- 63 -

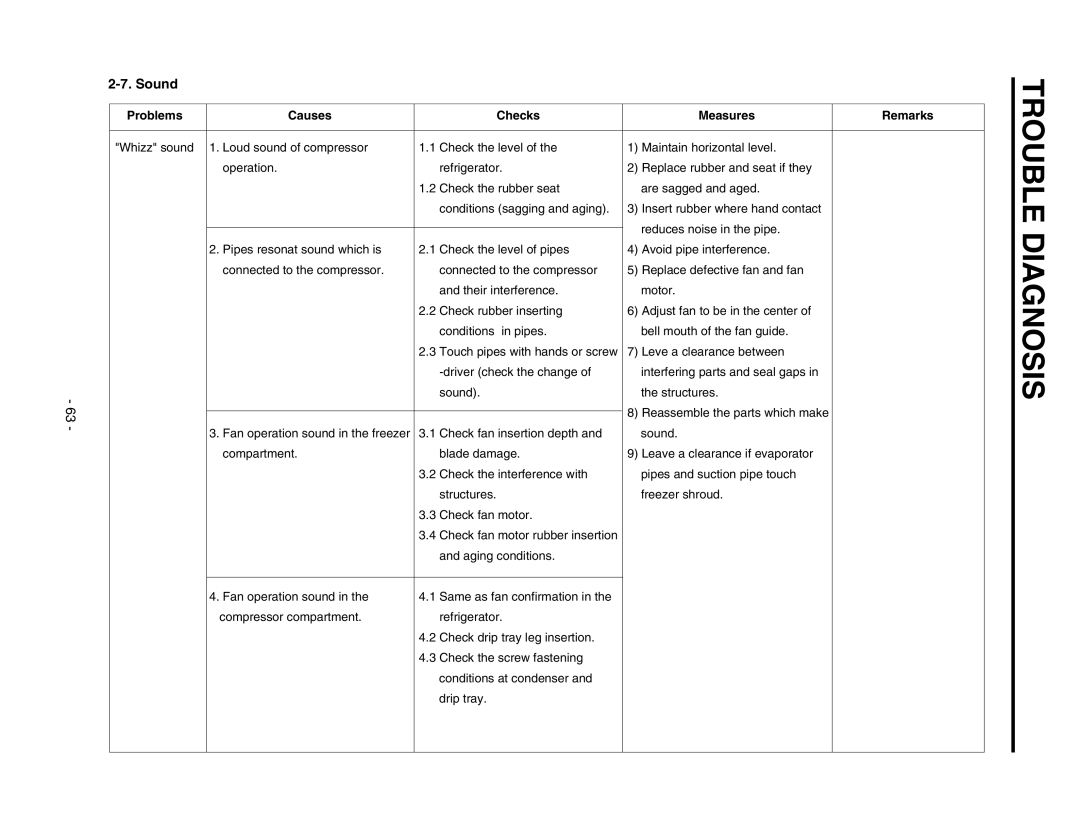

2-7. Sound

Problems | Causes |

| Checks |

| Measures | Remarks |

|

|

|

|

|

| |

"Whizz" sound | 1. Loud sound of compressor | 1.1 Check the level of the | 1) | Maintain horizontal level. |

| |

| operation. |

| refrigerator. | 2) | Replace rubber and seat if they |

|

|

| 1.2 | Check the rubber seat |

| are sagged and aged. |

|

|

|

| conditions (sagging and aging). | 3) | Insert rubber where hand contact |

|

|

|

|

|

| reduces noise in the pipe. |

|

|

|

|

|

|

| |

| 2. Pipes resonat sound which is | 2.1 Check the level of pipes | 4) | Avoid pipe interference. |

| |

| connected to the compressor. |

| connected to the compressor | 5) | Replace defective fan and fan |

|

|

|

| and their interference. |

| motor. |

|

|

| 2.2 | Check rubber inserting | 6) | Adjust fan to be in the center of |

|

|

|

| conditions in pipes. |

| bell mouth of the fan guide. |

|

|

| 2.3 | Touch pipes with hands or screw | 7) | Leve a clearance between |

|

|

|

|

| interfering parts and seal gaps in |

| |

|

|

| sound). |

| the structures. |

|

|

|

|

| 8) | Reassemble the parts which make |

|

|

|

|

|

| ||

| 3. Fan operation sound in the freezer | 3.1 Check fan insertion depth and |

| sound. |

| |

| compartment. |

| blade damage. | 9) | Leave a clearance if evaporator |

|

|

| 3.2 | Check the interference with |

| pipes and suction pipe touch |

|

|

|

| structures. |

| freezer shroud. |

|

|

| 3.3 | Check fan motor. |

|

|

|

|

| 3.4 | Check fan motor rubber insertion |

|

|

|

|

|

| and aging conditions. |

|

|

|

|

|

|

|

|

| |

| 4. Fan operation sound in the | 4.1 Same as fan confirmation in the |

|

|

| |

| compressor compartment. |

| refrigerator. |

|

|

|

|

| 4.2 | Check drip tray leg insertion. |

|

|

|

|

| 4.3 | Check the screw fastening |

|

|

|

|

|

| conditions at condenser and |

|

|

|

|

|

| drip tray. |

|

|

|

|

|

|

|

|

|

|