For Machines Mfg. Since 3/11 | S E R V I C E |

Feed Rod Clutch

Adjustment

The feed rod clutch helps protect the drivetrain from overload in the event of a crash, and it works with the adjustable apron stop system to disengage the feed rod from the apron. The feed clutch release point is adjusted at the factory. However, it can be

Keep in mind that correctly adjusting the feed rod clutch for your operation is a matter of trial-

Setting the feed clutch for too high of a load defeats its purpose and could lead to lathe damage in the event of a crash.

Tools Needed: | Qty |

Hex Wrench 2.5mm | .............................................. 1 |

Hex Wrench 3mm | 1 |

To adjust the clutch release point:

1.DISCONNECT LATHE FROM POWER!

2.Remove the clutch front and side covers (see Figure 130).

![]() Feed Rod Clutch

Feed Rod Clutch

Side Cover Removed

From Here

Clutch Front

Cover

Figure 130. Location of feed rod clutch (side cover

removed for photo clarity).

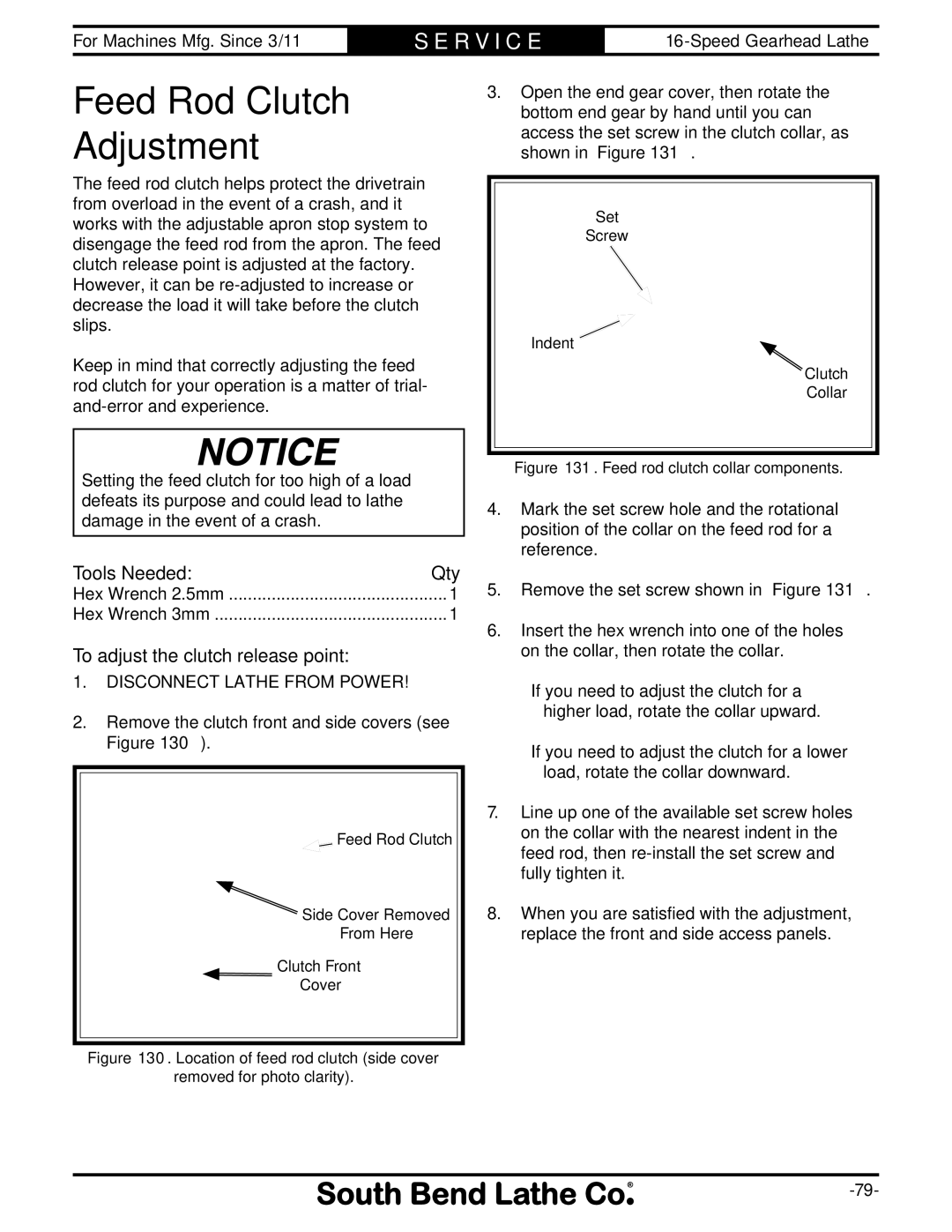

3.Open the end gear cover, then rotate the bottom end gear by hand until you can access the set screw in the clutch collar, as shown in Figure 131.

Set

Screw

Indent

Clutch

Collar

Figure 131. Feed rod clutch collar components.

4.Mark the set screw hole and the rotational position of the collar on the feed rod for a reference.

5.Remove the set screw shown in Figure 131.

6.Insert the hex wrench into one of the holes on the collar, then rotate the collar.

—If you need to adjust the clutch for a higher load, rotate the collar upward.

—If you need to adjust the clutch for a lower load, rotate the collar downward.

7.Line up one of the available set screw holes on the collar with the nearest indent in the feed rod, then

8.When you are satisfied with the adjustment, replace the front and side access panels.