INSTALLATION | ||

|

|

|

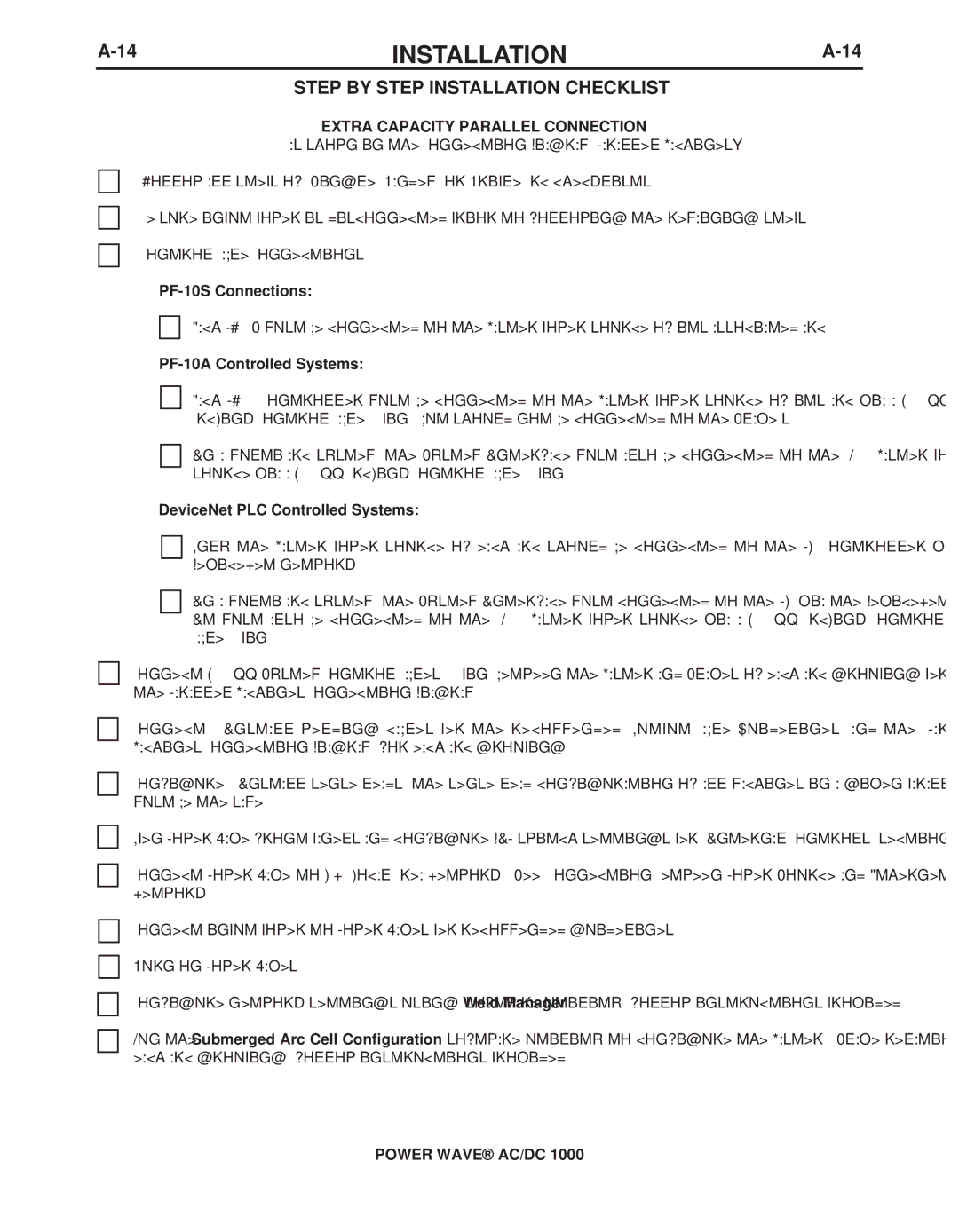

| STEP BY STEP INSTALLATION CHECKLIST |

|

EXTRA CAPACITY PARALLEL CONNECTION (as shown in the Connection Diagram "Parallel Machines”)

Follow all steps of Single, Tandem, or Triple Arc checklists.

Be sure input power is disconnected prior to following the remaining steps.

Control Cable Connections:

PF-10S Connections:

Each

PF-10A Controlled Systems:

Each

In a

DeviceNet PLC Controlled Systems:

Only the Master power source of each arc should be connected to the PLC Controller via the DeviceNet network.

In a

Connect

Connect / Install welding cables per the recommended "Output Cable Guidelines" and the "Parallel Machines Connection Diagram" for each arc grouping.

Configure / Install sense leads (the sense lead configuration of all machines in a given parallel arc grouping must be the same).

Open Power Wave front panels and configure DIP switch settings per "Internal Controls" section.

Connect Power Wave to LAN (Local Area Network). See "Connection Between Power Source and Ethernet Network."

Connect input power to Power Waves per recommended guidelines.

Turn on Power Waves.

Configure network settings using Weld Manager software utility (follow instructions provided).

Run the Submerged Arc Cell Configuration software utility to configure the Master / Slave relationships of each arc grouping (follow instructions provided).

POWER WAVE® AC/DC 1000