Compound Rest |

|

|

|

|

|

|

|

|

The compound rest handwheel has an indirect- read graduated scale. This means that the dis- tance shown on the scale represents the actual distance the cutting tool moves. The base of the compound rest has another graduated scale used for setting the cutting tool to a specific angle.

Graduated Dial |

|

Increments | 0.001" (0.02mm) |

One Full Revolution | 0.100" (2.54mm) |

Tool Needed | Qty |

Wrench 14mm | 1 |

To set the compound rest at a certain angle:

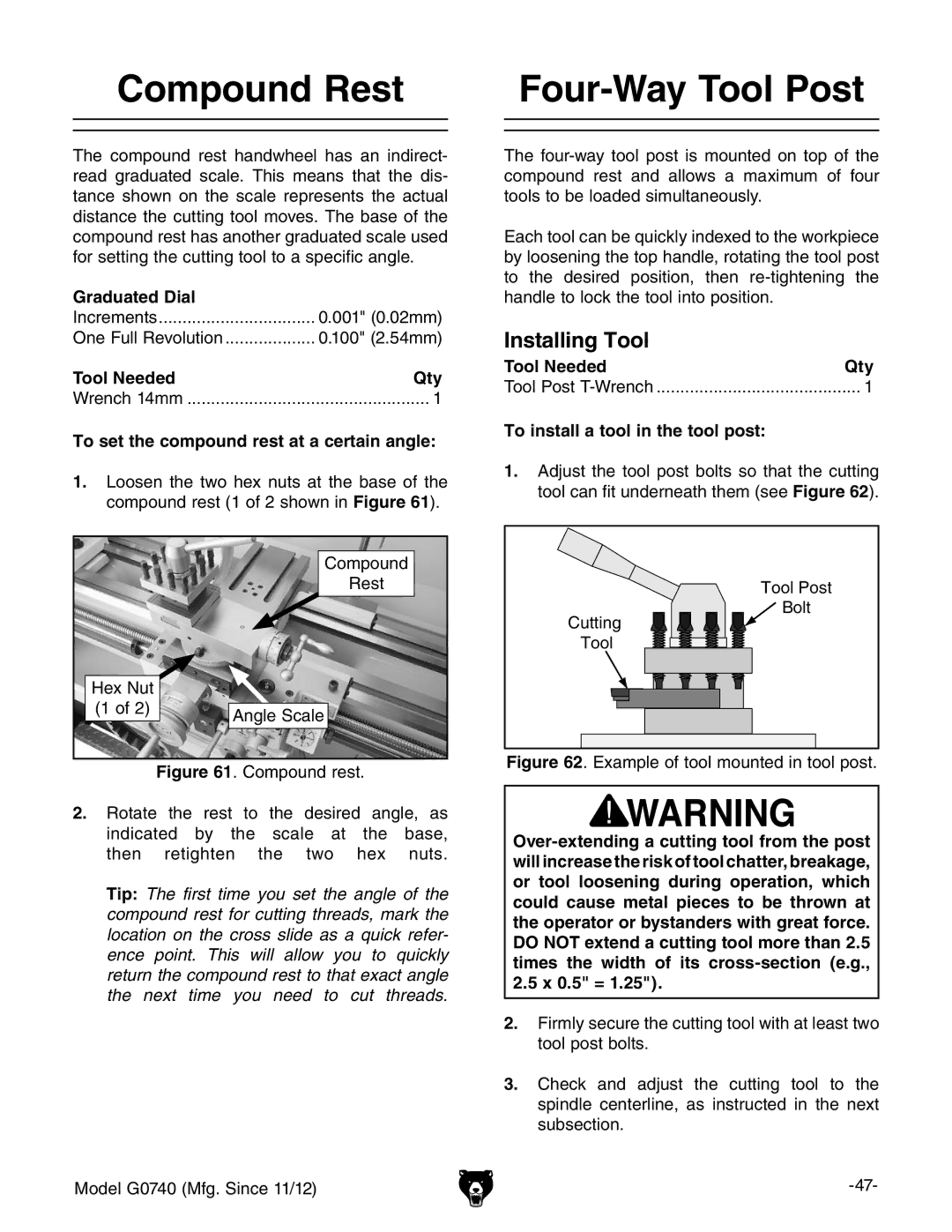

1.loosen the two hex nuts at the base of the compound rest (1 of 2 shown in Figure 61).

Compound |

Rest |

The

Each tool can be quickly indexed to the workpiece by loosening the top handle, rotating the tool post to the desired position, then

Installing Tool |

|

Tool Needed | Qty |

Tool Post | 1 |

To install a tool in the tool post: |

|

1.Adjust the tool post bolts so that the cutting tool can fit underneath them (see Figure 62).

Tool Post

Hex Nut |

|

(1 of 2) | Angle Scale |

|

Cutting

Tool

Bolt

Figure 61. Compound rest.

2.rotate the rest to the desired angle, as indicated by the scale at the base,

then retighten the two hex nuts.

Tip: The first time you set the angle of the compound rest for cutting threads, mark the location on the cross slide as a quick refer- ence point. This will allow you to quickly return the compound rest to that exact angle the next time you need to cut threads.

Model G0740 (Mfg. Since 11/12)

Figure 62. Example of tool mounted in tool post.

2.5x 0.5" = 1.25").

2.Firmly secure the cutting tool with at least two tool post bolts.

3.Check and adjust the cutting tool to the spindle centerline, as instructed in the next subsection.