|

|

| INSTALLATION |

|

|

| |||

|

|

|

|

|

|

|

|

|

|

|

|

|

| RECOMMENDED EQUIPMENT |

|

|

| ||

|

|

|

|

|

|

|

|

| |

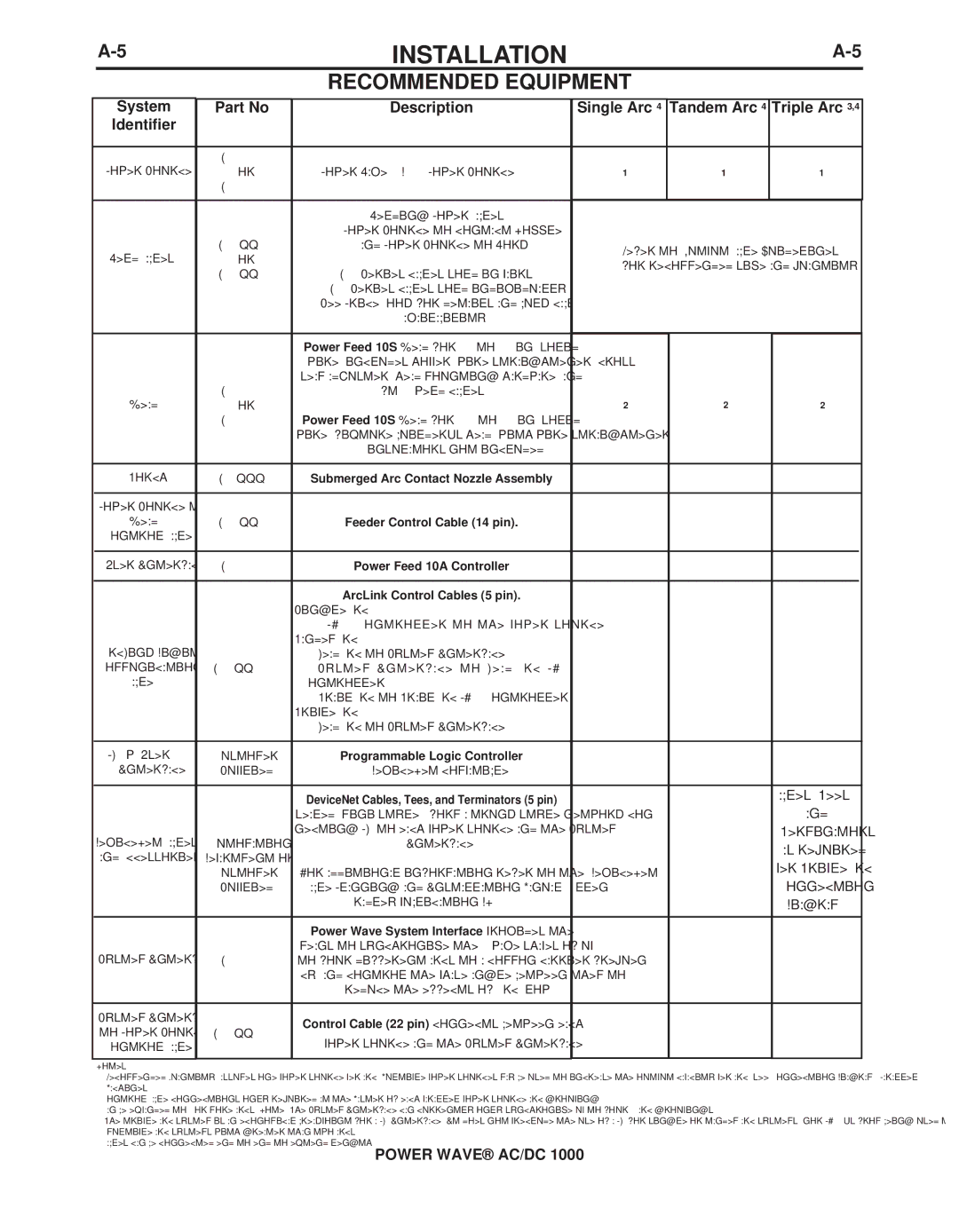

| System | Part No. | Description | Single Arc 4 | Tandem Arc 4 | Triple Arc 3,4 | |||

