9403 9825 9850

Monarch Printers

Trademarks

Canadian D.O.C. Warning

Getting Started

TA B L E O F C O N T E N T S

Page

Iii

Printing

Status Polling

Page

Vii

Viii

O u t T h i s M a n u a l

T T I N G S TA R T E D

E a t i n g a n M P C L I I F o r m a t P a c k e t

F o r e Yo u B e g i n

2Getting Started

Type the following bar code data

Type the following constant text field

Type the following bar code field

Type the following text field

Sample Batch Packet

I l y S t a r t u p P r o c e d u r e s

A r t i n g w i t h a D e s i g n

T e r m i n i n g t h e P r i n t a r e a

T e r m i n i n g F o r m a t C o n t e n t s

A w i n g R o u g h S k e t c h e s

I n g S u p p l y L a y o u t G r i d s

N s i d e r i n g F o n t s

N s i d e r i n g F i e l d Ty p e s

I n g t h e F o r m a t Wo r k s h e e t

T e r c h a n g i n g P a c k e t s

L l i n g i n t h e F o r m a t Wo r k s h e e t

N F I G U R I N G T H E P R I N T E R

I n g P a r a l l e l C o m m u n i c a t i o n s

T t i n g C o m m u n i c a t i o n P a r a m e t e r s

‘comment‘

I n g M P C L I I C o n v e n t i o n s

C L I I P u n c t u a t i o n

A n d a r d S y n t a x G u i d e l i n e s

Page

N f i g u r a t i o n P a c k e t H e a d e r

I n g O n l i n e C o n f i g u r a t i o n Pa c k e t s

Header,ID#,action,device p

6Configuring the Printer

Header Constant ID# ID. Use

Units Optional parameter. Options English Metric Dots

Action Add configuration

A,N,E p

25,0,0,0 p

N f i g u r a t i o n S y n t a x G u i d e l i n e s

K i n g P r i n t a d j u s t m e n t s

A1. a System Setup Packet

F i n i n g t h e S y s t e m S e t u p Pa c k e t

Example I,A,0,0,1,1,0 p

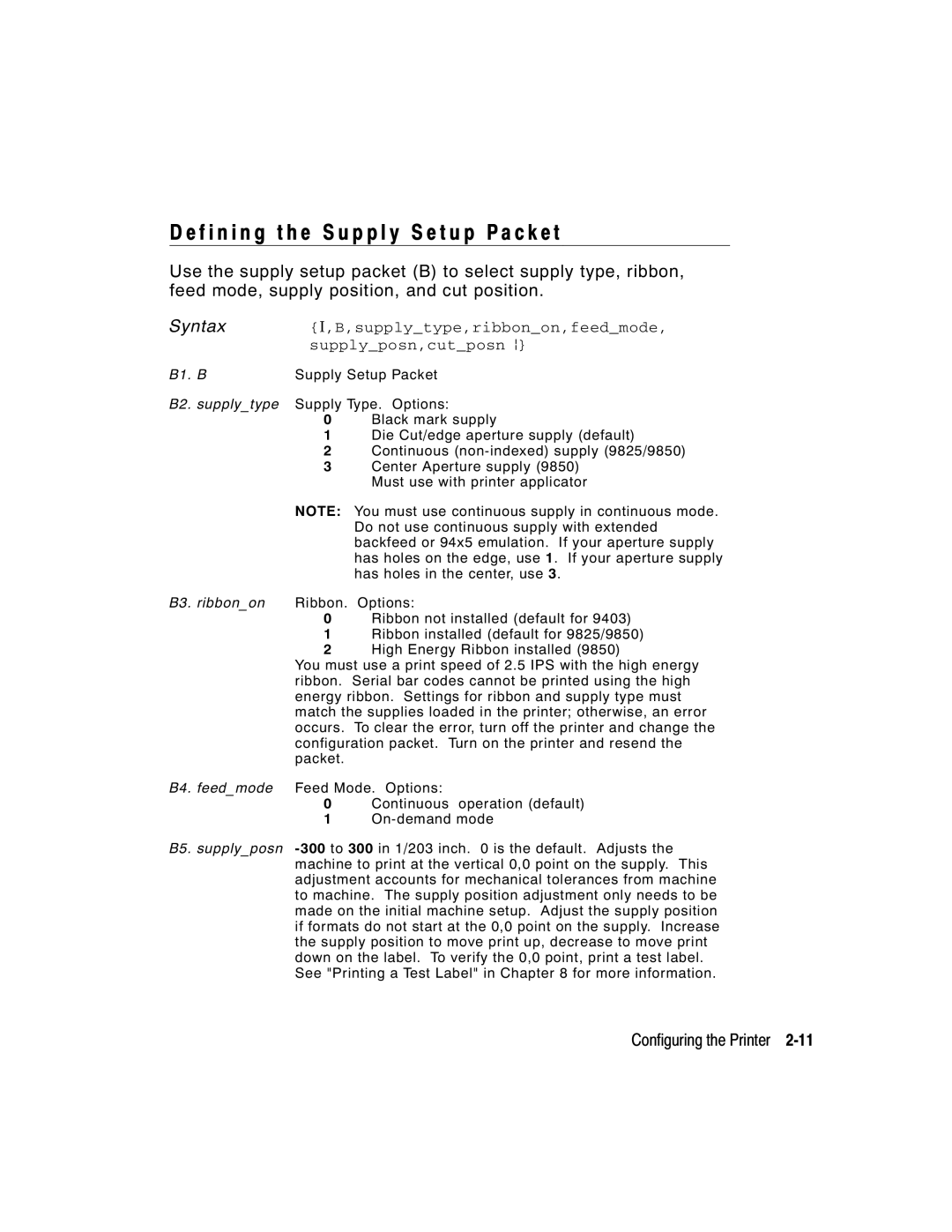

F i n i n g t h e S u p p l y S e t u p Pa c k e t

B1. B Supply Setup Packet

B3. ribbonon

Speedadj,phwidth p

12Configuring the Printer

Contrast,printadj,marginadjust

F i n i n g t h e P r i n t C o n t r o l P a c k e t

D1. D Monetary Formatting Packet

1,1,2 p

ANSIcd,string1,string2 p

?E?~123~044~034~124~125~126~094 p

S e t t i n g C o n t r o l C h a r a c t e r s

Syntax I,F,baud,wordlength,stopbits,parity, flowcontrol p

F i n i n g t h e B a c k f e e d C o n t r o l Pa c k e t

DTR default

F6. flowcontrol Flow Control. Options None

2 p

Action,dispos,bkfddis p

Page

Buffer,device,buffersize p

M1. M Memory Configuration Packet M2. buffer Buffer type

To reallocate in K Enter this amount

M3. device Storage type

22Configuring the Printer

Buffer Type 9403 9825 9850

9403 9825 9850

E c k i n g C u r r e n t B u f f e r S i z e s

O u t M e m o r y B u f f e r s

24Configuring the Printer

Linecount x 50/1024

F f e r a l l o c a t i o n C o n s i d e r a t i o n s

