| INSTALLATION |

|

|

|

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

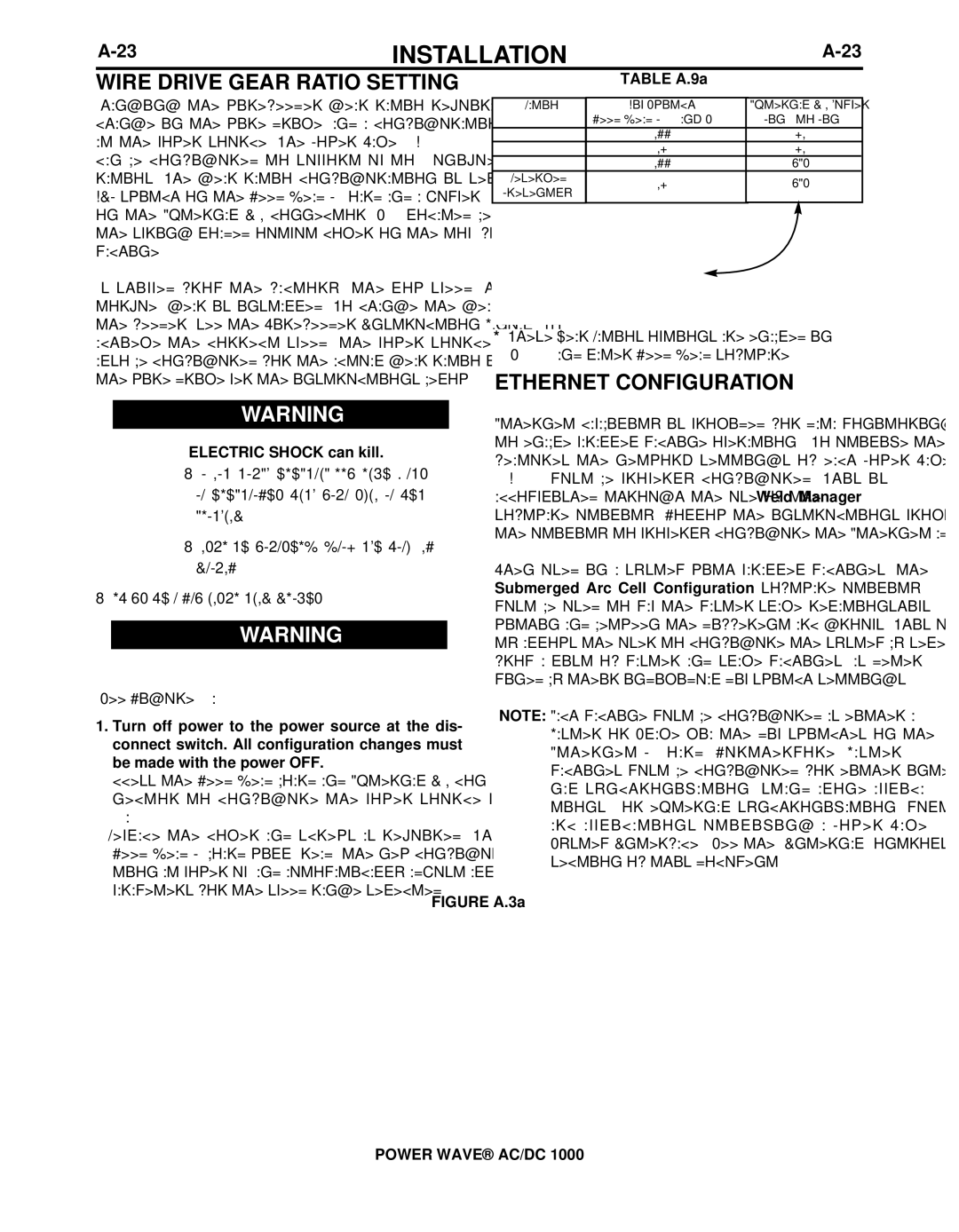

WIRE DRIVE GEAR RATIO SETTING |

|

|

|

|

|

|

|

|

| ||||||||||||

|

|

|

| TABLE A.9a |

|

| |||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

Changing the wirefeeder gear ratio requires a gear |

|

|

|

|

|

|

|

|

|

| |||||||||||

Ratio |

|

| Dip Switch #8 | External I/O Jumper | |||||||||||||||||

change in the wire drive, and a configuration change |

|

|

| (Feed Head PCB - Bank S1) | (Pin 5 to Pin 12) | ||||||||||||||||

142:1 |

|

|

|

|

|

|

| OFF |

|

| NO | ||||||||||

at the power source. The Power Wave AC/DC 1000 |

|

|

|

|

|

|

|

|

| ||||||||||||

95:1 |

|

|

|

|

|

|

| ON |

|

| NO | ||||||||||

can be configured to support up to 4 unique gear |

|

|

|

|

|

|

|

|

| ||||||||||||

57:1* |

|

|

|

|

|

|

| OFF |

|

| YES |

| |||||||||

ratios. The gear ratio configuration is selected via a | Reserved* |

|

|

|

|

| ON |

|

| YES | |||||||||||

DIP switch on the Feed Head PC Board and a jumper | (Presently57:1) |

|

|

|

|

|

|

| |||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

| |||||||||

on the External I/O connector (S7 - located beneath |

|

|

|

|

|

| JUMPER | PIN 5 |

|

| |||||||||||

JUMPER PIN 12 |

|

|

| ||||||||||||||||||

the spring loaded output cover on the top, front of the |

|

|

|

|

|

|

|

|

|

| |||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

machine). |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

As shipped from the factory, the low speed (high | 12 11 10 9 | 8 | 7 | 6 | 5 | 4 | 3 | 2 | 1 |

|

|

| |||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| ||||||

torque) gear is installed. To change the gear ratio of |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||||

the feeder, see the Wirefeeder Instruction Manual. To | * These Gear Ratios options are enabled in | ||||||||||||||||||||

achieve the correct speed, the power source must | |||||||||||||||||||||

also be configured for the actual gear ratio installed in | |||||||||||||||||||||

ETHERNET CONFIGURATION | |||||||||||||||||||||

the wire drive per the instructions below: | |||||||||||||||||||||

|

|

| WARNING | Ethernet capability is provided for data monitoring, or | |||||||||||||||||

|

|

|

|

| |||||||||||||||||

|

|

