INSTALLATION | ||

|

|

|

EXTERNAL I/O CONNECTOR

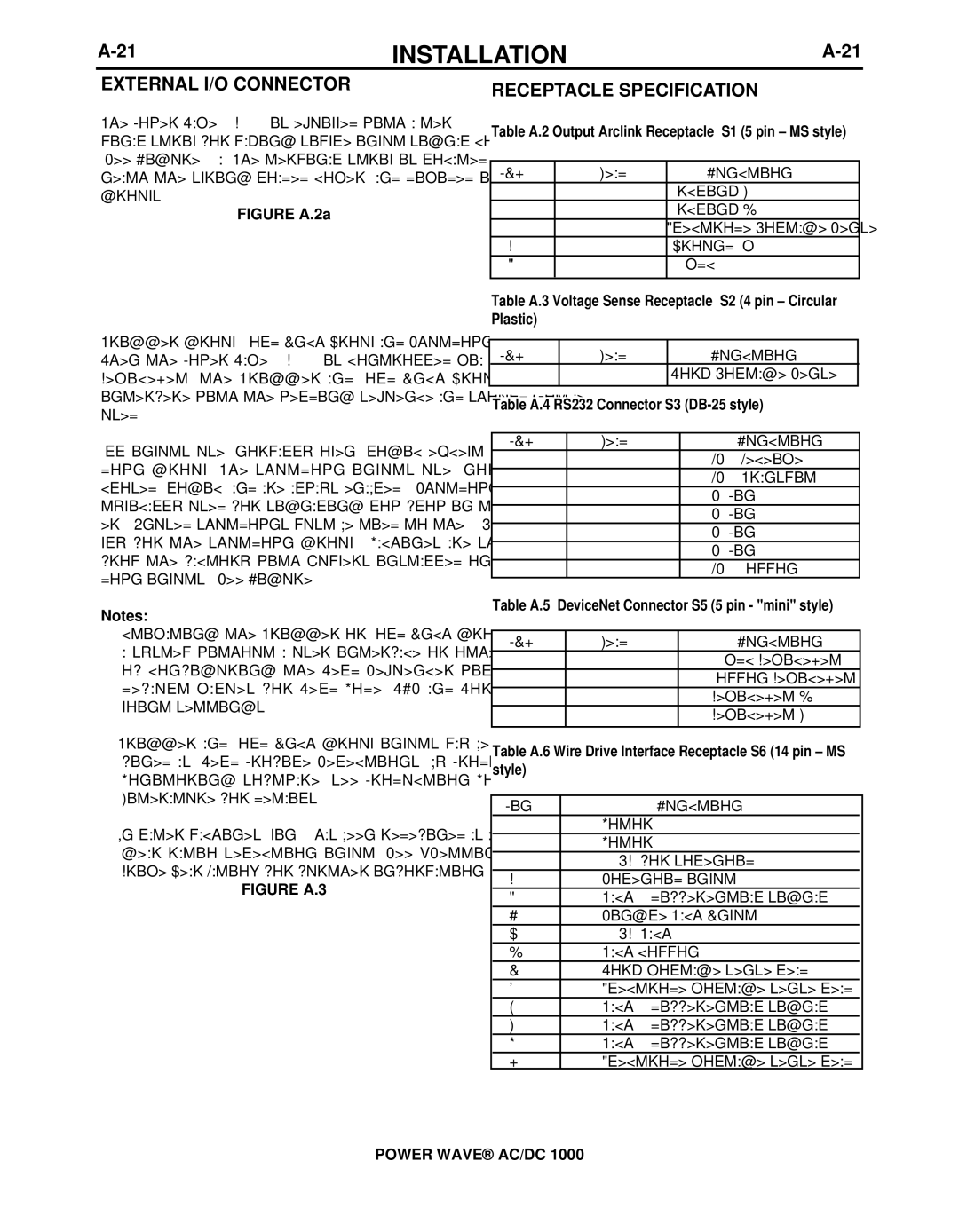

The Power Wave AC/DC 1000 is equipped with a ter- minal strip for making simple input signal connections. (See Figure A.2a) The terminal strip is located under- neath the

FIGURE A.2a

12 11 10 9 8 7 6 5 4 3 2 1

Trigger group, Cold Inch Group and Shutdown Group. When the Power Wave AC/DC 1000 is controlled via DeviceNet, the Trigger and Cold Inch Groups can interfere with the welding sequence and should not be used.