F f e r Wo r k s h e e t

Make copies of this page to use as a buffer worksheet

Page

A b l i n g I m m e d i a t e C o m m a n d s

I n g I m m e d i a t e C o m m a n d s

N d i n g I m m e d i a t e C o m m a n d s

FF1

Command Parameter

DD or

DCd

E a r i n g P a c k e t s f r o m M e m o r y

Font#,action,device p

I n g t h e F o n t Pa c k e t

Clears Format #1 from volatile RAM

C,R p

W4. device

W3. action Action. Options

Cell Height

Printer returns the following to the host

Cell Width

Spacing

Type

Baseline

H p

I n g t h e F l a s h U p l o a d Pa c k e t

Action Enter H to upload flash information

A s h C o n s i d e r a t i o n s

36Configuring the Printer

H,Z p

L o a d i n g F o r m a t H e a d e r I n f o r m a t i o n

Selects all formats in memory and returns the following

Header,format#,action,device p

Selects format1 and returns the following to the host

F I N I N G F I E L D S

Width,name p

F i n i n g t h e F o r m a t H e a d e r

Format Header begins a format file

Format#,action,device,measure,length

T1. T T2. field# T3. # of char T4. fix/var T5. row

F i n i n g Te x t F i e l d s

4Defining Fields

Line field Line field not Blocked out by

T12. alignment

6Defining Fields

Example T,2,10,V,250,50,0,1,1,1,B,C,0,0,0 p

8Defining Fields

Internal symbol set is used

F i n i n g B a r code F i e l d s

Each bar code field requires a separate definition

Bar Code Number of Characters Fixed or Variable

Left/Center/Right-Justified Fields Balanced Fields

Printer Unit of Measure Row or Column or End Row End Column

10Defining Fields

Postnet

B7. font Bar code. Options

Dots/mils Available

3 D P I B a r code D e n s i t i e s

12Defining Fields

Set

Data Appearance Char Set

Bar code Density Narrow Narrow to Data Appearance Char Set

Selector Or cpi Element Wide Ratio

Bar code Density Element Row Height

Row x Col Selector Length Code

14Defining Fields

Num Alphanum

Bar Code Size Density Max. Data App

0 D P I B a r code D e n s i t i e s

Row Height Aspect Data Appearance Char Set

16Defining Fields

Selector Or cpi Element Wide Ratio Length

Bar code Density

Num Alphanum

18Defining Fields

F i n i n g N o n P r i n t a b l e Te x t F i e l d s

20 p

F i n i n g C o n s t a n t Te x t F i e l d s

Field Data Field Type

Field#,# of char p

15 pt. CG Triumvirate

C1. C

C2. row

11 pt. CG Triumvirate

C8. color

22Defining Fields

C6. hgt mag

C7. wid mag

Defining Fields

Example C,30,10,0,1,1,1,B,L,0,0,MADE in USA,0 p

End col,thickness,pattern p

F i n i n g L i n e F i e l d s

N e Ty p e s

Type,row,column,angle/end row,length

L6. length/ If Using Segments end col

L5. angle/ If Using Segments end row

26Defining Fields

