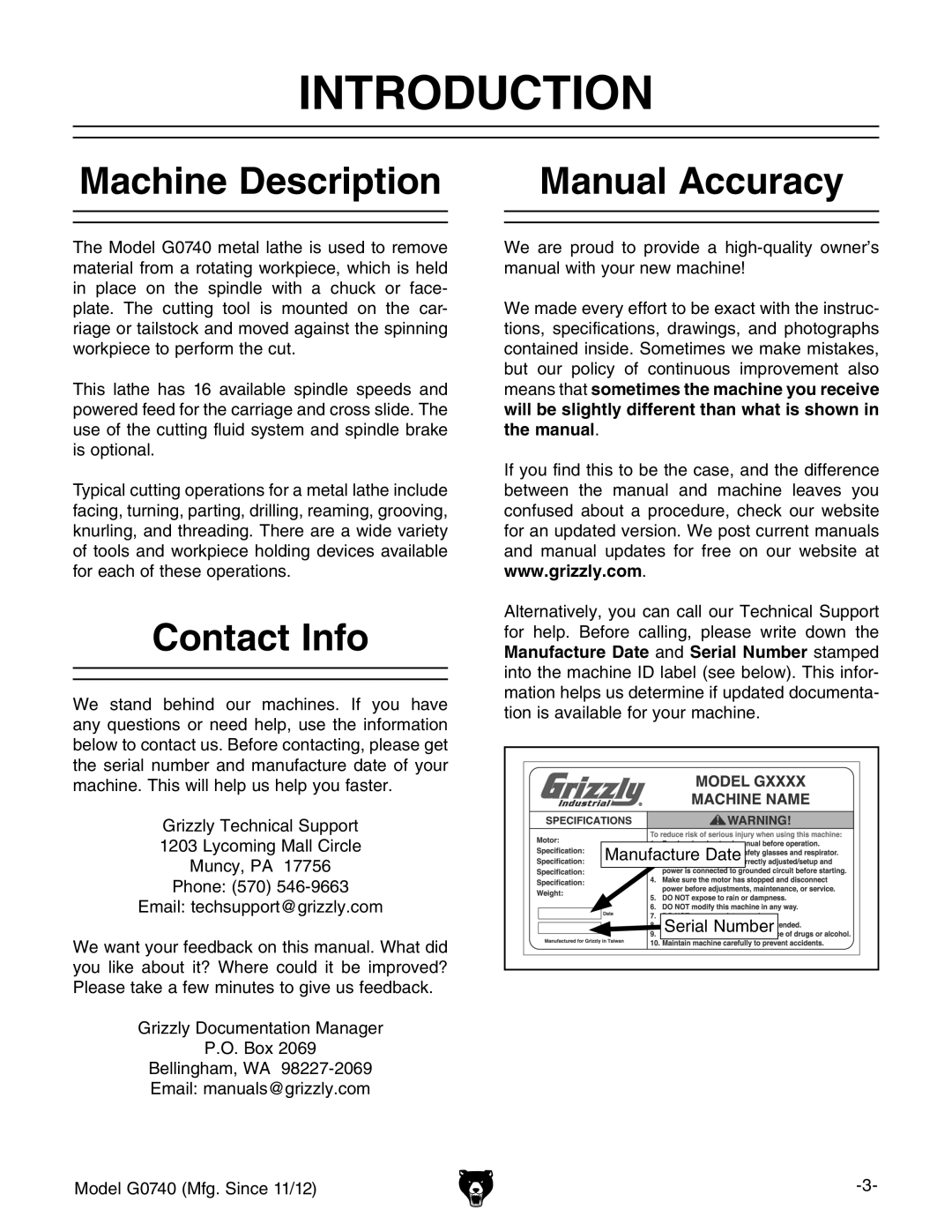

alternatively, you can call our technical support for help. before calling, please write down the Manufacture Date and Serial Number stamped into the machine iD label (see below). this infor- mation helps us determine if updated documenta- tion is available for your machine.

manufacture Date |

serial number |