μPD75P308

★6. RECOMMENDED SOLDERING CONDITIONS

It is recommended that μPD75P308 be soldered under the following conditions.

For details on the recommended soldering conditions, refer to Information Document "Semiconductor Devices Mounting Manual"

The soldering methods and conditions are not listed here, consult NEC.

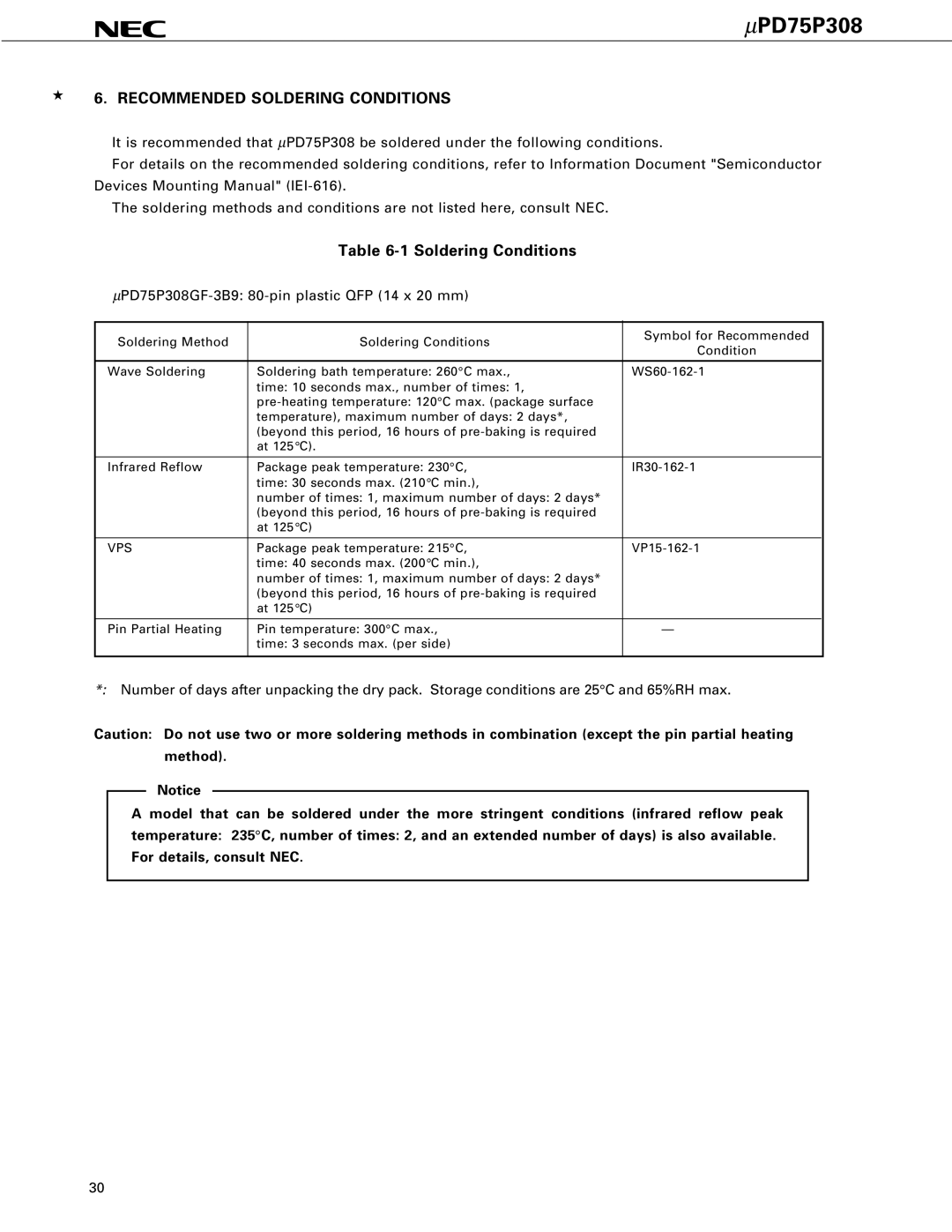

Table 6-1 Soldering Conditions

μPD75P308GF-3B9: 80-pin plastic QFP (14 x 20 mm)

Soldering Method | Soldering Conditions | Symbol for Recommended | |

Condition | |||

|

| ||

|

|

| |

Wave Soldering | Soldering bath temperature: 260°C max., | ||

| time: 10 seconds max., number of times: 1, |

| |

|

| ||

| temperature), maximum number of days: 2 days*, |

| |

| (beyond this period, 16 hours of |

| |

| at 125°C). |

| |

|

|

| |

Infrared Reflow | Package peak temperature: 230°C, | ||

| time: 30 seconds max. (210°C min.), |

| |

| number of times: 1, maximum number of days: 2 days* |

| |

| (beyond this period, 16 hours of |

| |

| at 125°C) |

| |

|

|

| |

VPS | Package peak temperature: 215°C, | ||

| time: 40 seconds max. (200°C min.), |

| |

| number of times: 1, maximum number of days: 2 days* |

| |

| (beyond this period, 16 hours of |

| |

| at 125°C) |

| |

|

|

| |

Pin Partial Heating | Pin temperature: 300°C max., | — | |

| time: 3 seconds max. (per side) |

| |

|

|

|

*: Number of days after unpacking the dry pack. Storage conditions are 25°C and 65%RH max.

Caution: Do not use two or more soldering methods in combination (except the pin partial heating method).

Notice

A model that can be soldered under the more stringent conditions (infrared reflow peak temperature: 235°C, number of times: 2, and an extended number of days) is also available.

For details, consult NEC.

30