F i n i n g B o x F i e l d s

Q1. Q

28Defining Fields

Q2. row

Example Q,240,30,270,150,3, p

30Defining Fields

F I N I N G F I E L D O P T I O N S

2Defining Field Options

P l y i n g F i e l d O p t i o n s

M b i n i n g F i e l d O p t i o n s

S t r i c t i o n s

Fixed char p

T i o n 1 F i x e d D a t a

%$ p

Charcode p

T i o n 2 D a t a Ty p e R e s t r i c t i o n s

R1. R Option Header

Code,chars p

T i o n 3 D a t a E n t r y Te m p l a t e s

Start,copy code p

T i o n 4 C o p y D a t a

6Defining Field Options

Src fld,src start,# to copy,dest

R7. copy code Copy Method

R g i n g F i e l d s

203 Non-printable 339 Text

2033398BLUE Bar Code Defining Field Options

8Defining Field Options

T i o n 5 D e f i n e D a t a E n t r y S o u r c e s

B F i e l d s

Allows data to be entered from the keypad

20,Order Number p

T i o n 2 0 D e f i n e D a t a E n t r y P r o m p t s

T i o n 3 0 P a d d i n g D a t a

20,prompt p

10Defining Field Options

T i o n 3 1 C a l c u l a t e C h e c k D i g i t

M p l e U s e f o r P a d d i n g

Pads data with an X on the left side of the field

42,appearance code p

T i o n 4 2 P r i c e F i e l d

42,1 p

Widespace p

T i o n 5 0 B a r code D e n s i t y

12Defining Field Options

50,narrow,wide,gap,narspace

51,2,S p

51,security,stand/default p

Indicates Option

T i o n 5 2 P D F 4 1 7 W i d t h / L e n g t h

52,row/column,dimension p

14Defining Field Options

60,I,5,1,6 p

60,I/D,amount,l pos,r pos p

T i o n 6 1 R e i m a g e F i e l d

Check Digit Header

Fldlength,D/P,weights p

I n g C h e c k D i g i t s

Selector,action,device,modulus

1,2,3,4

M o f P r o d u c t s C a l c u l a t i o n

18Defining Field Options

20 + 2 + 6 + 6 + 16 + 5 + 4 + 3 + 36 =

M o f D i g i t s C a l c u l a t i o n

20Defining Field Options

+ 0 + 2 + 6 + 6 + 1 + 6 + 5 + 4 + 3 + 3 + 6 =

E AT I N G G R a P H I C S

E r v i e w o f C o m p l i a n c e L a b e l s

Run Length

E r v i e w o f B i t m a p p e d I m a g e s

T e r m i n i n g a M e t h o d

Hex Method

S i g n i n g B i t m a p p e d I m a g e s

S i g n i n g C o m p l i a n c e L a b e l s

E c i a l C o n s i d e r a t i o n s

Limit

I n g t h e H e x M e t h o d

Exceeds

Inches

6Creating Graphics

Assign 1 to every black square and 0 to every white square

I n g t h e R u n L e n g t h E n c o d i n g M e t h o d

Row 1, position 50 26 on

I n g F l a s h

T e r m i n i n g H o w t o S t o r e t h e I m a g e

I n g Vo l a t i l e R a M

I n g N o n v o l a t i l e R a M

I n g Te m p o r a r y S t o r a g e

S i t i o n i n g t h e G r a p h i c I m a g e

E a t i n g a G r a p h i c Pa c k e t

T h i n t h e G r a p h i c P a c k e t H e a d e r

