NOTE: Place a loose rag over the open vent port to pre- vent large amounts of liquid from being sprayed on the pump and adjacent equipment.

| Care should be exercised if you |

CAUTION | |

| are pumping hot water or chemi- |

| |

cals to avoid personal injury. | |

Install and torque the vent plug to the values provided in the “ENGINEERING DATA” sec- tion of this manual. Close the drain plug pin (1SV and 2SV only) and open the discharge valve.

For installations with the liquid level below the pump:

Install foot valve at suction end.

For models 1SV and 2SV only, it is necessary to fully unscrew the pin located in the drain plug. See figure on previous page.

With the provided plastic funnel, completely fill the casing with liquid.

Install and torque the vent plug, close the drain plug pin (1SV and 2SV only) and open the suc- tion valve.

4. Operation

Make sure that the drained liquid does not cause damage or injuries.

After stabilizing the system at normal operating conditions, check piping for correct alignments. If necessary, adjust pipe supports.

| HAZARDOUS MACHINERY. | |

WARNING | ||

| MOTOR THERMAL PROTEC- | |

Hazardous | ||

TORS CAN RESTART MOTOR | ||

machinery | ||

UNEXPECTEDLY AND WITH- | ||

| ||

| OUT WARNING, CAUSING | |

| SEVERE PERSONAL INJURY. |

See the “ENGINEERING DATA” section in this manual for the recommended maximum pump starts per hour.

