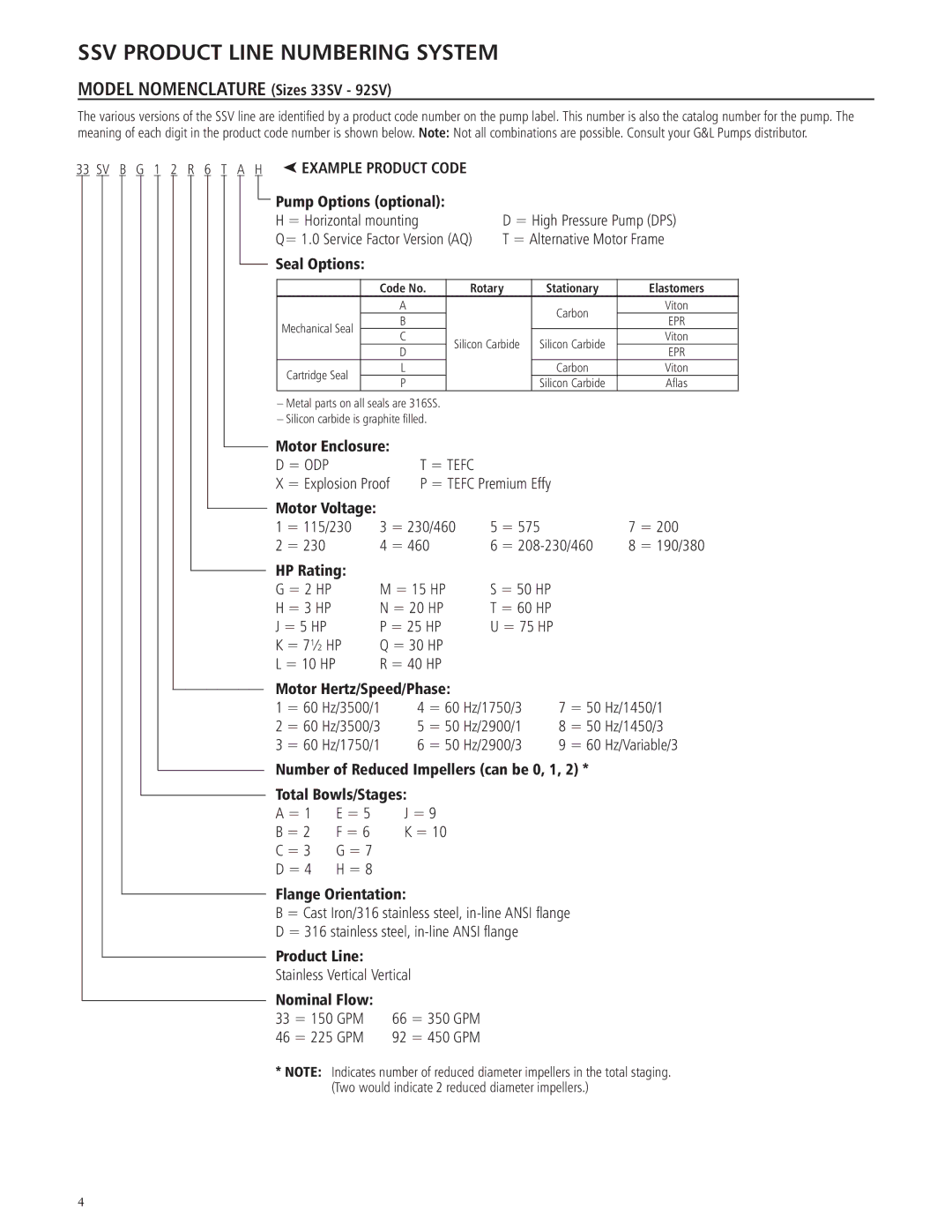

SSV PRODUCT LINE NUMBERING SYSTEM

MODEL NOMENCLATURE (Sizes 33SV - 92SV)

The various versions of the SSV line are identified by a product code number on the pump label. This number is also the catalog number for the pump. The meaning of each digit in the product code number is shown below. Note: Not all combinations are possible. Consult your G&L Pumps distributor.

33 SV B G 1 2 R 6 T A H |

|

|

| ➤ EXAMPLE PRODUCT CODE |

|

|

|

| |||||||||||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Pump Options (optional): |

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| H = Horizontal mounting |

| D = High Pressure Pump (DPS) | ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Q= 1.0 Service Factor Version (AQ) | T = Alternative Motor Frame | |||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Seal Options: |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Code No. | Rotary | Stationary | Elastomers | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| A |

|

| Carbon | Viton |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Mechanical Seal |

| B |

|

| EPR |

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| C | Silicon Carbide | Silicon Carbide | Viton |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| D | EPR | ||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Cartridge Seal |

| L |

|

| Carbon | Viton |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| P |

|

| Silicon Carbide | Aflas | ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||

–Metal parts on all seals are 316SS.

–Silicon carbide is graphite filled.

Motor Enclosure: |

|

D = ODP | T = TEFC |

X = Explosion Proof | P = TEFC Premium Effy |

Motor Voltage: |

|

| |

1 | = 115/230 | 3 | = 230/460 |

2 | = 230 | 4 | = 460 |

HP Rating: |

|

| |

G = 2 HP | M = 15 HP | ||

H = 3 HP | N = 20 HP | ||

J = 5 HP | P = 25 HP | ||

K = 7½ HP | Q = 30 HP | ||

L = 10 HP | R = 40 HP | ||

5 | = 575 | 7 | = 200 |

6 | = | 8 | = 190/380 |

S = 50 HP

T = 60 HP

U = 75 HP

Motor Hertz/Speed/Phase: |

|

| ||

1 = 60 Hz/3500/1 | 4 = 60 Hz/1750/3 | 7 = 50 | Hz/1450/1 | |

2 = 60 Hz/3500/3 | 5 = 50 Hz/2900/1 | 8 = 50 | Hz/1450/3 | |

3 = 60 Hz/1750/1 | 6 = 50 Hz/2900/3 | 9 = 60 | Hz/Variable/3 | |

Number of Reduced Impellers (can be 0, 1, 2) * |

| |||

Total Bowls/Stages: |

|

| ||

A = 1 | E = 5 | J = 9 |

|

|

B = 2 | F = 6 | K = 10 |

|

|

C = 3 | G = 7 |

|

|

|

D = 4 | H = 8 |

|

|

|

Flange Orientation:

B = Cast Iron/316 stainless steel,

D = 316 stainless steel,

Product Line:

Stainless Vertical Vertical

Nominal Flow: |

|

33 = 150 GPM | 66 = 350 GPM |

46 = 225 GPM | 92 = 450 GPM |

*NOTE: Indicates number of reduced diameter impellers in the total staging. (Two would indicate 2 reduced diameter impellers.)