T h i n t h e F i e l d

T h i n a F o r m a t

F i n i n g t h e G r a p h i c H e a d e r

G1. G Graphic Header

G5. units

99,A,R,G,0,0,0,99Wire p

G6. row

B4. algorithm

E a t i n g B i t m a p F i e l d s

B2. row

B3. column

Adjdir,adjamt,algorithm,data p

E a t i n g N e x t B i t m a p F i e l d s

1,2 p

E a t i n g D u p l i c a t e F i e l d s

Adjdir,adjamt,count p

117,24,H,03FFFFFFFFFFFFFFFFFFFC p

Sample compliance graphic packet is shown below

M p l e C o m p l i a n c e G r a p h i c P a c k e t

M p l e H e x G r a p h i c P a c k e t

20Creating Graphics

M p l e R u n L e n g t h G r a p h i c P a c k e t

Creating Graphics

GraphID,row,col,mode,rotation p

A c i n g t h e G r a p h i c i n a F o r m a t

F i n i n g t h e G r a p h i c F i e l d

22Creating Graphics

G4. column

G5. mode

M p l e C o m p l i a n c e L a b e l

G3. row

24Creating Graphics

M p l e B i t m a p G r a p h i c I m a g e

26Creating Graphics

I N T I N G

Page

Batch data

F i n i n g t h e B a t c h H e a d e r

Batch header

Batch control

4Printing

F i n i n g t h e B a t c h C o n t r o l F i e l d

E1. E Batch Control Field

1,4,2,1,4 p

F i n i n g B a t c h D a t a F i e l d s

N,1 p Decimal Character What Prints

R g e d o r S u b F i e l d s

C r e m e n t i n g F i e l d s

Sample Batch Data with Special Characters

Print Printhead Minimum Bar Code Narrow

Print Printing Printhead Knife Peel Mode Speed Density

W n l o a d i n g M e t h o d s

Q u e n t i a l M e t h o d

T c h Q u a n t i t y Z e r o M e t h o d

T c h M e t h o d

T i o n a l E n t r y M e t h o d

D i f y i n g F o r m a t s

TAT U S P O L L I N G

Q u i r y R e s p o n s e

Q u i r y R e q u e s t E N Q

Indicates the printer is offline 2Status Polling

Page

Q R e f e r e n c e Ta b l e B y t e #

Failure Error Data

Char Const Comp Corr Online Busy Active

Q R e f e r e n c e Ta b l e B y t e # 2 c o n t i n u e d

Char Const Low Format Waiting Ribbon Stock Online

Battery Error Fault Dispense Label

Q R e f e r e n c e Ta b l e B y t e # 3 c o n t i n u e d

Field Type Valid Options Description Identifier

B R e q u e s t

Status1,Status2,FMT-1,BCH-2

B R e s p o n s e

Packet Type

Status2

FMT-1/BCH-2

Error Number

Field Number

Parameter

Printed,total,FMT-1,BCH-2

Following syntax is the response for a Job 4 request

25,FMT-3,Bch-2

Number Meaning

14Status Polling

Status Polling

16Status Polling

A G N O S T I C S a N D Error S

User Diag

I n t i n g a Te s t L a b e l

Installed Options Description

Yo u R e c e i v e a n Error M e s s a g e

A d i n g a Te s t L a b e l

S e t t i n g P r i n t e r s

L l i n g Te c h n i c a l S u p p o r t

D i t i o n a l D i a g n o s t i c s I n f o r m a t i o n

