TROUBLE DIAGNOSIS

Items | Precautions |

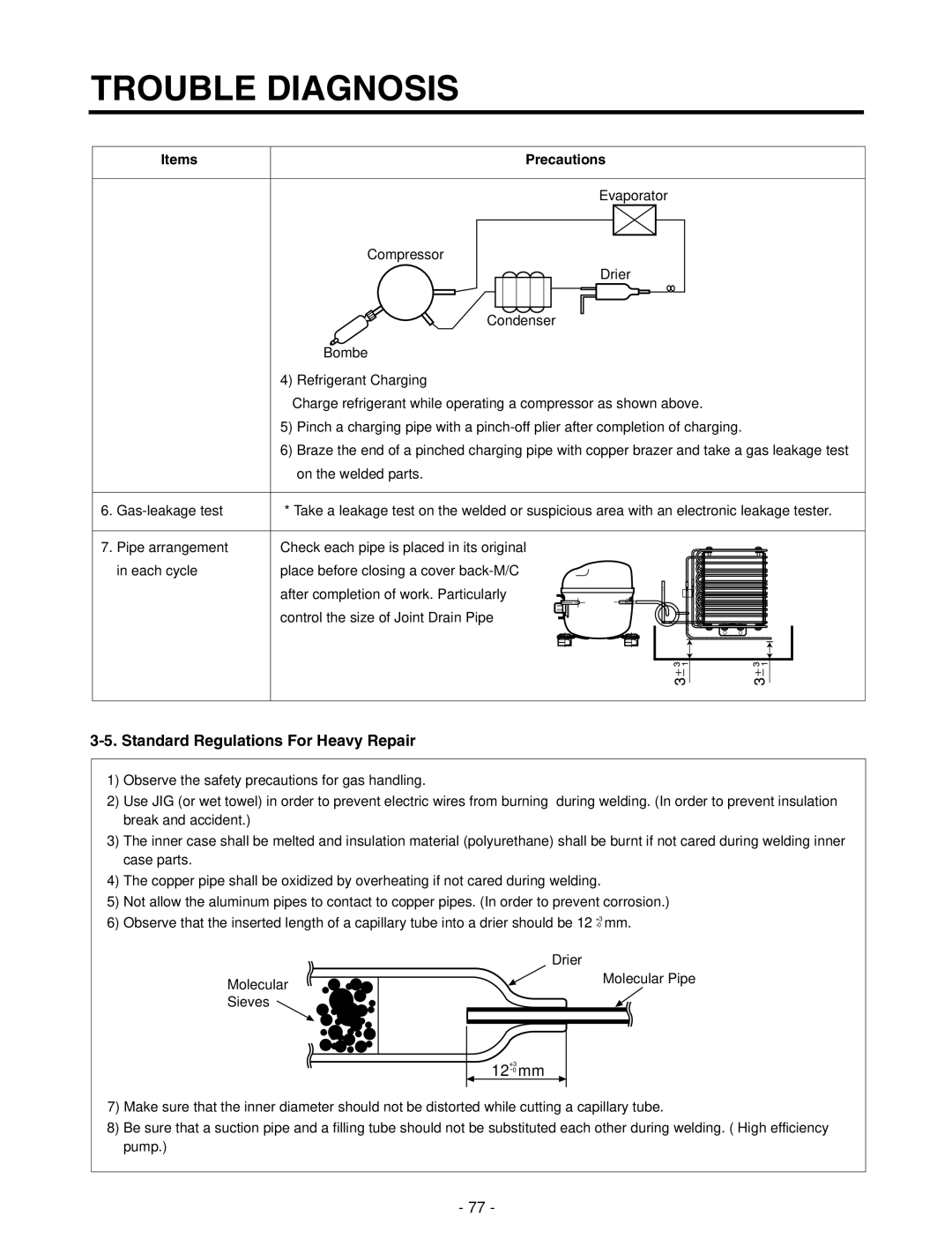

Evaporator

Compressor

Drier

Condenser

Bombe

4) Refrigerant Charging

Charge refrigerant while operating a compressor as shown above.

5)Pinch a charging pipe with a

6)Braze the end of a pinched charging pipe with copper brazer and take a gas leakage test on the welded parts.

6. | * Take a leakage test on the welded or suspicious area with an electronic leakage tester. | |

7. | Pipe arrangement | Check each pipe is placed in its original |

| in each cycle | place before closing a cover |

|

| after completion of work. Particularly |

|

| control the size of Joint Drain Pipe |

3-5. Standard Regulations For Heavy Repair

1) Observe the safety precautions for gas handling.

2) Use JIG (or wet towel) in order to prevent electric wires from burning during welding. (In order to prevent insulation break and accident.)

3) The inner case shall be melted and insulation material (polyurethane) shall be burnt if not cared during welding inner case parts.

4) The copper pipe shall be oxidized by overheating if not cared during welding.

5) Not allow the aluminum pipes to contact to copper pipes. (In order to prevent corrosion.)

6) Observe that the inserted length of a capillary tube into a drier should be 12 +3 mm.

| Drier |

Molecular | Molecular Pipe |

| |

Sieves |

|

+3

12-0 mm

7)Make sure that the inner diameter should not be distorted while cutting a capillary tube.

8)Be sure that a suction pipe and a filling tube should not be substituted each other during welding. ( High efficiency pump.)

- 77 -