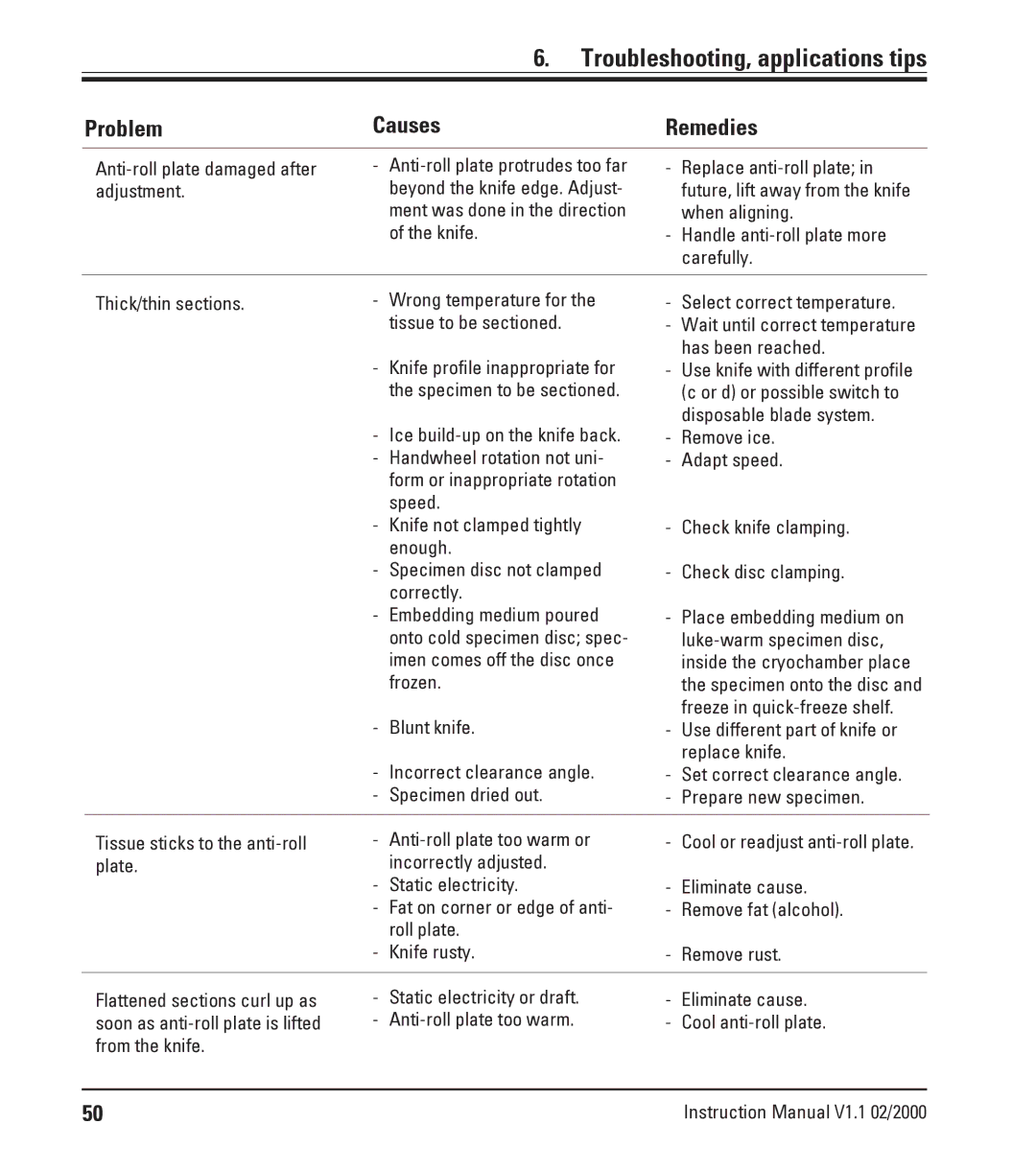

6. Troubleshooting, applications tips

Problem | Causes | Remedies |

-

-Replace

-Handle

Thick/thin sections. | - | Wrong temperature for the | - | Select correct temperature. |

|

| tissue to be sectioned. | - Wait until correct temperature | |

|

|

|

| has been reached. |

| - Knife profile inappropriate for | - Use knife with different profile | ||

|

| the specimen to be sectioned. |

| (c or d) or possible switch to |

|

|

|

| disposable blade system. |

| - Ice | - | Remove ice. | |

| - Handwheel rotation not uni- | - | Adapt speed. | |

|

| form or inappropriate rotation |

|

|

|

| speed. |

|

|

| - Knife not clamped tightly | - | Check knife clamping. | |

|

| enough. |

|

|

| - | Specimen disc not clamped | - | Check disc clamping. |

|

| correctly. |

|

|

| - Embedding medium poured | - Place embedding medium on | ||

|

| onto cold specimen disc; spec- |

|

|

|

| imen comes off the disc once |

| inside the cryochamber place |

|

| frozen. |

| the specimen onto the disc and |

|

|

|

| freeze in |

| - | Blunt knife. | - Use different part of knife or | |

|

|

|

| replace knife. |

| - | Incorrect clearance angle. | - Set correct clearance angle. | |

| - | Specimen dried out. | - | Prepare new specimen. |

|

|

|

|

|

Tissue sticks to the

-

-Static electricity.

-Fat on corner or edge of anti- roll plate.

-Knife rusty.

-Cool or readjust

-Eliminate cause.

-Remove fat (alcohol).

-Remove rust.

Flattened sections curl up as | - | Static electricity or draft. | - | Eliminate cause. |

soon as | - | - | Cool | |

from the knife. |

|

|

|

|

50 | Instruction Manual V1.1 02/2000 |