| ELECTRIC SHOCK can kill. | to enable parallel machine operation. To utilize these | |||||||||||||||||

|

|

| features the network settings of each Power Wave | ||||||||||||||||||

|

|

| • Do not touch electrically live parts | ||||||||||||||||||

|

|

| AC/DC 1000 must be properly configured. This is | ||||||||||||||||||

|

|

| or electrodes with your skin or wet | ||||||||||||||||||

|

|

| accomplished through the use of the Weld Manager | ||||||||||||||||||

|

|

| clothing. | software utility. Follow the instructions provided with | |||||||||||||||||

|

|

| • Insulate yourself from the work and | the utility to properly configure the Ethernet address. | |||||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |||

|

|

| ground. | When used in a system with parallel machines, the | |||||||||||||||||

• Always wear dry insulating gloves. | Submerged Arc Cell Configuration software utility | ||||||||||||||||||||

must be used to map the master/slave relationships | |||||||||||||||||||||

|

|

|

|

| |||||||||||||||||

|

|

|

|

| within and between the different arc groups. This utili- | ||||||||||||||||

|

|

| WARNING |

| |||||||||||||||||

|

|

|

| ty allows the user to configure the system by selecting | |||||||||||||||||

from a list of master and slave machines (as deter- | ||

mined by their individual dip switch settings). | ||

| ||

(See Figure A.3a) | NOTE: Each machine must be configured as either a | |

1. Turn off power to the power source at the dis- | ||

Master or Slave via the dip switches on the | ||

connect switch. All configuration changes must | ||

Ethernet PC Board. Furthermore, Master | ||

be made with the power OFF. | ||

machines must be configured for either inter- | ||

2. Access the Feed Head board and External I/O con- | ||

nal synchronization (stand alone applica- | ||

nector to configure the power source per table | ||

tions), or external synchronization (multiple | ||

A.9a. | ||

arc applications utilizing a Power Wave | ||

3. Replace the cover and screws as required. The | ||

System Interface). See the "Internal Controls" | ||

Feed Head PC board will "read" the new configura- | ||

section of this document. | ||

tion at power up, and automatically adjust all control | ||

|

parameters for the speed range selected.

FIGURE A.3a

S1EXTERNAL I/O

CONNECTOR

FEEDHEAD

P.C. BOARD

POWER WAVE® AC/DC 1000