Model 200AU Nitrogen Oxides Analyzer

SAN DIEGO, CA TOLL-FREE FAX TEL Mail api-sales@teledyne.com

Safety Messages

Table of Contents

Optional Hardware and Software

Maintenance

Subsystem Troubleshooting and Adjustments

10-1

List of Figures

Vii

List of Tables

Viii

16 Activity Matrix for Data Quality

Intentionally Blank

HOW to USE this Manual

Intentionally Blank

Electrical and Pneumatic Connections

Getting Started

Unpacking

Page

Removal of Shipping Screws & Check for Correct Power

Rear Panel

Inlet and Exhaust Venting

Initial Operation

Step Number Action Comment

Zero/Span Calibration Procedure

Calibration Quality Check Procedure

Front Panel

Assembly Layout

Electric Test & Optic Test

Final Test and Calibration Values

Test Values Observed Units Nominal Range Reference Section

Factory Installed Options Option Installed

Measured Flows

Intentionally Blank

SPECIFICATIONS, Agency APPROVALS, Warranty

Specifications

EPA Equivalency Designation

Warranty

Warranty Policy

Terms and Conditions

M200AU NOX Analyzer

Principle of Operation

Block Diagram

Pneumatic Sensor Board

Operation Summary

Sensor Module, Reaction Cell, Detector

CPU Board

Computer Hardware and Software

4 V/F Board

Status LEDs

Front Panel

Keyboard

State Meaning

Power Switch

Front Panel Status LEDs

Ozone Generator

Power Supply Module

Pump, Valves, Pneumatic System

Ozone Generator Start-up Timing

Time Since Last Ozone Gen State Program Action Power-up

Molybdenum Converter Ozone Scrubber

Software Features

Index To Front Panel Menus

Sample Menu Tree

Setup Menu Tree

Sample Menu

Sample Menu

Conv

Setup Menu

Set-Up Menu

View

Setup Menu #2 Level Description Reference Section

Setup Menu #3 Level Description Reference Section

Range

Sample Mode

Test Functions

High Voltage Power Supply Hvps

Sample Flow

Ozone Flow

PMT Voltage

DC Power Supply Dcps

Reaction Cell Temperature

Box Temperature

PMT Temperature

2 CAL, CALS, CALZ, Calibration Functions

Sample Pressure

NOx, no Slope and Offset Values

Time

2.4 NO, NOx Cal Concentration

Zero

Span

Formula Values

Set-Up Mode

Configuration Information CFG

Automatic Calibration AutoCal

Data Acquisition System DAS

Data Channels

Page

Step Action Comment Press SETUP-DAS-EDIT

Range Menu

DAS Data Channel Editing

Single Range

Concentration Units

Auto Range

Independent Ranges

Password Enable

Calibrate, Setup Passwords

Password Usage

Recorder Offset

Diagnostic Mode

Time of Day Clock

Communications Menu

Variables Menu Vars

M200AU Operating Modes

Mode Description

Status Output

Output # Pin # Definition Condition

RS-232 Interface

