For Machines Mfg. Since 3/11 | P R E P A R A T I O N |

To level the machine, use a precision level to make sure the bedways are level from

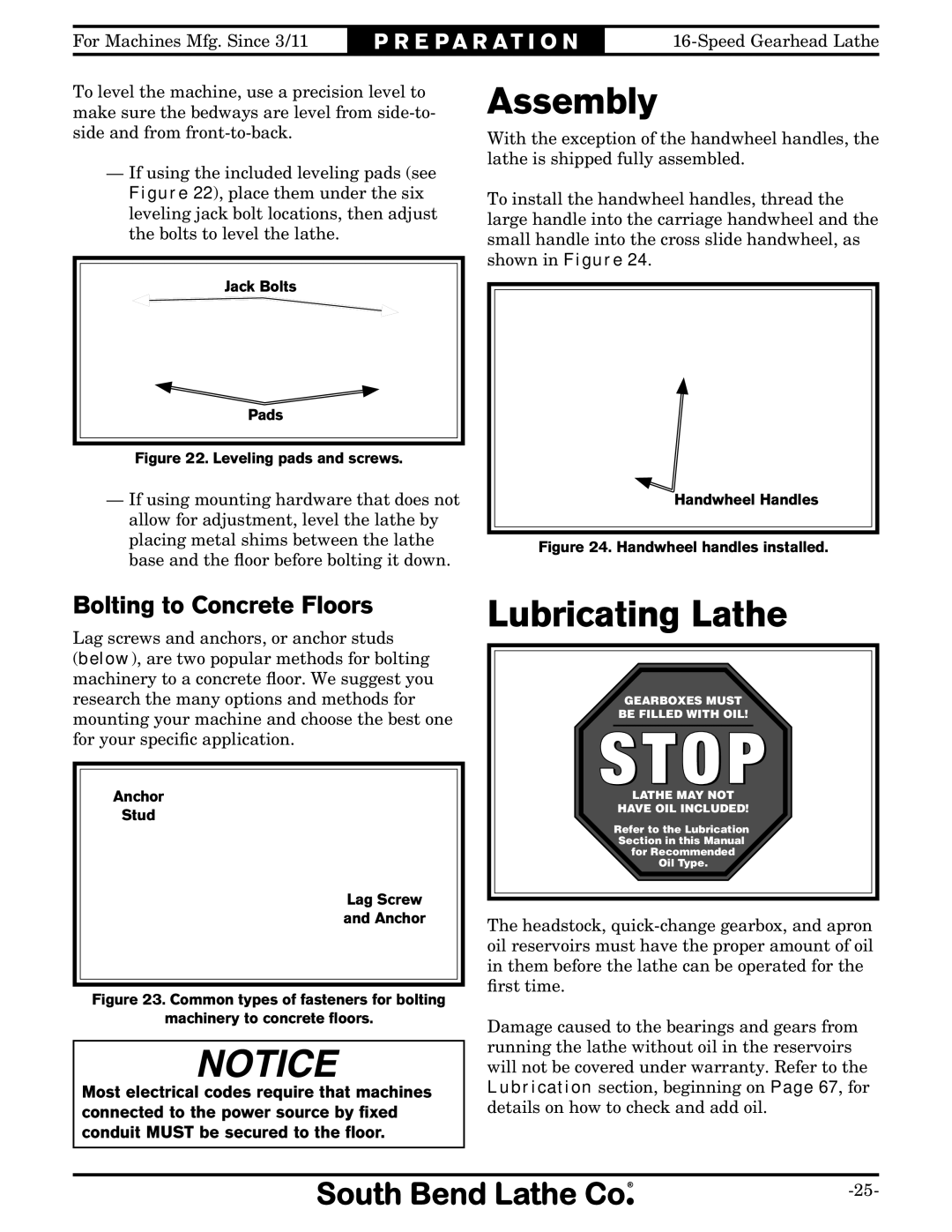

—If using the included leveling pads (see Figure 22), place them under the six leveling jack bolt locations, then adjust the bolts to level the lathe.

Jack Bolts

Pads

Figure 22. Leveling pads and screws.

—If using mounting hardware that does not allow for adjustment, level the lathe by placing metal shims between the lathe base and the floor before bolting it down.

Assembly

With the exception of the handwheel handles, the lathe is shipped fully assembled.

To install the handwheel handles, thread the large handle into the carriage handwheel and the small handle into the cross slide handwheel, as shown in Figure 24.

H![]()

![]() andwheel H

andwheel H![]()

![]() andles

andles

Figure 24. Handwheel handles installed.

Bolting to Concrete Floors

Lag screws and anchors, or anchor studs

(below), are two popular methods for bolting machinery to a concrete floor. We suggest you research the many options and methods for mounting your machine and choose the best one for your specific application.

Anchor

Stud

L![]()

![]() ag Screw

ag Screw

and Anchor

Figure 23. Common types of fasteners for bolting

machinery to concrete floors.

Most electrical codes require that machines connected to the power source by fixed conduit MUST be secured to the floor.

Lubricating Lathe

GEARBOXES MUST

BE FILLED WITH OIL!

LATHE MAY NOT

HAVE OIL INCLUDED!

Refer to the Lubrication Section in this Manual for Recommended

Oil Type.

The headstock,

Damage caused to the bearings and gears from running the lathe without oil in the reservoirs will not be covered under warranty. Refer to the Lubrication section, beginning on Page 67, for details on how to check and add oil.