For Machines Mfg. Since 3/11 | M A I N T E N A N C E |

Lubrication

The following recommended lubrication schedules are based on

Failure to follow reasonable lubrication practices as instructed in this manual could lead to premature failure of lathe components and will void the warranty.

Headstock

Oil Type .. Mobil DTE Light or ISO 32 Equivalent

Oil Amount | 8 Quarts |

Check/Add Frequency | Daily |

Change Frequency | Every 6 Months |

The headstock gearing is lubricated by an oil bath that distributes the lubricant with the motion of the gears, much like an automotive manual transmission.

Checking Oil Level

The headstock has the proper amount of oil when the sight glass shown in Figure 106 is halfway full.

Headstock

Oil Sight

Glass

Figure 106. Location of headstock oil sight glass.

Adding Oil

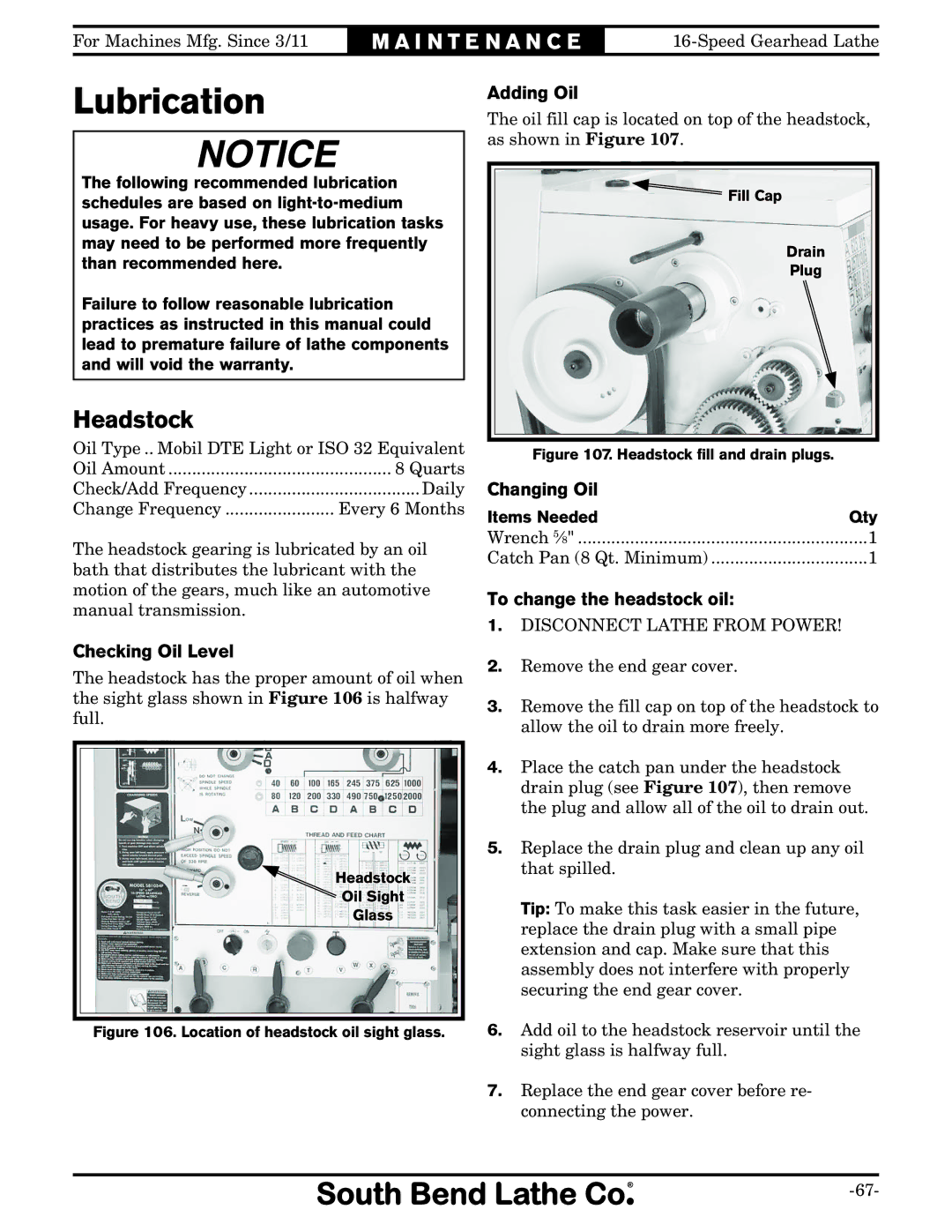

The oil fill cap is located on top of the headstock, as shown in Figure 107.

Fill![]()

![]() Cap

Cap

Drain

Plug

Figure 107. Headstock fill and drain plugs. |

|

Changing Oil |

|

Items Needed | Qty |

Wrench 5⁄8" | 1 |

Catch Pan (8 Qt. Minimum) | 1 |

To change the headstock oil:

1.DISCONNECT LATHE FROM POWER!

2.Remove the end gear cover.

3.Remove the fill cap on top of the headstock to allow the oil to drain more freely.

4.Place the catch pan under the headstock drain plug (see Figure 107), then remove the plug and allow all of the oil to drain out.

5.Replace the drain plug and clean up any oil that spilled.

Tip: To make this task easier in the future, replace the drain plug with a small pipe extension and cap. Make sure that this assembly does not interfere with properly securing the end gear cover.

6.Add oil to the headstock reservoir until the sight glass is halfway full.

7.Replace the end gear cover before re- connecting the power.