T a Error s

A d i n g a n Error L a b e l

Error Description Code

Page

Page

Page

Page

Page

Page

Page

M m u n i c a t i o n F a i l u r e s

Page

Page

T a F o r m a t t i n g F a i l u r e s

Page

C h i n e Fault s

ENTER/PAUSE

Page

Space

Page

Printer Description Display

26Diagnostics and Errors

J u s t i n g t h e P r i n t Q u a l i t y

I N T E R O P T I M I Z AT I O N

Spec

Dark

D u c i n g I m a g i n g T i m e

4Printer Optimization

T h P a c k e t s

N e r a l F o r m a t T i p s a n d H i n t s

C r e a s i n g T h r o u g h p u t

T h F o r m a t s

T h B a r codes

You can group fields with similar parameters. For example

T h F i e l d s

M P L E SA

2Samples

M p l e U P C a F o r m a t P a c k e t

M p l e M a x i code P a c k e t s

Mode Description

4Samples

D e 0 O b s o l e t e S a m p l e

Samples A-5

D e 2 S a m p l e

6Samples

D e 3 S a m p l e

Samples A-7

M p l e D a t a M a t r i x P a c k e t s

U a r e D a t a M a t r i x P a c k e t

C t a n g u l a r D a t a M a t r i x P a c k e t

M p l e Q u i c k R e s p o n s e P a c k e t s

T e r i n g B a t c h D a t a f o r Q R code

Errorcor mask# datainput, char

HM,N0123456789012345 p

10Samples

Modeid code# #ofdiv parity, errorcor

Code P a c k e t

R u c t u r e d a p p e n d M o d e

Samples A-11

R u c t u r e d a p p e n d Q R code P a c k e t

Example 1,D0205E9,Q0A, p B006qrcode, p

12Samples

M p l e C o m p l i a n c e P a c k e t

Samples A-13

14Samples

Samples A-15

M p l e F o r m a t P a c k e t

16Samples

Sample Zero Batch Packet

M p l e D a t a E n t r y F o r m a t P a c k e t

18Samples

Fonts B-1

N T S

2Fonts

These samples were printed using the Internal Symbol set

Standard Font

Bold Font

Fonts B-3

These samples were printed using Code

CG Triumvirate Bold Font

CG Triumvirate Font 9pt

4Fonts

F TA F o n t 7 2 a n d F o n t 7 3 C h a r a c t e r s

T m a p F o n t I n f o r m a t i o n

Width Mag Standard Reduced Bold

N o s p a c e d F o n t M a g n i f i c a t i o n

I n g 2 0 3 D P

I n g 3 0 0 D P

Fonts B-7

8Fonts

Fonts B-9

Fonts

O p o r t i o n a l F o n t M a g n i f i c a t i o n

Tr i u m v i r a t e B o l d 9 p t 0 3 D P

I g h t M a g n i f i c a t i o n 2 0 3 D P

I g h t M a g n i f i c a t i o n 3 0 0 D P

Tr i u m v i r a t e B o l d 9 p t 0 0 D P

Fonts B-11

Tr i u m v i r a t e 6 p t 0 0 D P

I g h t M a g i n f i c a t i o n 2 0 3 D P

Tr i u m v i r a t e 7 p t 0 0 D P

Tr i u m v i r a t e 7 p t 0 3 D P

Fonts B-13

Tr i u m v i r a t e 9 p t 0 3 D P

Tr i u m v i r a t e 1 1 p t 0 3 D P

Tr i u m v i r a t e 9 p t 0 0 D P

Fonts B-15

Tr i u m v i r a t e 1 1 p t 0 0 D P

Fonts B-17

Tr i u m v i r a t e 1 5 p t 0 3 D P

