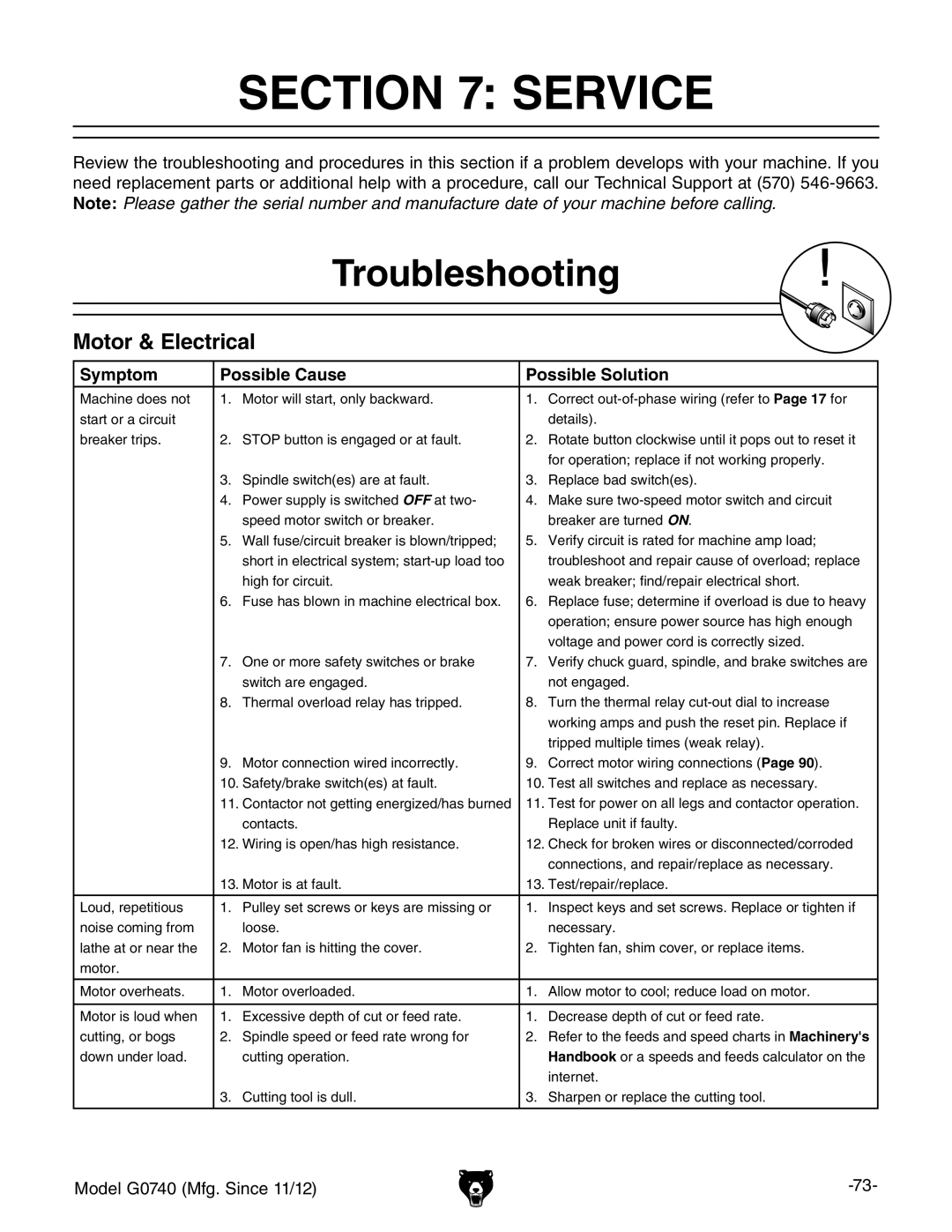

SECTION 7: SERVICE

Review the troubleshooting and procedures in this section if a problem develops with your machine. If you need replacement parts or additional help with a procedure, call our Technical Support at (570)

Troubleshooting

Motor & Electrical

Symptom | Possible Cause | Possible Solution | ||

Machine does not | 1. | motor will start, only backward. | 1. | Correct |

start or a circuit |

|

|

| details). |

breaker trips. | 2. | stop button is engaged or at fault. | 2. | rotate button clockwise until it pops out to reset it |

|

|

|

| for operation; replace if not working properly. |

| 3. | spindle switch(es) are at fault. | 3. | replace bad switch(es). |

| 4. | power supply is switched OFF at two- | 4. | make sure |

|

| speed motor switch or breaker. |

| breaker are turned ON. |

| 5. | Wall fuse/circuit breaker is blown/tripped; | 5. | Verify circuit is rated for machine amp load; |

|

| short in electrical system; |

| troubleshoot and repair cause of overload; replace |

|

| high for circuit. |

| weak breaker; find/repair electrical short. |

| 6. | Fuse has blown in machine electrical box. | 6. | replace fuse; determine if overload is due to heavy |

|

|

|

| operation; ensure power source has high enough |

|

|

|

| voltage and power cord is correctly sized. |

| 7. | one or more safety switches or brake | 7. | Verify chuck guard, spindle, and brake switches are |

|

| switch are engaged. |

| not engaged. |

| 8. | thermal overload relay has tripped. | 8. | turn the thermal relay |

|

|

|

| working amps and push the reset pin. Replace if |

|

|

|

| tripped multiple times (weak relay). |

| 9. | motor connection wired incorrectly. | 9. | Correct motor wiring connections (Page 90). |

| 10. safety/brake switch(es) at fault. | 10. test all switches and replace as necessary. | ||

| 11. Contactor not getting energized/has burned | 11. test for power on all legs and contactor operation. | ||

|

| contacts. |

| Replace unit if faulty. |

| 12. Wiring is open/has high resistance. | 12. Check for broken wires or disconnected/corroded | ||

|

|

|

| connections, and repair/replace as necessary. |

| 13. motor is at fault. | 13. test/repair/replace. | ||

|

|

|

|

|

Loud, repetitious | 1. | pulley set screws or keys are missing or | 1. | inspect keys and set screws. Replace or tighten if |

noise coming from |

| loose. |

| necessary. |

lathe at or near the | 2. | motor fan is hitting the cover. | 2. | tighten fan, shim cover, or replace items. |

motor. |

|

|

|

|

|

|

|

|

|

Motor overheats. | 1. | motor overloaded. | 1. | allow motor to cool; reduce load on motor. |

|

|

|

|

|

Motor is loud when | 1. | excessive depth of cut or feed rate. | 1. | Decrease depth of cut or feed rate. |

cutting, or bogs | 2. | spindle speed or feed rate wrong for | 2. | refer to the feeds and speed charts in Machinery's |

down under load. |

| cutting operation. |

| Handbook or a speeds and feeds calculator on the |

|

|

|

| internet. |

| 3. | Cutting tool is dull. | 3. | sharpen or replace the cutting tool. |

|

|

|

|

|

Model G0740 (Mfg. Since 11/12) |