lubricant compatible with the

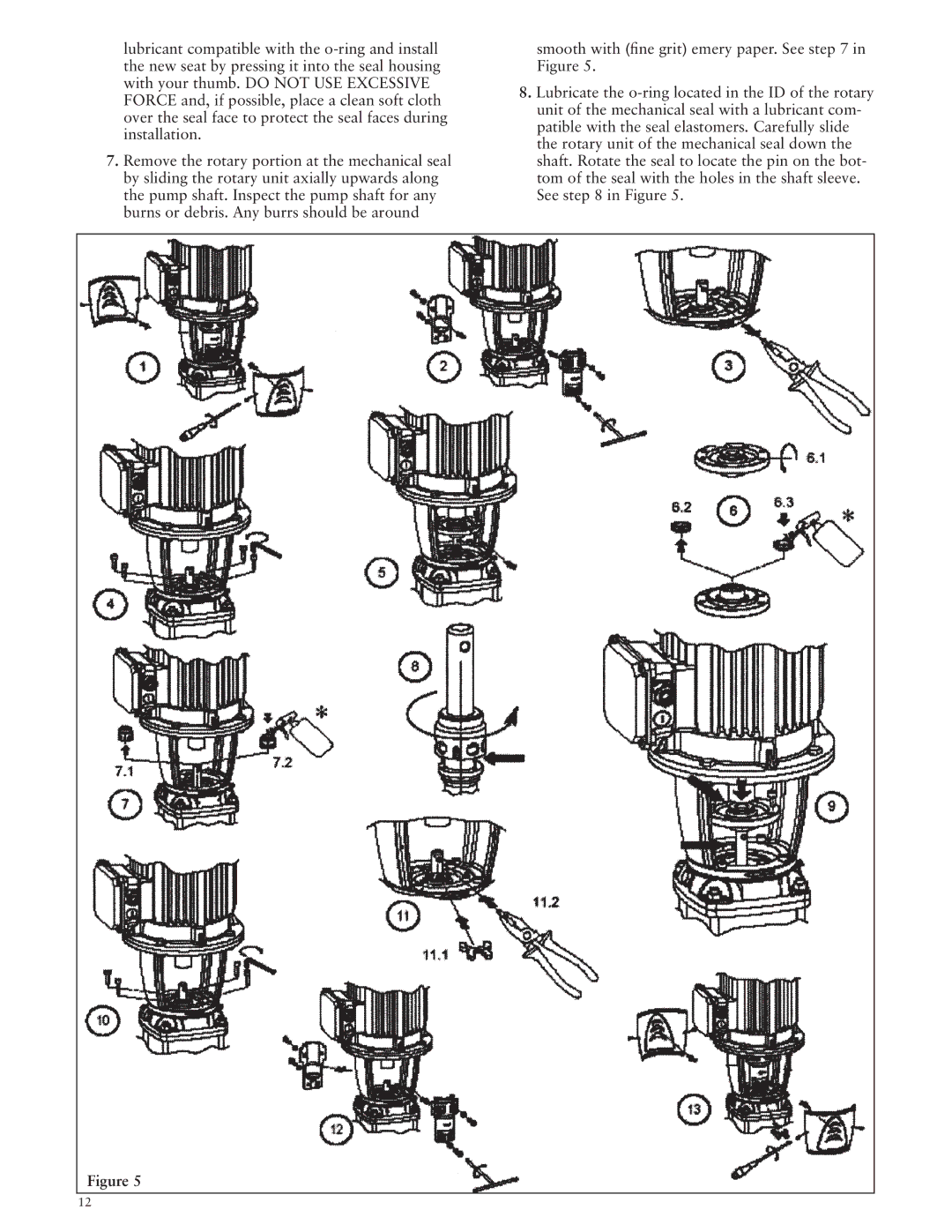

7.Remove the rotary portion at the mechanical seal by sliding the rotary unit axially upwards along the pump shaft. Inspect the pump shaft for any burns or debris. Any burrs should be around

smooth with (fine grit) emery paper. See step 7 in Figure 5.

8.Lubricate the

Figure 5

12