Coolant System

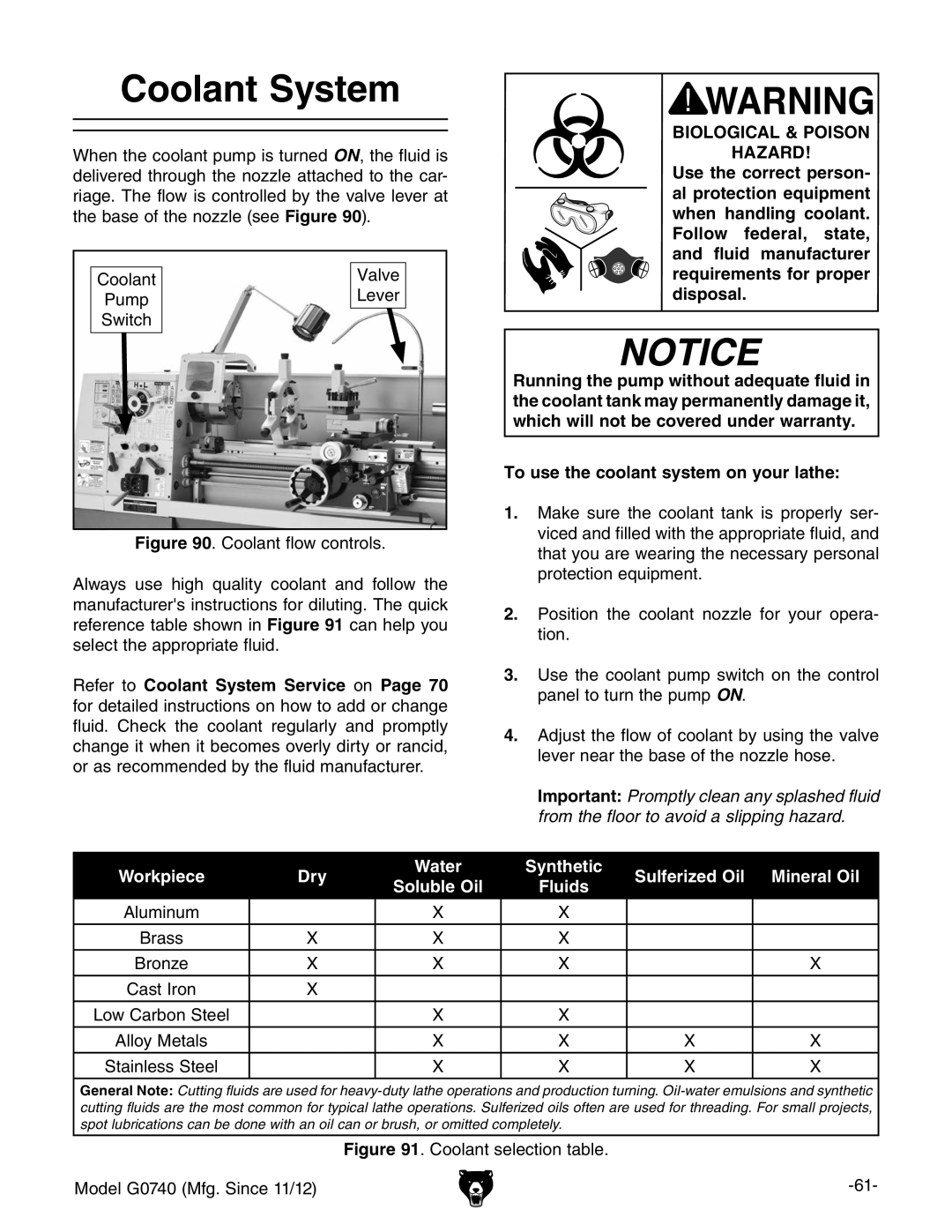

When the coolant pump is turned ON, the fluid is delivered through the nozzle attached to the car- riage. The flow is controlled by the valve lever at the base of the nozzle (see Figure 90).

Coolant |

| Valve |

Pump |

| Lever |

Switch |

|

|

|

|

|

Figure 90. Coolant flow controls.

Always use high quality coolant and follow the manufacturer's instructions for diluting. The quick reference table shown in Figure 91 can help you select the appropriate fluid.

Refer to Coolant System Service on Page 70 for detailed instructions on how to add or change fluid. Check the coolant regularly and promptly change it when it becomes overly dirty or rancid, or as recommended by the fluid manufacturer.

BIOLOGICAL & POISON

HAZARD!

Use the correct person- al protection equipment when handling coolant. Follow federal, state, and fluid manufacturer requirements for proper disposal.

Running the pump without adequate fluid in the coolant tank may permanently damage it, which will not be covered under warranty.

To use the coolant system on your lathe:

1.make sure the coolant tank is properly ser- viced and filled with the appropriate fluid, and that you are wearing the necessary personal protection equipment.

2.position the coolant nozzle for your opera- tion.

3.use the coolant pump switch on the control panel to turn the pump ON.

4.adjust the flow of coolant by using the valve lever near the base of the nozzle hose.

Important: Promptly clean any splashed fluid from the floor to avoid a slipping hazard.

Workpiece | Dry | Water | Synthetic | Sulferized Oil | Mineral Oil | |

Soluble Oil | Fluids | |||||

|

|

|

| |||

Aluminum |

| X | X |

|

| |

Brass | X | X | X |

|

| |

|

|

|

|

|

| |

Bronze | X | X | X |

| X | |

|

|

|

|

|

| |

Cast Iron | X |

|

|

|

| |

|

|

|

|

|

| |

Low Carbon Steel |

| X | X |

|

| |

|

|

|

|

|

| |

Alloy Metals |

| X | X | X | X | |

|

|

|

|

|

| |

Stainless Steel |

| X | X | X | X | |

|

|

|

|

|

|

General Note: Cutting fluids are used for

Figure 91. Coolant selection table.

Model G0740 (Mfg. Since 11/12) |