Tr i u m v i r a t e 1 5 p t 0 0 D P

R m a t C o n s i d e r a t i o n s

A l a b l e / Tr u e Ty p e F o n t I n f o r m a t i o n

48pt Sample

W n l o a d i n g Tr u e Ty p e F o n t s 9 8 2 5 / 9 8 5

U b l e B y t e B i t m a p F o n t s

I n g a s i a n D o u b l e B y t e Tr u e Ty p e F o n t s

Character Mapping Code Batch Data

U b l e B y t e Tr u e Ty p e F o n t s

A r a c t e r M a p p i n g O v e r v i e w

Fonts B-23

C e n s i n g Yo u r F o n t s

1000

I n g F o n t N u m b e r s i n F o r m a t s

100

500

Font Number

Pages 437 or

P p o r t e d S y m b o l S e t s a n d code P a g e s

Internal

DOS Code

T e r i n g E x t e n d e d C h a r a c t e r s

I n g code 1 2 8 F u n c t i o n codes

T e r n a l S y m b o l S e t

Symbol Sets/Code Pages C-3

S I S y m b o l S e t L d C h a r a c t e r S e t

4Symbol Sets/Code Pages

Symbol Sets/Code Pages C-5

6Symbol Sets/Code Pages

Code P a g e 8 5 0 L a t i n Code P a g e 8 5 2 L a t i n

Symbol Sets/Code Pages C-7

8Symbol Sets/Code Pages

Symbol Sets/Code Pages C-9

10Symbol Sets/Code Pages

Symbol Sets/Code Pages C-11

12Symbol Sets/Code Pages

Symbol Sets/Code Pages C-13

Char Hex Decimal

14Symbol Sets/Code Pages

Symbol Sets/Code Pages C-15

16Symbol Sets/Code Pages

N a r y t o H e x C o n v e r s i o n C h a r t

Symbol Sets/Code Pages C-17

18Symbol Sets/Code Pages

Symbol Sets/Code Pages C-19

20Symbol Sets/Code Pages

F W h i t e D o t s

Symbol Sets/Code Pages C-21

T t o R u n L e n g t h E n c o d i n g C h a r t

B l a c k D o t s

22Symbol Sets/Code Pages

R M AT D E S I G N T O O L S

9403 printer does not support backfeed

L i n e C o n f i g u r a t i o n Wo r k s h e e t

Batch Control Continuation

T c h Wo r k s h e e t

E c k D i g i t Wo r k s h e e t

Supply Layout Inches

200 190 180 170 160 150 140 130 120 110 100

203

102 203 305 406 508 609 711 812 853

192 288 384 480 576 672 768 806

102 203 305 406 508 609 711 812

Supply Layout dpi 300

Format

Sample

I n t e r C o m p a r i s o n

Feature Printer

Printer Differences E-1

2Printer Differences

Feature Printer

4Printer Differences

Default configuration packet settings are

I n t e r C o n f i g u r a t i o n I n f o r m a t i o n

A t u s P o l l i n g I n f o r m a t i o n

Batch Packet

Monarch p

1,4,2 p Batch Header

N,1

6,1,3,1 p

Monospaced Fonts

Non-volatile RAM

Option

Index

D E

Packet control characters Security level of P D F417

Yrillic characters

Online configuration w orksheet D

Data type restrictions Fixed data

IM D

On a grid

List of options Sym bol selection 2

Restrictions w ith check digits

Increm enting/decrem enting field option

Description of 4

Odifying character w idth