Status Output Pin Assignments

Setting Up the RS-232 Interface

Setup from the Front Panel

10 RS-232 Port Setup Front Panel

Decimal Value Description

Security Feature

Protocol of Port Communication

11 RS-232 Switching From Terminal Mode to Computer Mode

Entering Commands in Terminal Mode

12 RS-232 Terminal Mode Editing Keys

Key Function

Command Summary

Compactverbose

13 RS-232 Command Summary

Commands Definition

14 RS-232 Command Summary

Terminal Mode Editing Keys Definition

Computer Mode Editing Keys Definition

Security Features Definition

15 RS-232 Interface Command Types

First Character Message Type

Name Message Description

Test Commands and Messages

16 RS-232 Test Messages

17 RS-232 Warning Messages

Command Description

Calibration Commands and Messages

18 RS-232 Calibration Commands

Action RS-232 Commands Comments

19 RS-232 Calibration Examples

Message Description

Diagnostic Commands and Messages

20 RS-232 Calibration Messages

DAS Commands and Message

21 RS-232 Diagnostic Command Summary

Conc

Internal Variables

List

CPU should respond with

Mode Description Reference Section

Optional Hardware and Software

Rack Mount Options

Zero/Span Valves

Autocal Setup Zero/Span Valves

Mode No Mode Name Action

Mode and Attribute Value Comment

Attribute No Attribute Name Action

Example of AutoCal Setup

SETUP-ACAL

4-20 mA, Current Loop Output

NOy Converter

Calibration & ZERO/SPAN Checks

Types of Zero/Span Check and Calibration

Section Type of Cal or Check Description

Calibration Setup

Manual Zero Calibration Procedure Zero Gas thru Sample Port

Enter Expected Span Gas Concentrations Procedure

Manual Span Calibration Procedure Span Gas thru Sample Port

Manual Zero Calibration Procedure Z/S Valves

Dynamic Zero/Span Calibration

Manual Span Calibration Procedure Z/S Valves

Automatic Zero/Span Check

Use of Zero/Span Valves with Remote Contact Closure

Enabling Dynamic Zero/Span

EPA Protocol Calibration

Calibration of Equipment

Z/S Valves Modes with Remote Contact Closure

Ext Zero CC Ext Span CC Operation

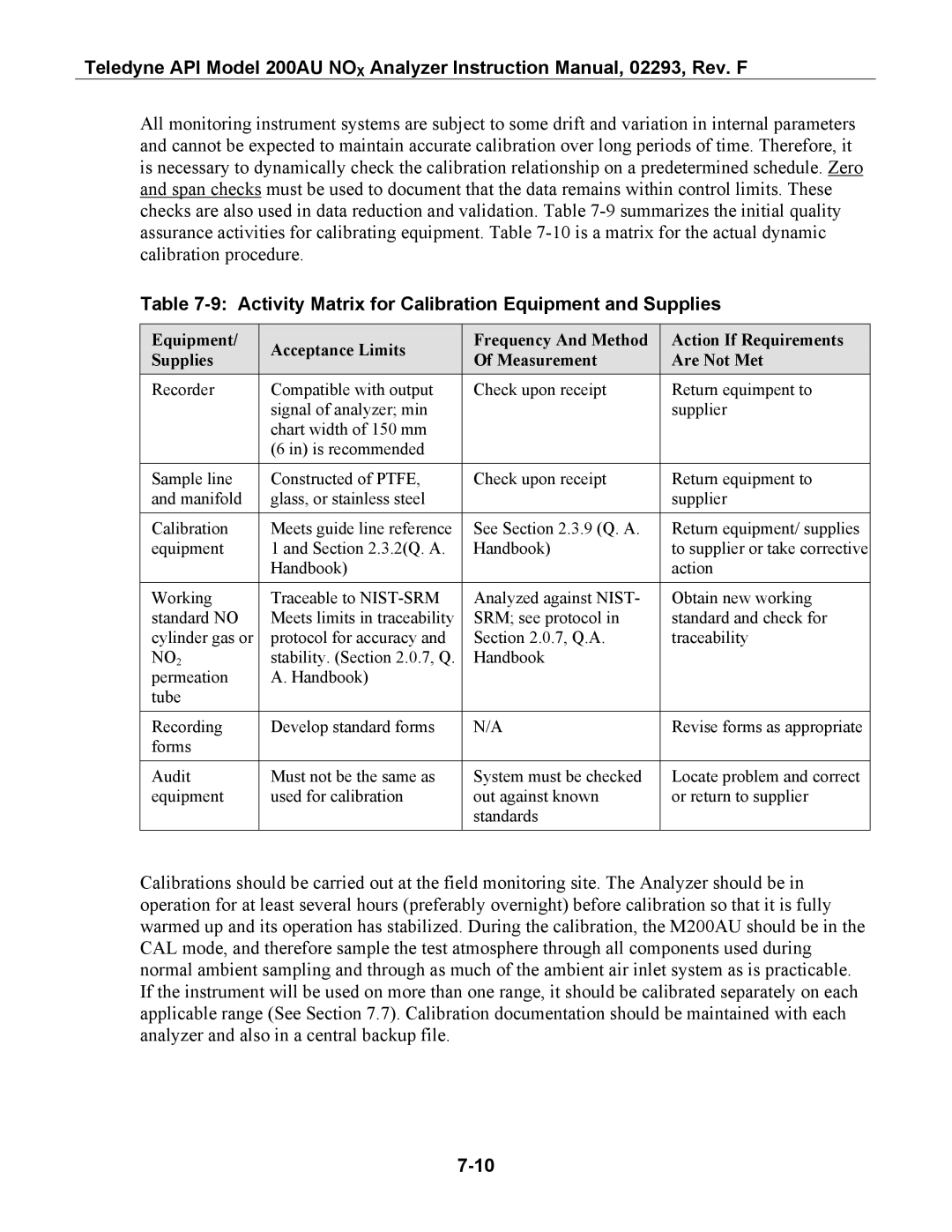

Activity Matrix for Calibration Equipment and Supplies

NO2

10 Activity Matrix for Calibration Procedure

Calibration Gas and Zero Air Sources

Production of Zero Air

GPT

Gas Phase Titration GPT System

Gas Phase Titration GPT

Data Recording Device

Selection of no span gas standards

GPT Calibrator Check Procedure

FT = analyzer flow demand cm3/min x 110/100 Equation

No OUT

Example Calculation

FT = 1000 cm3/min 110/100 = 1100 cm3/min

Dynamic Multipoint Calibration Procedure

180 cm

Page

Diagram of GPT Calibration System

