Centers

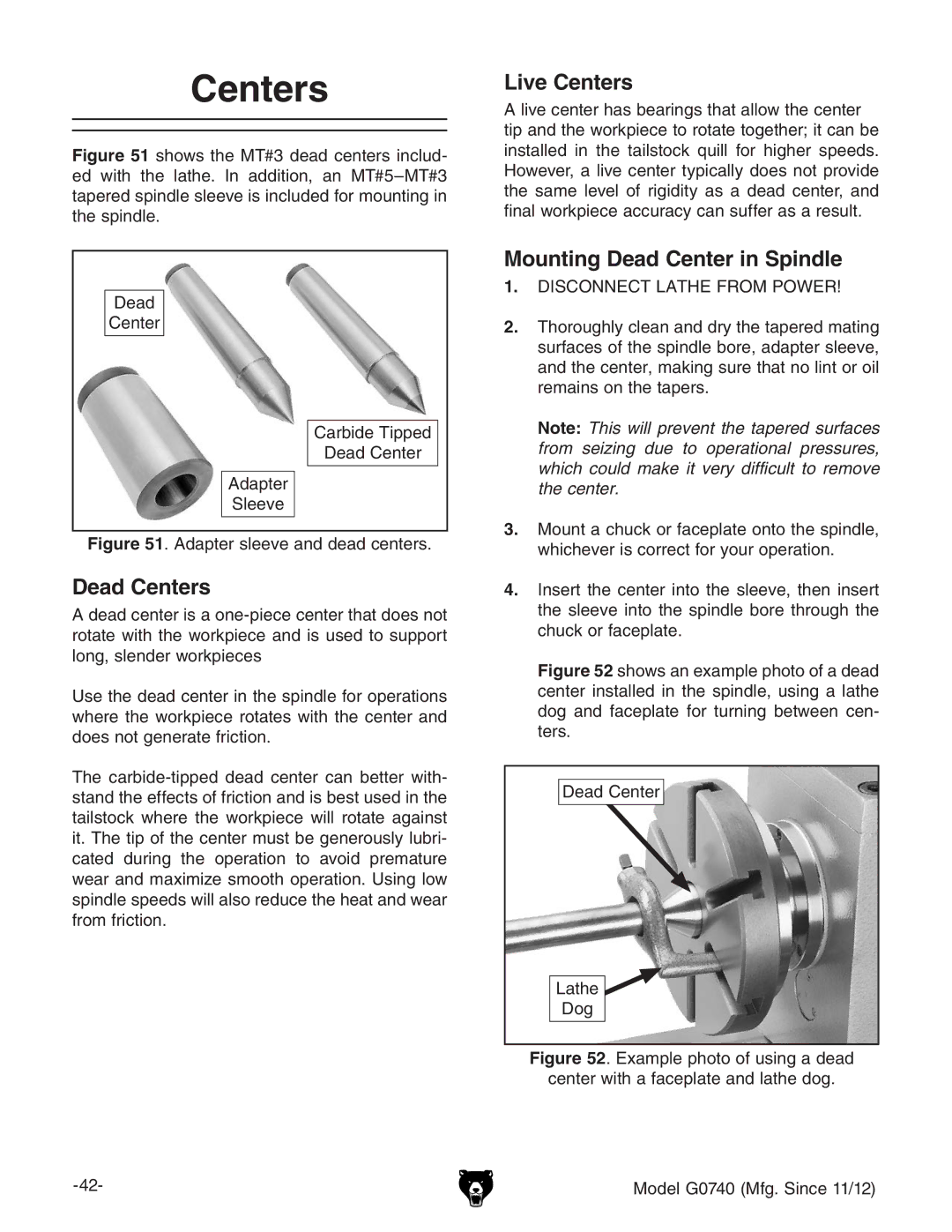

Figure 51 shows the MT#3 dead centers includ- ed with the lathe. In addition, an MT#5–MT#3 tapered spindle sleeve is included for mounting in the spindle.

Dead

Center

Carbide Tipped

Dead Center

Adapter

Sleeve

Figure 51. Adapter sleeve and dead centers.

Dead Centers

A dead center is a

Use the dead center in the spindle for operations where the workpiece rotates with the center and does not generate friction.

The

Live Centers

A live center has bearings that allow the center tip and the workpiece to rotate together; it can be installed in the tailstock quill for higher speeds. However, a live center typically does not provide the same level of rigidity as a dead center, and final workpiece accuracy can suffer as a result.

Mounting Dead Center in Spindle

1.DISCONNECT LATHE FROM POWER!

2.thoroughly clean and dry the tapered mating surfaces of the spindle bore, adapter sleeve, and the center, making sure that no lint or oil remains on the tapers.

Note: This will prevent the tapered surfaces from seizing due to operational pressures, which could make it very difficult to remove the center.

3.mount a chuck or faceplate onto the spindle, whichever is correct for your operation.

4.insert the center into the sleeve, then insert the sleeve into the spindle bore through the chuck or faceplate.