| Identifier |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

| Power Source |

|

|

|

|

|

| ||

| Power Wave AC/DC 1000 Power Source | 1 1 | 2 1 | 3 1 |

| ||||

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Welding Power Cables |

|

|

|

|

|

|

|

|

| Power Source to contact Nozzle, |

|

|

|

|

|

| Weld Cables | and Power Source to Work |

| Refer to "Output Cable Guidelines" | |||||

|

|

| |||||||

|

|

| for recommended size and quantity | ||||||

|

|

| K2163 Series cables sold in pairs. |

| |||||

|

|

|

|

|

|

|

| ||

|

|

|

| K1842 Series cables sold individually. |

|

|

|

|

|

|

|

|

| See Price Book for details and bulk cable |

|

|

|

|

|

|

|

|

| availability. |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| Power Feed 10S Head for 3/32 to 7/32 in. solid |

|

|

|

|

|

|

|

|

| wire (includes hopper, wire straightener, cross |

|

|

|

|

|

|

|

|

| seam adjuster, head mounting hardware, and 2 - |

|

|

|

|

|

| Head | 5ft 4/0 weld cables). |

|

|

|

|

| ||

| Power Feed 10S Head for 3/32 to 7/32 in. solid | 1 2 | 2 2 | 3 2 |

| ||||

|

|

|

|

|

|

|

| ||

|

|

|

| wire (fixture builder's head, with wire straightener - |

|

|

|

|

|

|

|

|

| insulators not included). |

|

|

|

|

|

|

|

|

|

|

|

|

| ||

| Torch | Submerged Arc Contact Nozzle Assembly | 1 | 2 | 3 |

| |||

|

|

|

|

|

|

|

|

| |

| Power Source to |

|

|

|

| 2 2 | 3 2 |

| |

| Head | Feeder Control Cable (14 pin). | 1 2 |

| |||||

| Control Cable |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| ||

| User Interface | Power Feed 10A Controller | 1 2,4 | 2 2,4 |

| ||||

|

|

|

| ArcLink Control Cables (5 pin). |

|

|

|

|

|

|

|

|

| Single Arc: |

|

|

|

|

|

|

|

|

| (1) |

|

|

|

|

|

| ArcLink Digital |

| Tandem Arc: |

|

|

|

|

| |

|

| (1) Lead Arc to System Interface | 1 | 3 | 1 |

| |||

| Communication | (2)System Interface to Lead Arc |

| ||||||

|

|

|

|

|

| ||||

| Cable |

| Controller |

|

|

|

|

| |

|

|

|

| (3) Trail Arc to Trail Arc |

|

|

|

|

|

|

|

|

| Triple Arc: |

|

|

|

|

|

|

|

|

| (1) Lead Arc to System Interface |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| PLC (w/ User | Customer | Programmable Logic Controller | 1 4 |

| ||||

| Interface) | Supplied | (DeviceNet compatible) |

| |||||

|

|

|

|

|

| ||||

|

|

|

|

|

|

|

|

| |

|

|

|

| DeviceNet Cables, Tees, and Terminators (5 pin) |

|

|

| Cables, Tees, | |

|

|

|

|

|

|

| and | ||

|

|

|

| sealed "mini style") form a trunk style network con- |

|

|

| ||

DeviceNet Cables | Automation | necting PLC to each power source and the System | Terminators | ||||||

Interface. | as required | ||||||||

| and Accessories | Department or |

|

|

|

| |||

|

|

|

|

| per Triple Arc | ||||

|

|

| Customer | For additional information refer to the "DeviceNet |

|

|

| ||

|

|

|

|

|

| Connection | |||

|

|

| Supplied | Cable Planning and Installation Manual" (Allen |

|

|

| ||

|

|

|

| Bradley publication |

|

|

| Diagram 4 | |

|

|

|

|

|

|

|

|

|

|

|

|

|

| Power Wave System Interface provides the |

|

|

|

|

|

| System Interface |

| means to synchronize the AC wave shapes of up | 1 2 | 1 2 |

| |||

| to four different arcs to a common carrier frequen- |

| |||||||

|

|

|

| cy, and control the phase angle between them to |

|

|

|

|

|

|

|

|

| reduce the effects of "Arc Blow". |

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

| System Interface |

| Control Cable (22 pin) connects between each | 2 2 | 3 2 |

| |||

| to Power Source |

| |||||||

| power source and the System Interface. |

|

|

|

|

| |||

| Control Cable |

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

Notes:

1."Recommended Quantity" assumes one power source per arc. Multiple power sources may be used to increase the output capacity per arc (see "Connection Diagram - Parallel Machines").

2.Control Cable connections only required at the Master of each parallel power source arc grouping.

3.Can be expanded to 4 or more arcs (Note: The System Interface can currently only synchronize up to four AC arc groupings).

4.The triple arc system is an economical breakpoint for a PLC Interface. It does not preclude the use of a PLC for single or tandem arc systems, nor

5.Cables can be connected end to end to extend length.

POWER WAVE® AC/DC 1000