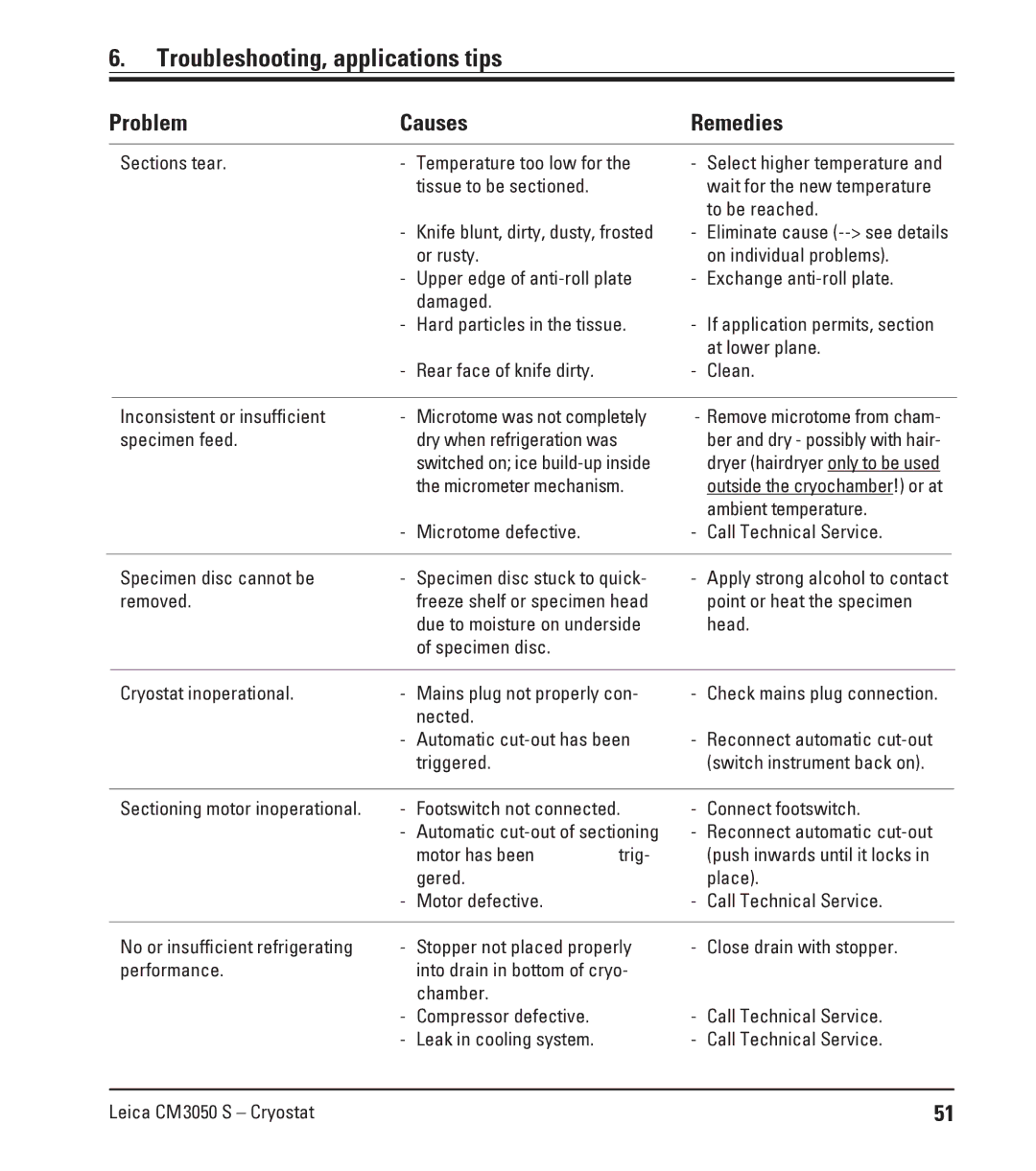

6.Troubleshooting, applications tips

Problem | Causes | Remedies | ||

|

|

|

|

|

Sections tear. | - | Temperature too low for the | - | Select higher temperature and |

|

| tissue to be sectioned. |

| wait for the new temperature |

|

|

|

| to be reached. |

| - Knife blunt, dirty, dusty, frosted | - Eliminate cause | ||

|

| or rusty. |

| on individual problems). |

| - Upper edge of | - | Exchange | |

|

| damaged. |

|

|

| - | Hard particles in the tissue. | - If application permits, section | |

|

|

|

| at lower plane. |

| - | Rear face of knife dirty. | - | Clean. |

Inconsistent or insufficient | - | Microtome was not completely |

specimen feed. |

| dry when refrigeration was |

|

| switched on; ice |

|

| the micrometer mechanism. |

| - | Microtome defective. |

- Remove microtome from cham- ber and dry - possibly with hair- dryer (hairdryer only to be used outside the cryochamber!) or at ambient temperature.

- Call Technical Service.

Specimen disc cannot be | - Specimen disc stuck to quick- |

removed. | freeze shelf or specimen head |

| due to moisture on underside |

| of specimen disc. |

-Apply strong alcohol to contact point or heat the specimen head.

Cryostat inoperational. | - | Mains plug not properly con- | - | Check mains plug connection. | |

|

| nected. |

|

|

|

| - | Automatic | - | Reconnect automatic | |

|

| triggered. |

|

| (switch instrument back on). |

|

|

|

|

| |

Sectioning motor inoperational. | - | Footswitch not connected. | - | Connect footswitch. | |

| - Automatic | - | Reconnect automatic | ||

|

| motor has been | trig- |

| (push inwards until it locks in |

|

| gered. |

|

| place). |

| - | Motor defective. |

| - | Call Technical Service. |

|

|

|

|

| |

No or insufficient refrigerating | - | Stopper not placed properly | - | Close drain with stopper. | |

performance. |

| into drain in bottom of cryo- |

|

| |

|

| chamber. |

|

|

|

| - | Compressor defective. |

| - | Call Technical Service. |

| - | Leak in cooling system. |

| - | Call Technical Service. |

Leica CM3050 S – Cryostat | 51 |