All inputs use "normally open" logic except the shut- down group. The shutdown inputs use "normally closed" logic, and are always enabled. Shutdown2 is typically used for signaling low flow in the water cool- er. Unused shutdowns must be tied to the +15V sup- ply for the shutdown group. Machines are shipped from the factory with jumpers installed on both shut- down inputs. (See Figure A.3)

Notes:

1.Activating the Trigger or Cold Inch group inputs on a system without a user interface or other means of configuring the Weld Sequencer will result in default values for Weld Mode, WFS and Work point settings.

2.Trigger and Cold Inch group inputs may be rede- fined as "Weld Profile Selections" by Production Monitoring software (see Production Monitoring Literature for details)

3.On later machines, pin 12 has been redefined as a gear ratio selection input. See “Setting the Wire Drive Gear Ratio” for further information.

FIGURE A.3

+15 VDC for Trigger Group | Trigger Input | Dual Procedure Input | 4 Step Input | +15 VDC for Cold Inch Group | Cold Inch Forward | Cold Inch Reverse | Gas Purge Input | +15 for shutdown group | Shutdown1 input | Shutdown2 input (Water Fault) | Reserved for future use |

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 |

| A |

|

|

| D |

|

|

| G |

|

|

|

| B |

|

|

| E |

|

|

| H |

|

|

|

| C |

|

|

| F |

|

|

| I |

RECEPTACLE SPECIFICATION

Table A.2 Output Arclink Receptacle S1 (5 pin – MS style)

PIN | Lead # | Function |

A | 53 | Arclink L |

B | 54 | Arclink H |

C | 67A | Electrode Voltage Sense |

D | 52 | Ground(0v) |

E | 51 | +40vdc |

|

|

|

Table A.3 Voltage Sense Receptacle S2 (4 pin – Circular Plastic)

| PIN |

| Lead # |

| Function | |

3 |

| 21A |

| Work Voltage Sense | ||

|

|

|

|

|

| |

| Table A.4 RS232 Connector S3 | |||||

|

|

|

|

|

|

|

| PIN |

| Lead # |

|

| Function |

| 2 |

| 253 |

| RS232 Receive | |

| 3 |

| 254 |

| RS232 Transmit | |

| 4 |

| # |

| S3 | Pin5 |

| 5 |

| # |

| S3 | Pin4 |

| 6 |

| ## |

| S3 | Pin20 |

| 20 |

| ## |

| S3 | Pin6 |

| 7 |

| 251 |

| RS232 Common | |

Table A.5 DeviceNet Connector S5 (5 pin - "mini" style)

PIN | Lead # | Function |

2 | 894 | +24vdc DeviceNet |

3 | 893 | Common DeviceNet |

4 | 892 | DeviceNet H |

5 | 891 | DeviceNet L |

|

|

|

Table A.6 Wire Drive Interface Receptacle S6 (14 pin – MS style)

Pin | Function |

|

A | Motor "+" |

|

B | Motor |

|

C | +40 VDC for solenoid |

|

D | Solenoid input |

|

E | Tach 2A differential signal |

|

F | Single Tach Input |

|

G | +15 VDC Tach |

|

H | Tach common |

|

I | Work voltage sense lead 21 |

|

J | Electrode voltage sense lead 67 |

|

K | Tach 1A differential signal |

|

L | Tach 1B differential signal |

|

M | Tach 2B differential signal |

|

N | Electrode voltage sense lead 67 |

|

POWER WAVE® AC/DC 1000