Faceplate

refer to the prior Chuck Installation and Chuck Removal sections for instructions on installing or removing the faceplate.

the faceplate included with your lathe can be used for a wide range of operations, including machining

the tools needed for mounting a workpiece will vary depending on the type of setup you have.

Machining

Failure to properly secure a workpiece to the faceplate could cause the workpiece to be thrown from the lathe with deadly force at the operator or bystanders. Use a minimum of THREE independent clamping devices to hold the workpiece onto the faceplate.

Model G0740 (Mfg. Since 11/12)

To mount a non-concentric workpiece to the faceplate:

1.DisConneCt lathe From poWer!

2.protect the bedway with a piece of plywood.

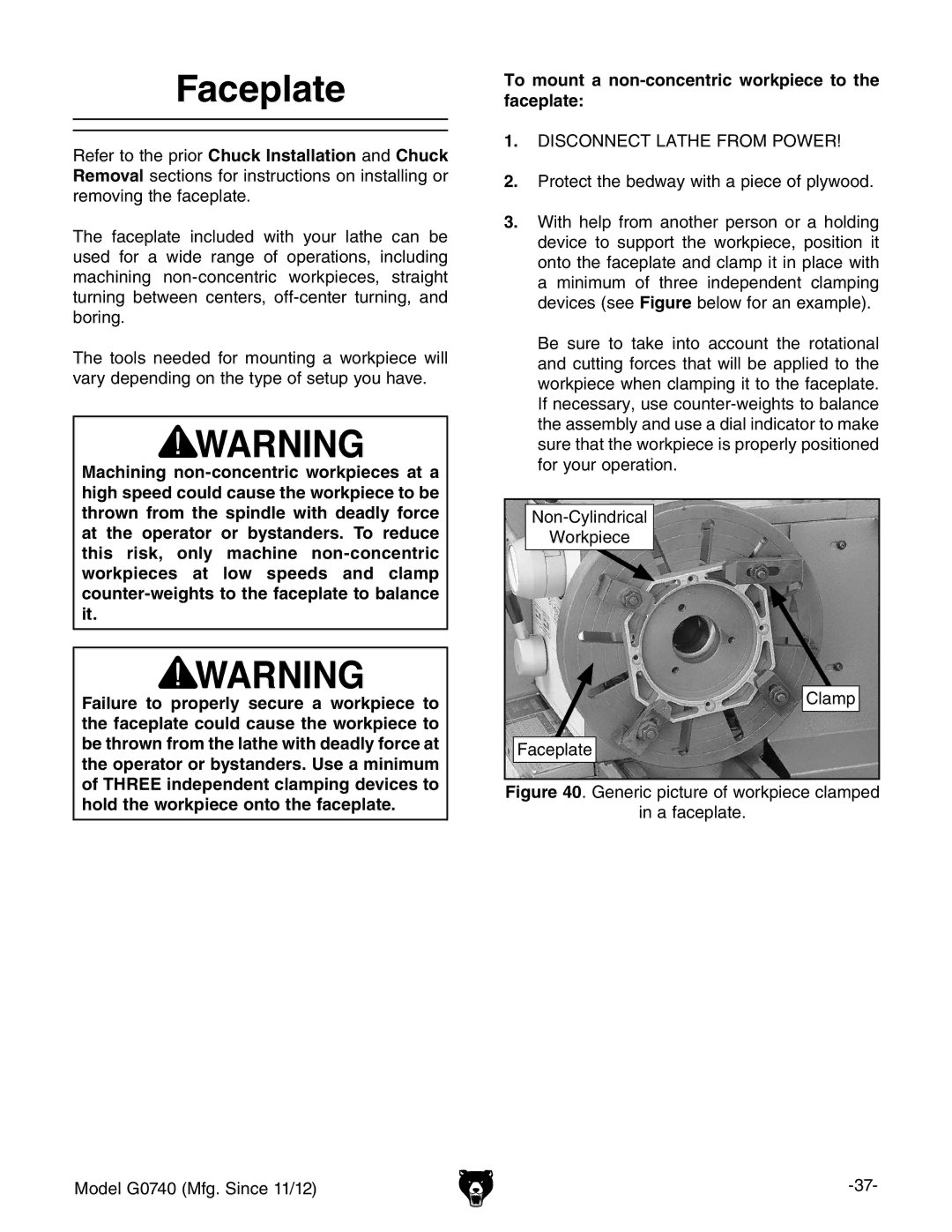

3.With help from another person or a holding device to support the workpiece, position it onto the faceplate and clamp it in place with a minimum of three independent clamping devices (see figure below for an example).

be sure to take into account the rotational and cutting forces that will be applied to the workpiece when clamping it to the faceplate. if necessary, use

Workpiece

Clamp

Faceplate