Lubrication

Use the schedule and information in the chart below as a daily guide for lubrication tasks. We recommend using Grizzly Model T23962 or T23963 lubricants (see Accessories, Page 62) for most of the lubrication tasks.

Lubrication Task | Frequency | Page |

Ref. | ||

Headstock | Daily | 66 |

Daily | 67 | |

Apron | Daily | 67 |

As Needed | 67 | |

Longitudinal Leadscrew | Daily | 68 |

Ball Oilers & Oil Cup | Daily | 68 |

End Gears | Annually | 69 |

NOTICE

The recommended lubrication is based on

Failure to follow reasonable lubrication practices as instructed in this manual could lead to premature failure of lathe compo- nents and will void the warranty.

Model G0740 (Mfg. Since 11/12)

Headstock

Oil Type..... Grizzly T23963 or ISO 32 Equivalent

Oil Amount | 7.4 Quarts |

Check/Add Frequency | Daily |

Change Frequency |

The headstock gearing is lubricated by an oil bath that distributes the lubricant with the motion of the gears, much like an automotive manual transmis- sion.

Checking Oil Level

The headstock reservoir has the proper amount of oil when the oil level in the sight glass is approxi- mately halfway. The oil sight glass is located on the right side of the headstock, as shown in Figure 99.

Headstock

Oil Sight

Glass

Figure 99. Location of headstock oil sight glass.

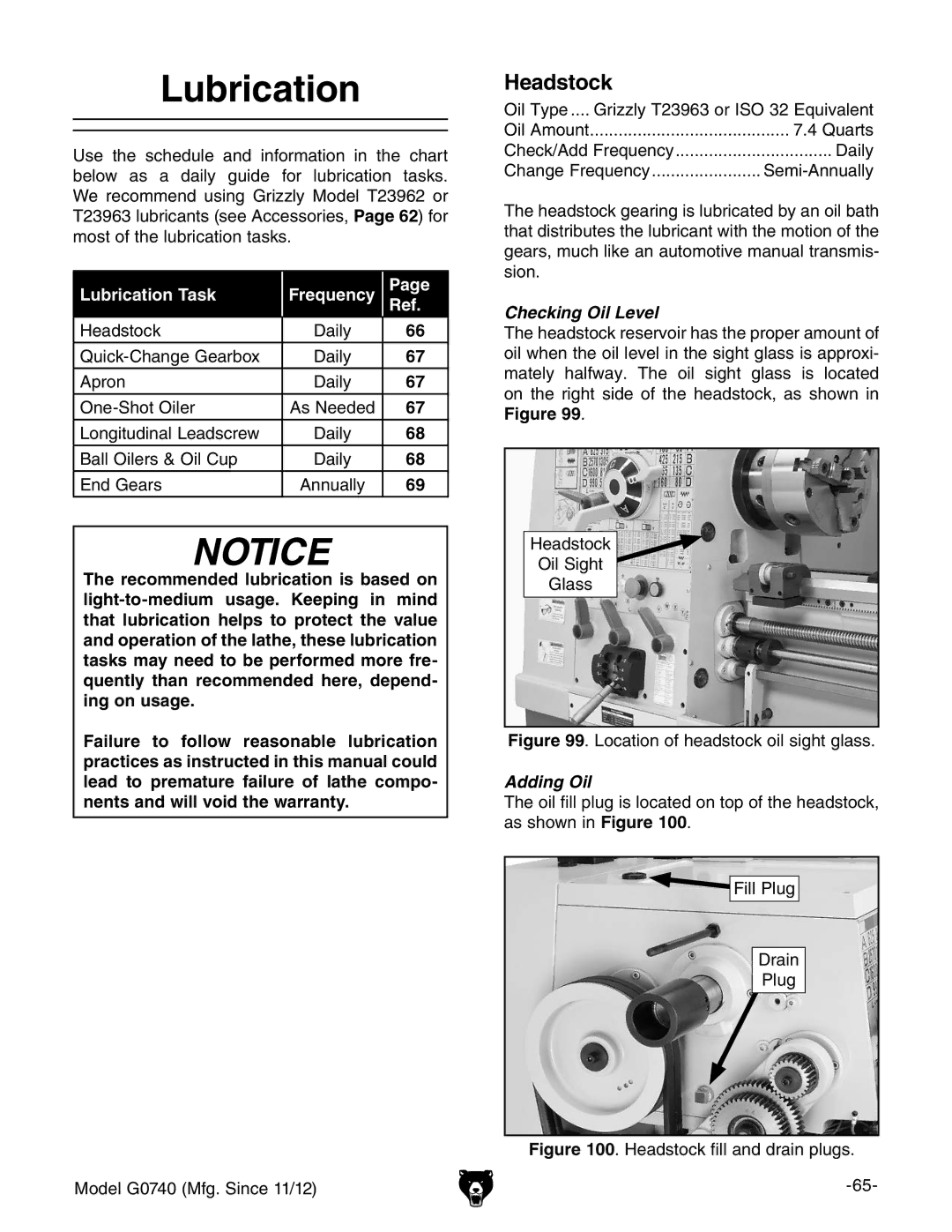

Adding Oil

The oil fill plug is located on top of the headstock, as shown in Figure 100.

Fill Plug

Drain

Plug