Industry Sector, IA&DT

3.2Plant description

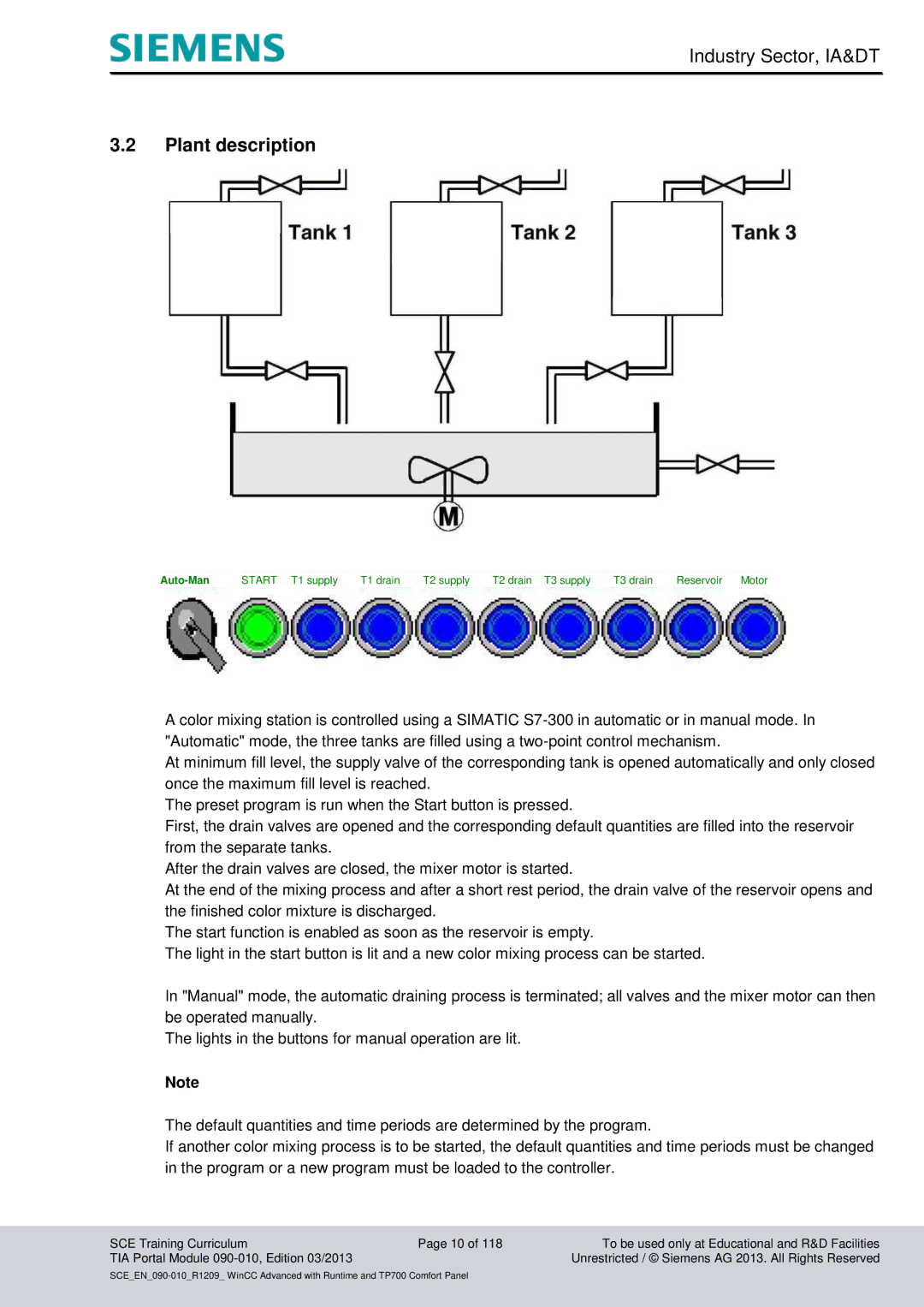

START T1 supply | T1 drain | T2 supply | T2 drain T3 supply | T3 drain | Reservoir Motor |

A color mixing station is controlled using a SIMATIC

At minimum fill level, the supply valve of the corresponding tank is opened automatically and only closed once the maximum fill level is reached.

The preset program is run when the Start button is pressed.

First, the drain valves are opened and the corresponding default quantities are filled into the reservoir from the separate tanks.

After the drain valves are closed, the mixer motor is started.

At the end of the mixing process and after a short rest period, the drain valve of the reservoir opens and the finished color mixture is discharged.

The start function is enabled as soon as the reservoir is empty.

The light in the start button is lit and a new color mixing process can be started.

In "Manual" mode, the automatic draining process is terminated; all valves and the mixer motor can then be operated manually.

The lights in the buttons for manual operation are lit.

Note

The default quantities and time periods are determined by the program.

If another color mixing process is to be started, the default quantities and time periods must be changed in the program or a new program must be loaded to the controller.

SCE Training Curriculum | Page 10 of 118 | To be used only at Educational and R&D Facilities |

TIA Portal Module |

| Unrestricted / © Siemens AG 2013. All Rights Reserved |