| DISCONNECT AND LOCKOUT | |

WARNING | ||

| ELECTRICAL POWER BEFORE | |

Hazardous | ||

ATTEMPTING ANY MAINTE- | ||

voltage | ||

NANCE. FAILURE TO DO SO | ||

| ||

| CAN CAUSE SHOCK, BURNS OR | |

| DEATH. |

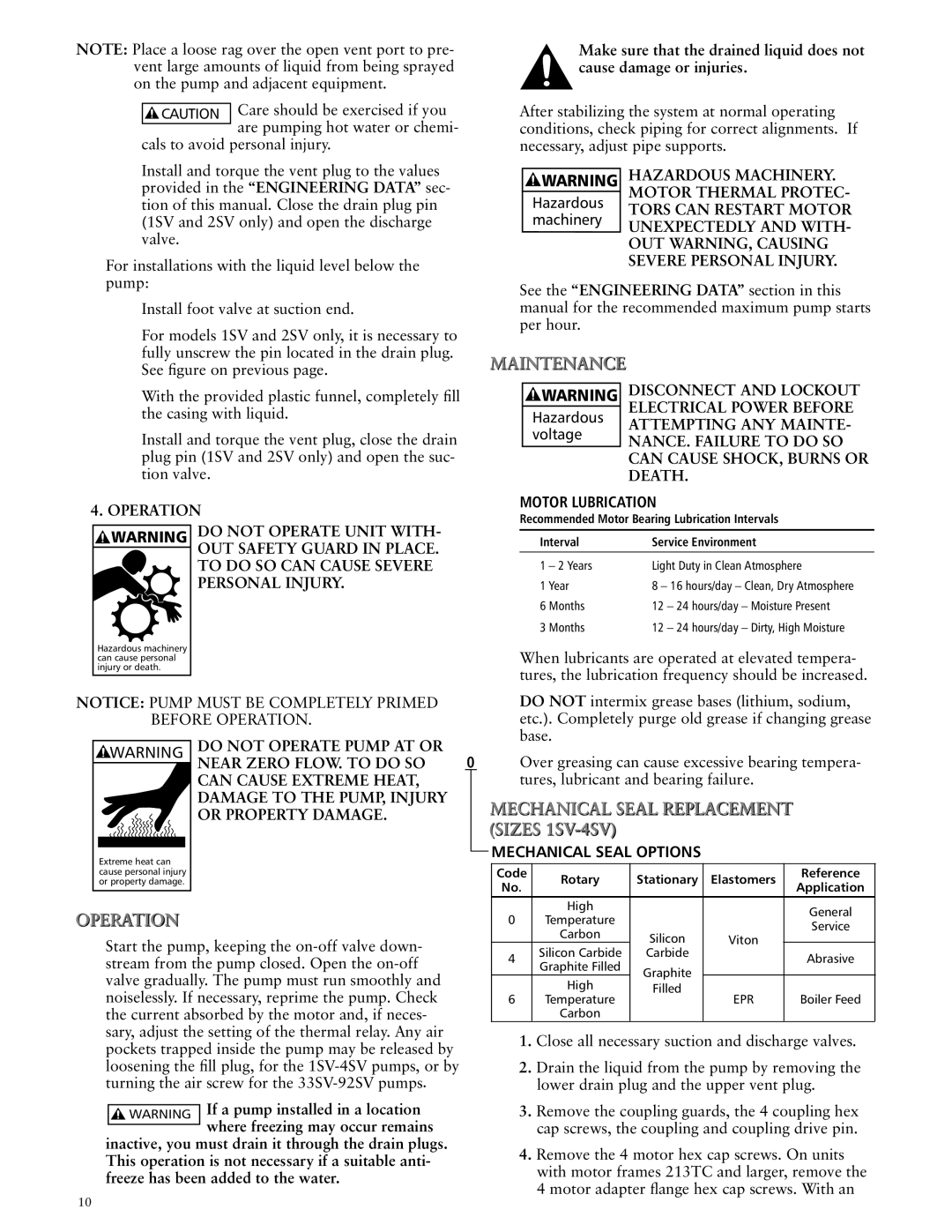

MOTOR LUBRICATION

Recommended Motor Bearing Lubrication Intervals

![]() WARNING

WARNING

Hazardous machinery can cause personal injury or death.

DO NOT OPERATE UNIT WITH- OUT SAFETY GUARD IN PLACE. TO DO SO CAN CAUSE SEVERE PERSONAL INJURY.

Interval | Service Environment | ||

|

|

| |

1 | – 2 Years | Light Duty in Clean Atmosphere | |

1 | Year | 8 – 16 hours/day – Clean, Dry Atmosphere | |

6 | Months | 12 | – 24 hours/day – Moisture Present |

3 | Months | 12 | – 24 hours/day – Dirty, High Moisture |

When lubricants are operated at elevated tempera- tures, the lubrication frequency should be increased.

NOTICE: PUMP MUST BE COMPLETELY PRIMED BEFORE OPERATION.

DO NOT intermix grease bases (lithium, sodium, etc.). Completely purge old grease if changing grease base.

![]() WARNING

WARNING

Extreme heat can cause personal injury or property damage.

DO NOT OPERATE PUMP AT OR

NEAR ZERO FLOW. TO DO SO 0 CAN CAUSE EXTREME HEAT, DAMAGE TO THE PUMP, INJURY OR PROPERTY DAMAGE.

Over greasing can cause excessive bearing tempera- tures, lubricant and bearing failure.

MECHANICAL SEAL OPTIONS

Code | Rotary | Stationary Elastomers | Reference | |

No. | Application | |||

|

| |||

| High |

| General | |

0 | Temperature |

| ||

| Service | |||

| Carbon |

|

Start the pump, keeping the

| If a pump installed in a location |

WARNING | |

| where freezing may occur remains |

|

inactive, you must drain it through the drain plugs. This operation is not necessary if a suitable anti- freeze has been added to the water.

|

|

| Silicon | Viton |

|

4 | Silicon Carbide |

| Carbide |

| Abrasive |

Graphite Filled |

| Graphite |

| ||

|

|

|

| ||

| High |

|

|

| |

6 |

| Filled | EPR | Boiler Feed | |

Temperature |

|

| |||

| Carbon |

|

|

|

|

1.Close all necessary suction and discharge valves.

2.Drain the liquid from the pump by removing the lower drain plug and the upper vent plug.

3.Remove the coupling guards, the 4 coupling hex cap screws, the coupling and coupling drive pin.

4.Remove the 4 motor hex cap screws. On units with motor frames 213TC and larger, remove the 4 motor adapter flange hex cap screws. With an

10