For Machines Mfg. Since 3/11 | O P E R A T I O N |

Removing Tooling

1.Use a shop rag to hold the tool.

2.Rotate the tailstock handwheel counterclockwise until the tool is forced out of the quill.

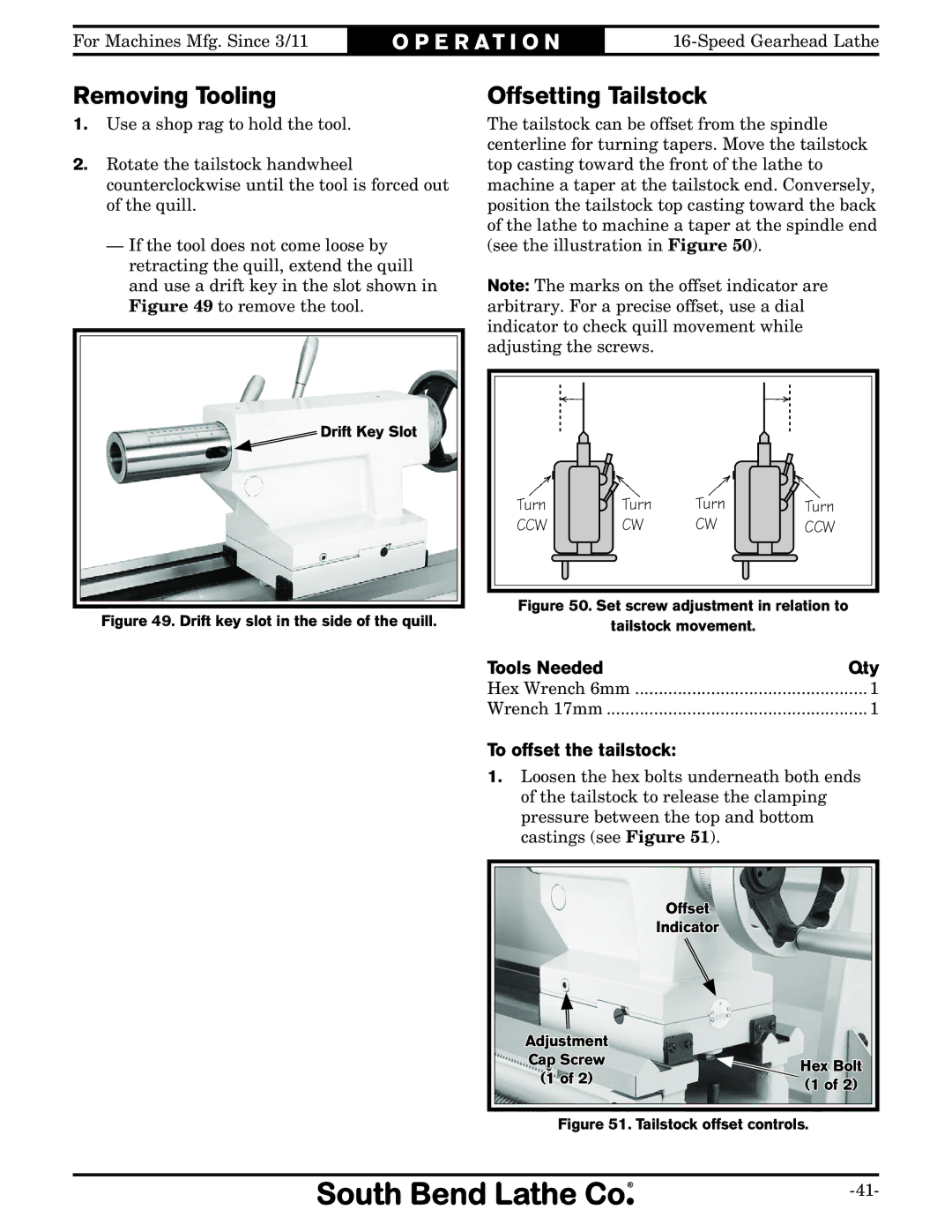

—If the tool does not come loose by retracting the quill, extend the quill and use a drift key in the slot shown in Figure 49 to remove the tool.

![]() Drift Key Slot

Drift Key Slot

Figure 49. Drift key slot in the side of the quill.

Offsetting Tailstock

The tailstock can be offset from the spindle centerline for turning tapers. Move the tailstock top casting toward the front of the lathe to machine a taper at the tailstock end. Conversely, position the tailstock top casting toward the back of the lathe to machine a taper at the spindle end (see the illustration in Figure 50).

Note: The marks on the offset indicator are arbitrary. For a precise offset, use a dial indicator to check quill movement while adjusting the screws.

Turn | Turn | Turn | Turn |

CCW | CW | CW | CCW |

Figure 50. Set screw adjustment in relation to

tailstock movement.

Tools Needed | Qty |

Hex Wrench 6mm | ................................................. 1 |

Wrench 17mm | 1 |

To offset the tailstock:

1.Loosen the hex bolts underneath both ends of the tailstock to release the clamping pressure between the top and bottom castings (see Figure 51).

Offset

Indicator

Adjustment |

| |

Cap Screw | Hex Bolt | |

(1 of 2) | ||

(1 of 2) | ||

|