TROUBLESHOOTING | ||

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

|

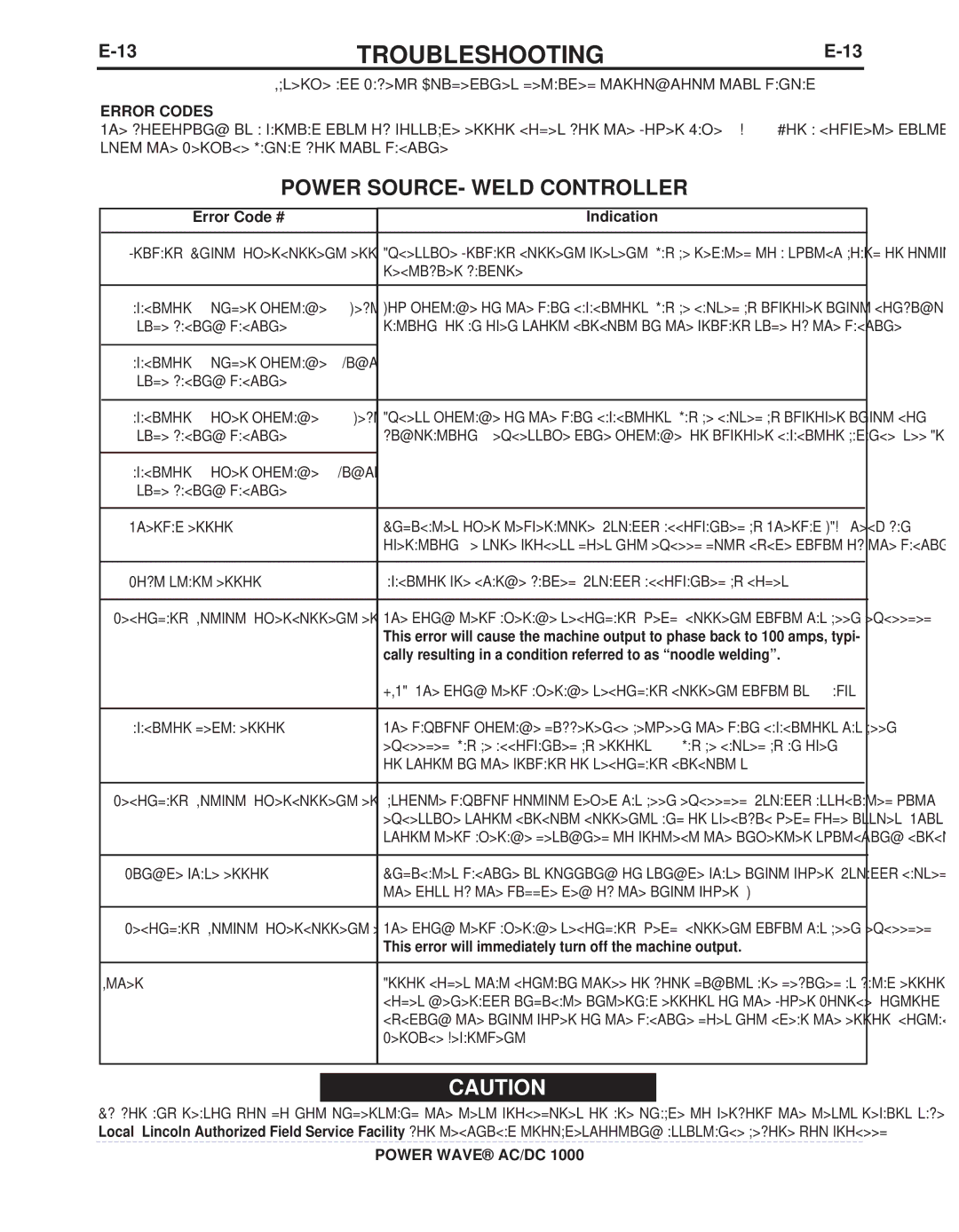

ERROR CODES

The following is a partial list of possible error codes for the Power Wave AC/DC 1000. For a complete listing con- sult the Service Manual for this machine.

POWER SOURCE- WELD CONTROLLER

|

| Error Code # | Indication |

|

|

|

|

31 | Primary (Input) overcurrent error. | Excessive Primary current present. May be related to a switch board or output | |

|

|

| rectifier failure. |

|

|

|

|

32 | Capacitor "A" under voltage (Left | Low voltage on the main capacitors. May be caused by improper input configu- | |

|

| side facing machine) | ration, or an open/short circuit in the primary side of the machine. |

33Capacitor "B" under voltage (Right side facing machine)

34 | Capacitor "A" over voltage | (Left | Excess voltage on the main capacitors. May be caused by improper input con- | |

| side facing machine) |

| figuration, , excessive line voltage, or improper capacitor balance (see Error | |

|

|

| 43) |

|

35 | Capacitor "B" over voltage | (Right |

| |

|

| |||

| side facing machine) |

|

|

|

|

|

|

|

|

36 | Thermal error |

| Indicates over temperature. Usually accompanied by Thermal LED. Check fan | |

|

|

| operation. Be sure process does not exceed duty cycle limit of the machine. | |

|

|

|

|

|

37 | Soft start error |

| Capacitor | |

|

|

| ||

41 Secondary (Output) overcurrent error | The long term average secondary (weld) current limit has been exceeded. | |||

|

|

| This error will cause the machine output to phase back to 100 amps, typi- | |

|

|

| cally resulting in a condition referred to as “noodle welding”. | |

|

|

| NOTE: The long term average secondary current limit is 1050 amps. | |

|

|

|

|

|

43 | Capacitor delta error |

| The maximum voltage difference between the main capacitors has been | |

|

|

| exceeded. May be accompanied by errors | |

|

|

| or short in the primary or secondary circuit(s). | |

|

|

| ||

46 Secondary (Output) overcurrent error | Absolute maximum output level has been exceeded. Usually associated with | |||

|

|

| excessive short circuit currents and/or specific weld mode issues. This is a | |

|

|

| short term average designed to protect the inverter switching circuitry. | |

|

|

|

|

|

49 | Single phase error |

| Indicates machine is running on single phase input power. Usually caused by | |

|

|

| the loss of the middle leg of the input power (L2). | |

54Secondary (Output) overcurrent error The long term average secondary (weld) current limit has been exceeded.

This error will immediately turn off the machine output.

Other | Error codes that contain three or four digits are defined as fatal errors. These |

| codes generally indicate internal errors on the Power Source Control Board. If |

| cycling the input power on the machine does not clear the error, contact the |

| Service Department. |

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER WAVE® AC/DC 1000