TROUBLE DIAGNOSIS

3-4. Practical Work For Heavy Repair

Items |

| Precautions |

|

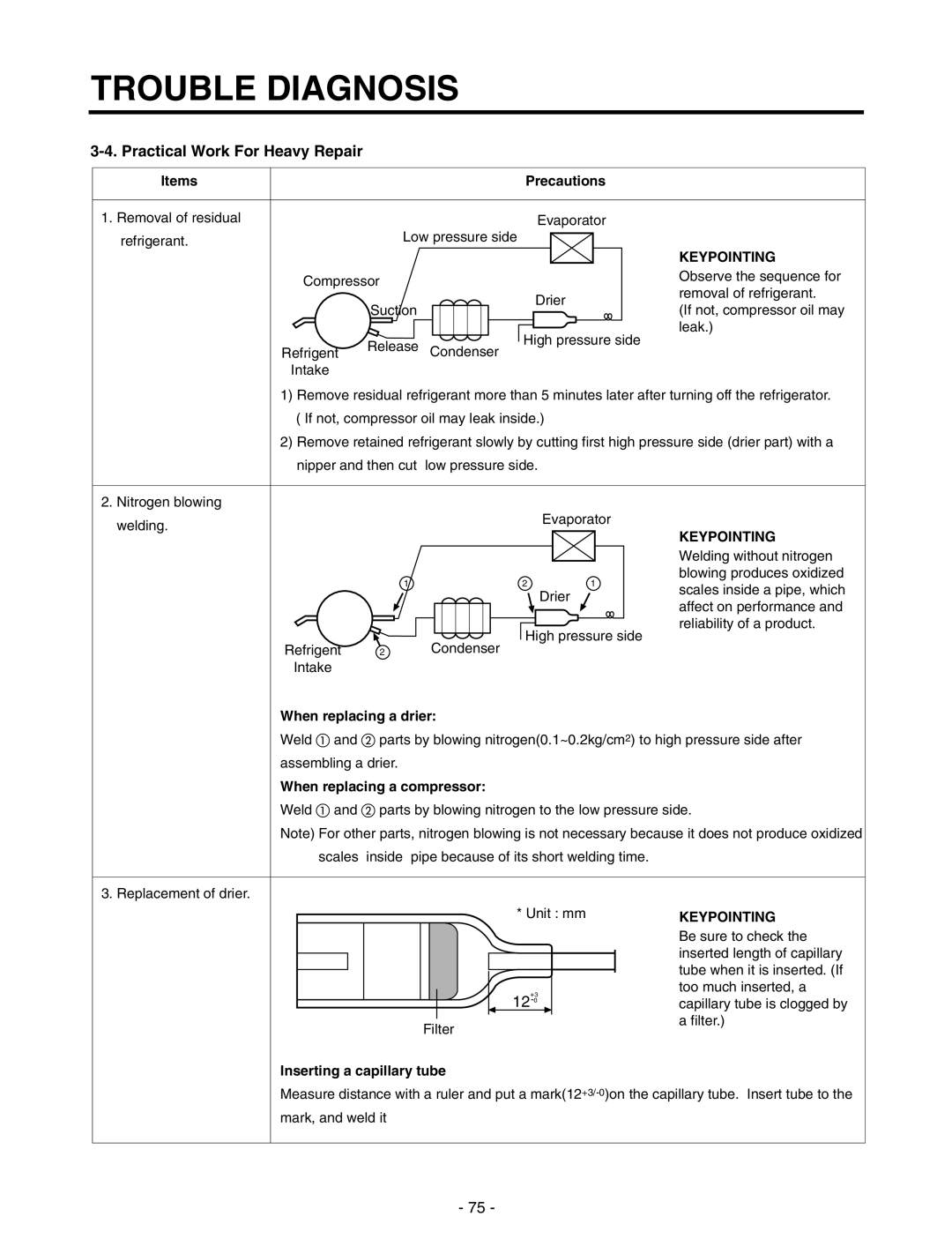

1. Removal of residual |

| Evaporator |

|

refrigerant. | Low pressure side |

| |

|

| KEYPOINTING | |

|

|

| |

Compressor |

| Observe the sequence for | |

| removal of refrigerant. | ||

|

| Drier | |

| Suction | (If not, compressor oil may | |

|

| ||

|

| High pressure side | leak.) |

Refrigent | Release |

| |

Condenser |

| ||

Intake |

|

|

|

1)Remove residual refrigerant more than 5 minutes later after turning off the refrigerator. ( If not, compressor oil may leak inside.)

2)Remove retained refrigerant slowly by cutting first high pressure side (drier part) with a nipper and then cut low pressure side.

2. Nitrogen blowing |

|

|

|

|

|

welding. |

|

|

| Evaporator |

|

|

|

|

| KEYPOINTING | |

|

|

|

|

| |

|

|

|

|

| Welding without nitrogen |

|

| 1 | 2 | 1 | blowing produces oxidized |

|

| scales inside a pipe, which | |||

|

|

|

| Drier | |

|

|

|

| affect on performance and | |

|

|

|

|

| |

|

|

| High pressure side | reliability of a product. | |

|

|

|

| ||

Refrigent | 2 | Condenser |

|

| |

Intake |

|

|

|

|

|

When replacing a drier: |

|

| |||

Weld | and | parts by blowing nitrogen(0.1~0.2kg/cm2) to high pressure side after | |||

assembling a drier. |

|

|

| ||

When replacing a compressor: |

|

| |||

Weld | and | parts by blowing nitrogen to the low pressure side. | |||

Note) For other parts, nitrogen blowing is not necessary because it does not produce oxidized

scales inside pipe because of its short welding time.

3. Replacement of drier.

|

|

|

| * Unit : mm |

| |||||

KEYPOINTING | ||||||||||

|

|

|

|

|

|

|

|

| Be sure to check the | |

|

|

|

|

|

|

|

|

| inserted length of capillary | |

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| tube when it is inserted. (If | |

|

|

|

|

|

|

|

|

| ||

|

|

| +3 |

|

|

| too much inserted, a | |||

|

|

|

|

|

| |||||

|

|

|

|

|

| capillary tube is clogged by | ||||

|

|

|

|

|

|

|

|

| a filter.) | |

Filter | ||||||||||

| ||||||||||

Inserting a capillary tube

Measure distance with a ruler and put a

mark, and weld it

- 75 -