| TROUBLESHOOTING |

|

|

| |||

|

|

|

|

|

|

|

|

|

| Observe all Safety Guidelines detailed throughout this manual |

| ||||

|

|

|

|

|

|

|

|

|

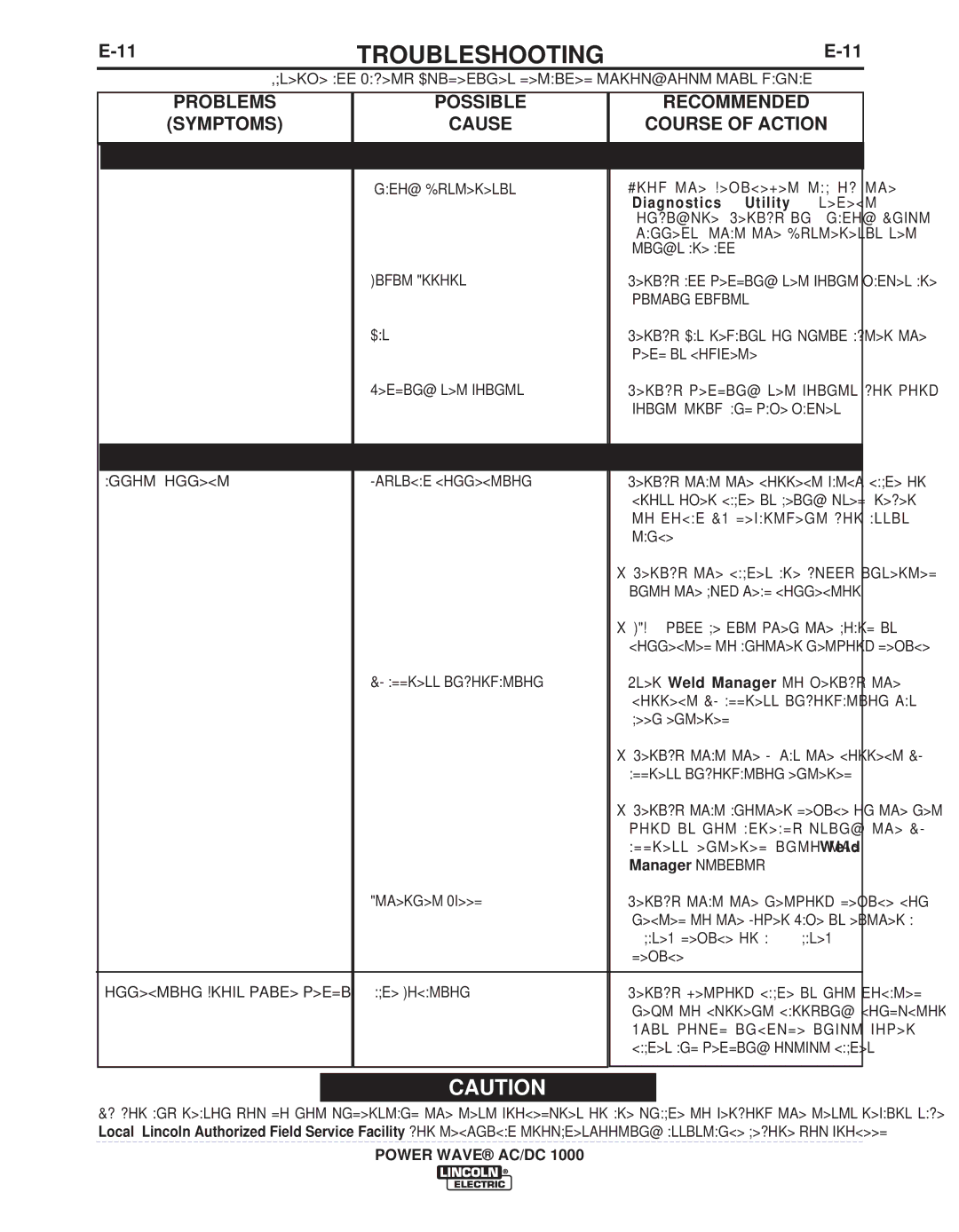

| PROBLEMS | POSSIBLE |

|

| RECOMMENDED |

|

|

| (SYMPTOMS) | CAUSE |

|

| COURSE OF ACTION | |

|

|

|

|

|

|

| |

|

|

|

| ||||

|

|

| 3. Analog Hysteresis. |

| 3. From the DeviceNet tab | of the | |

|

|

|

|

|

| Diagnostics Utility, | select |

|

|

|

|

|

| Configure. Verify in "Analog Input | |

|

|

|

|

|

| Channels" that the Hysteresis set- | |

|

|

|

|

|

| tings are all 0. |

|

|

|

| 4. Limit Errors. |

| 4. Verify all welding set point values are | ||

|

|

|

|

|

| within limits. |

|

|

|

| 5. Gas. |

| 5. Verify Gas remains on until after the | ||

|

|

|

|

|

| weld is complete. |

|

|

|

| 6. Welding set points. |

| 6. Verify welding set points for work | ||

|

|

|

|

|

| point, trim, and wave values. |

|

|

|

|

|

|

|

|

|

|

|

| ETHERNET |

|

|

|

|

Cannot Connect. | 1. Physical connection. |

| 1. Verify that the correct patch cable or | ||||

|

|

|

|

|

| cross over cable is being used (refer | |

|

|

|

|

|

| to local IT department for assis- | |

|

|

|

|

|

| tance). |

|

|

|

|

|

| • Verify the cables are fully inserted | ||

|

|

|

|

|

| into the bulk head connector. |

|

|

|

|

|

| • LED 10 will be lit when the board is | ||

|

|

|

|

|

| connected to another network device. | |

|

|

| 2. IP address information. |

| 2. User Weld Manager to verify the | ||

|

|

|

|

|

| correct IP address information has | |

|

|

|

|

|

| been entered. |

|

|

|

|

|

| • | Verify that the PC has the correct IP | |

|

|

|

|

|

| address information entered. |

|

|

|

|

|

| • | Verify that another device on the net- | |

|

|

|

|

|

| work is not already using the IP | |

|

|

|

|

|

| address entered into the Weld | |

|

|

|

|

|

| Manager utility. |

|

|

|

| 3. Ethernet Speed. |

| 3. Verify that the network device con- | ||

|

|

|

|

|

| nected to the Power Wave is either a | |

|

|

|

|

|

| ||

|

|

|

|

|

| device. |

|

|

|

|

|

| |||

Connection Drops while welding. | 1. Cable Location. |

| 1. Verify Network cable is not located | ||||

|

|

|

|

|

| next to current carrying conductors. | |

|

|

|

|

|

| This would include input power | |

|

|

|

|

|

| cables and welding output cables. | |

|

|

|

|

|

|

|

|

![]()

![]() CAUTION

CAUTION

If for any reason you do not understand the test procedures or are unable to perform the tests/repairs safely, contact your Local Lincoln Authorized Field Service Facility for technical troubleshooting assistance before you proceed.

POWER WAVE® AC/DC 1000