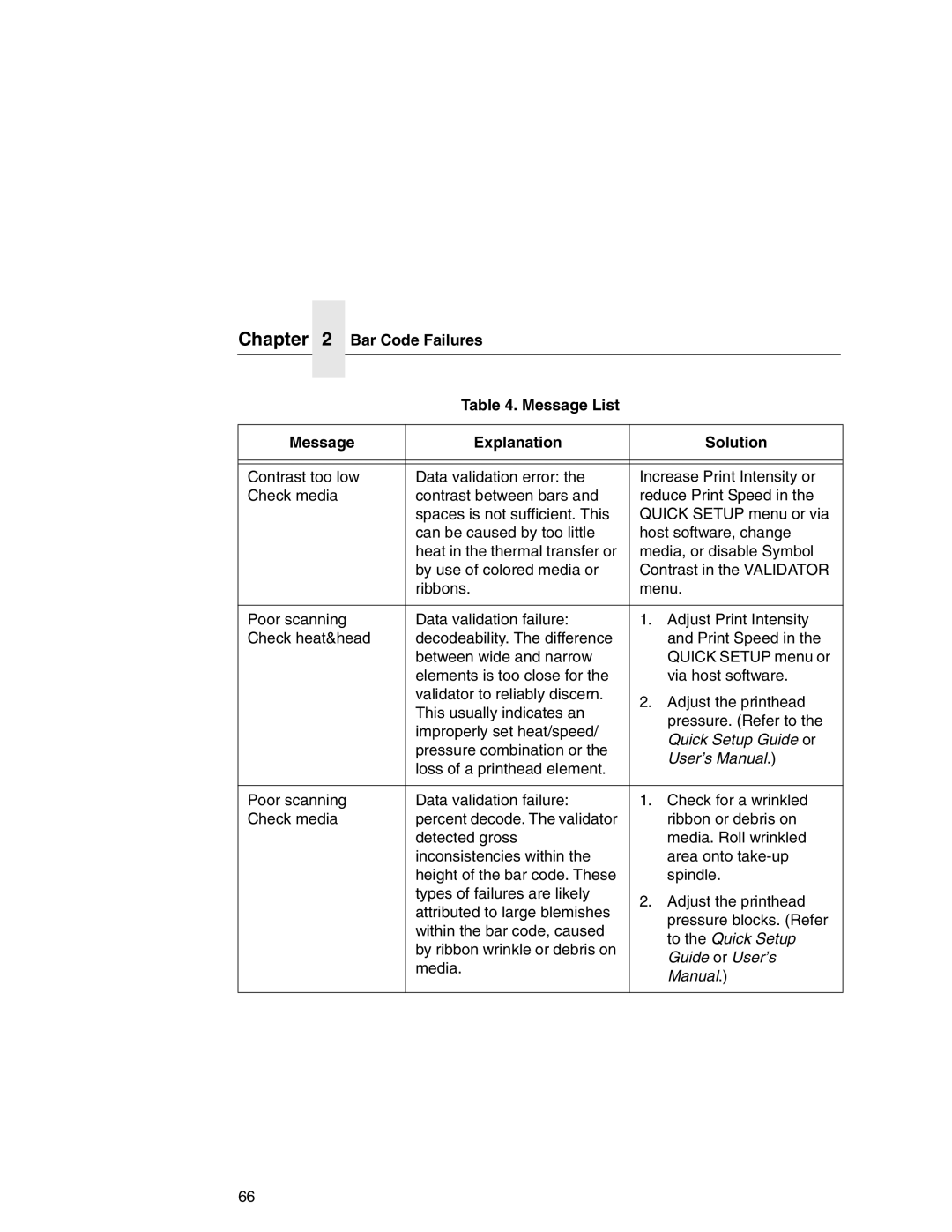

Chapter 2 Bar Code Failures

Table 4. Message List

Message | Explanation |

| Solution |

|

|

| |

|

|

| |

Contrast too low | Data validation error: the | Increase Print Intensity or | |

Check media | contrast between bars and | reduce Print Speed in the | |

| spaces is not sufficient. This | QUICK SETUP menu or via | |

| can be caused by too little | host software, change | |

| heat in the thermal transfer or | media, or disable Symbol | |

| by use of colored media or | Contrast in the VALIDATOR | |

| ribbons. | menu. | |

|

|

|

|

Poor scanning | Data validation failure: | 1. | Adjust Print Intensity |

Check heat&head | decodeability. The difference |

| and Print Speed in the |

| between wide and narrow |

| QUICK SETUP menu or |

| elements is too close for the |

| via host software. |

| validator to reliably discern. | 2. | Adjust the printhead |

| This usually indicates an | ||

|

| pressure. (Refer to the | |

| improperly set heat/speed/ |

| |

|

| Quick Setup Guide or | |

| pressure combination or the |

| |

|

| User’s Manual.) | |

| loss of a printhead element. |

| |

|

|

| |

|

|

| |

Poor scanning | Data validation failure: | 1. Check for a wrinkled | |

Check media | percent decode. The validator |

| ribbon or debris on |

| detected gross |

| media. Roll wrinkled |

| inconsistencies within the |

| area onto |

| height of the bar code. These |

| spindle. |

| types of failures are likely | 2. | Adjust the printhead |

| attributed to large blemishes | ||

|

| pressure blocks. (Refer | |

| within the bar code, caused |

| |

|

| to the Quick Setup | |

| by ribbon wrinkle or debris on |

| |

|

| Guide or User’s | |

| media. |

| |

|

| Manual.) | |

|

|

| |

|

|

|

|

66