SUF 199 & SUF 250 Intake Air Connection

SUF 100 199 and SUF 100 250 models are factory equipped with a unique Combustion Blower and intake air connection Tee fitting. The Tee is a 3" x 3" x 1/2" fitting. The intake air connection Tee fitting has a hose barb installed in the 1/2 inch branch to connect the Blocked Intake Air switch sensing tube, see Figure 15.

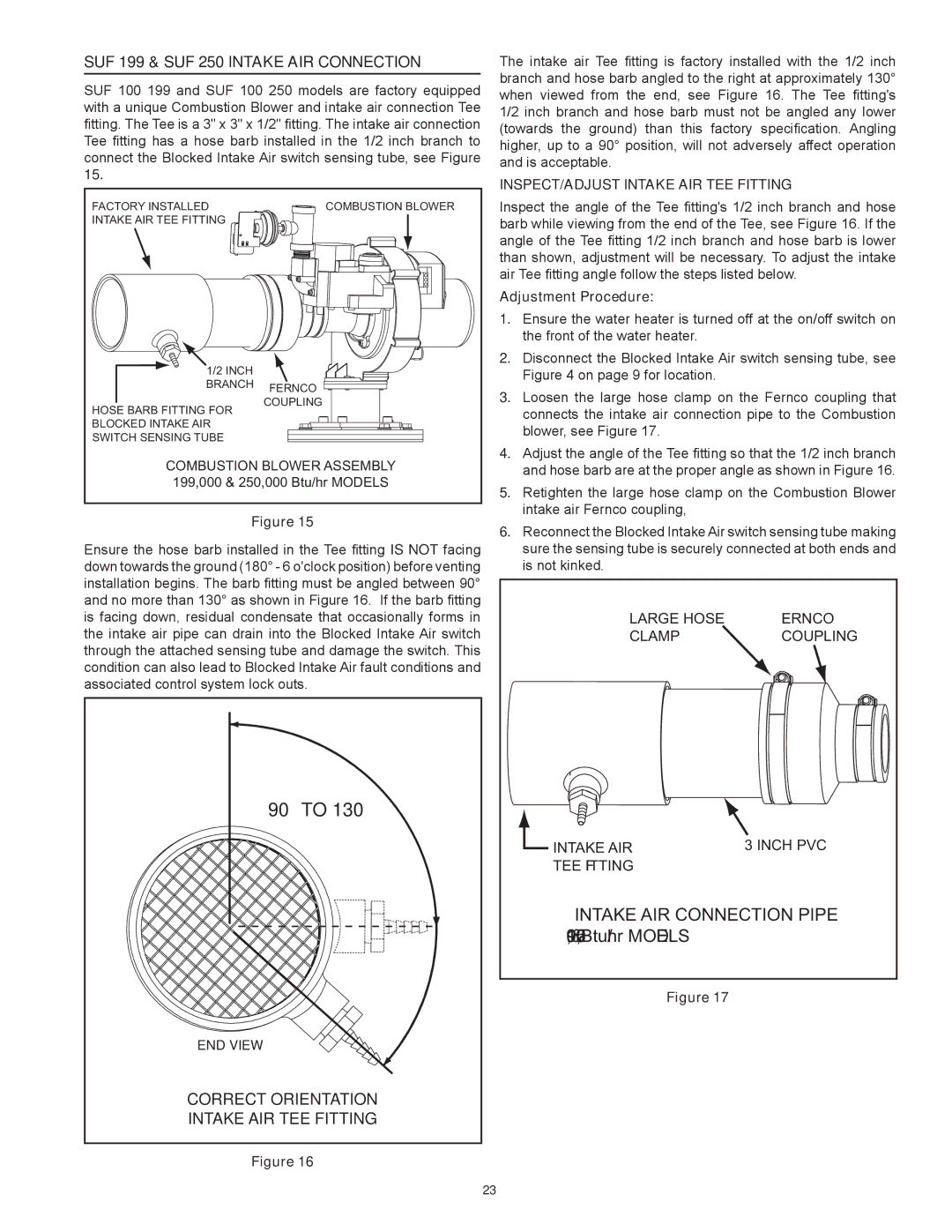

The intake air Tee fitting is factory installed with the 1/2 inch branch and hose barb angled to the right at approximately 130° when viewed from the end, see Figure 16. The Tee fitting's 1/2 inch branch and hose barb must not be angled any lower (towards the ground) than this factory specification. Angling higher, up to a 90° position, will not adversely affect operation and is acceptable.

Inspect/Adjust Intake Air Tee Fitting

FACTORY INSTALLED INTAKE AIR TEE FITTING

1/2 INCH BRANCH

HOSE BARB FITTING FOR BLOCKED INTAKE AIR SWITCH SENSING TUBE

COMBUSTION BLOWER

FERNCO

COUPLING

Inspect the angle of the Tee fitting's 1/2 inch branch and hose barb while viewing from the end of the Tee, see Figure 16. If the angle of the Tee fitting 1/2 inch branch and hose barb is lower than shown, adjustment will be necessary. To adjust the intake air Tee fitting angle follow the steps listed below.

Adjustment Procedure:

1. | Ensure the water heater is turned off at the on/off switch on |

| the front of the water heater. |

2. | Disconnect the Blocked Intake Air switch sensing tube, see |

| Figure 4 on page 9 for location. |

3. | Loosen the large hose clamp on the Fernco coupling that |

| connects the intake air connection pipe to the Combustion |

| blower, see Figure 17. |

4. | Adjust the angle of the Tee fitting so that the 1/2 inch branch |

COMBUSTION BLOWER ASSEMBLY 199,000 & 250,000 Btu/hr MODELS

Figure 15

Ensure the hose barb installed in the Tee fitting is not facing down towards the ground (180° - 6 o'clock position) before venting installation begins. The barb fitting must be angled between 90° and no more than 130° as shown in Figure 16. If the barb fitting is facing down, residual condensate that occasionally forms in the intake air pipe can drain into the Blocked Intake Air switch through the attached sensing tube and damage the switch. This condition can also lead to Blocked Intake Air fault conditions and associated control system lock outs.

90° TO 130° |

END VIEW |

CORRECT ORIENTATION |

INTAKE AIR TEE FITTING |

Figure 16

| and hose barb are at the proper angle as shown in Figure 16. |

5. | Retighten the large hose clamp on the Combustion Blower |

| intake air Fernco coupling, |

6. | Reconnect the Blocked Intake Air switch sensing tube making |

| sure the sensing tube is securely connected at both ends and |

| is not kinked. |

LARGE HOSE | FERNCO |

CLAMP | COUPLING |

INTAKE AIR | 3 INCH PVC |

TEE FITTING |

|

INTAKE AIR CONNECTION PIPE 199,000 & 250,000 Btu/hr MODELS

Figure 17

23