S E R V I C E | For Machines Mfg. Since 3/11 |

9.Locate the brake switch on the right side of the brake pedal (see Figure 137).

Pedal

Cam

Brake

Switch

Figure 137. Brake switch and pedal cam.

10.Push the pedal lever down to verify that the cam lobe pushes the brake switch plunger in. When pushed in, the switch should click.

—If the switch does not click, loosen the switch mounting screws, push the brake pedal all the way down, then move the switch closer to the cam lobe until it clicks. Secure the switch in place at this location.

Note: When the brake pedal is released, there should be an approximate 3mm gap between the switch plunger and the cam lobe.

Leadscrew Shear Pin Replacement

The leadscrew is secured to a connecting collar that is part of the headstock drivetrain with the use of a

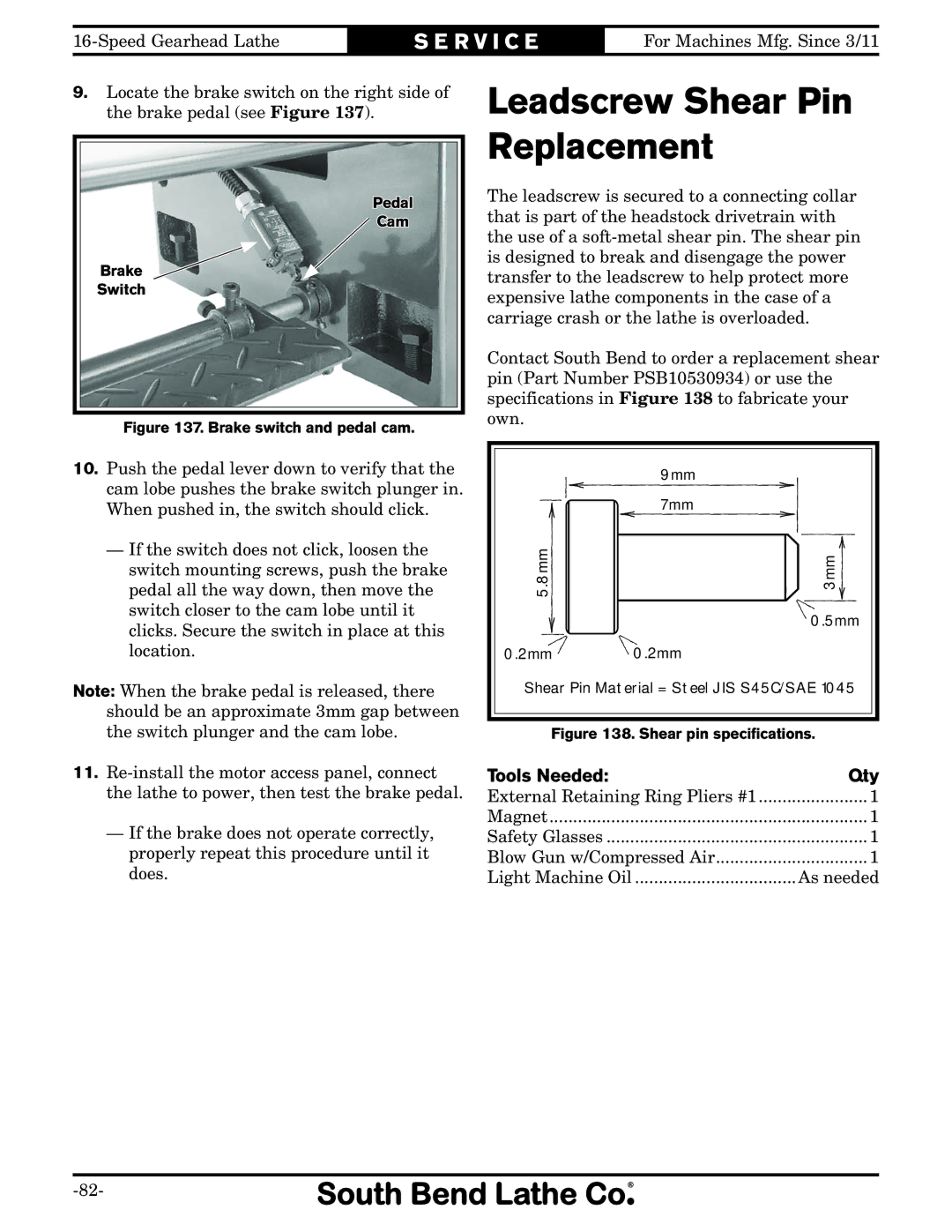

Contact South Bend to order a replacement shear pin (Part Number PSB10530934) or use the specifications in Figure 138 to fabricate your own.

| 9mm |

| 7mm |

5.8mm | 3mm |

| 0.5mm |

0.2mm | 0.2mm |

Shear Pin Material = Steel JIS S45C/SAE 1045 | |

Figure 138. Shear pin specifications.

11.

—If the brake does not operate correctly, properly repeat this procedure until it does.

Tools Needed: | Qty |

External Retaining Ring Pliers #1 | ....................... 1 |

Magnet | 1 |

Safety Glasses | 1 |

Blow Gun w/Compressed Air | 1 |

Light Machine Oil | As needed |