5.2 NO/NOx Calibration Procedure

Zero Calibration Procedure

11 Zero Calibration Procedure

12 Expected Span Gas Concentration Procedure

13 Span Calibration Procedure

GPT NO2 Calibration Procedure

= no Orig No REM No * no

Moly Converter Efficiency

Automatic Moly Converter Efficiency Compensation

14 Automatic Calculation of Converter Efficiency

CAL-CONC

CONV-NO2

CAL-CONC MOLY-SET

Other Quality Assurance Procedures

Calibration Frequency

15 Definition of Level 1 and Level 2 Zero and Span Checks

Level 1 Zero and Span Calibration

Summary of Quality Assurance Checks

Characteristic Acceptance Limits Frequency And Method

16 Activity Matrix for Data Quality

Measurement Are Not Met

Test

Zero/Span Check Procedures

Zero and Span Checks

Precision Check

Precision Check Procedure

Recommended Standards for Establishing Traceability

Type Size, at STP Nominal Concentration

Certification Procedures of Working Standards

Permeation Tubes

Calibration of Independent Ranges or Autoranging

Zero Calibration with AutoRange or Independent Range

No Working Standard Traced to Nist no Standard

Other Methods of Establishing Traceability

Calibration Quality

Span Calibration with AutoRange or Independent Range

18 Calibration Quality Check

References

Intentionally Blank

Maintenance

Maintenance Schedule

Preventative Maintenance Schedule

Maintenance Interval Reference Section

Preventative Maintenance Calendar

Replacing the Sample Particulate Filter

Replacing the Particulate Filter

Sample Pump Maintenance

Sample Pump Assembly

Cleaning the Reaction Cell

Reaction Cell Assembly

Replacing the Molybdenum Converter

Molybdenum Converter Assembly

Pneumatic Line Inspection

Pneumatic Diagram Standard Configuration

Pneumatic Diagram with Zero/Span Valve Option

Pneumatic Diagram with External Converter Option

Leak Check Procedure

Pressure must be less than 15 psi

Light Leak Check Procedure

Prom Replacement Procedure

Page

Intentionally Blank

TROUBLESHOOTING, Adjustments

Page

Operation Verification-M200AU Diagnostic Techniques

Fault Diagnosis with Test Variables

Test Functions

Test Function Factory Set-Up Comment

Ozone FL

Prereact

Moly Temp

Fault Diagnosis with Warning Messages

Front Panel Warning Messages

Not Installed

Pract WRN XXX.X MV

Fault Diagnosis using Diagnostic Mode

Summary of Diagnostic Modes

Diag Mode Description

Signal I/O Diagnostic Diagnostic Mode Signal I/O

Signal Control Description

Stflowalarm YES

Sttempalarm YES

Stpowerok YES

Convheater YES

Pmtsignal

Stsystemok YES

Sthighrange YES

Samplepres

Electric Test

Optic Test

Ozone Gen Power

Analog Out Step Test

DAC Calibration

3.7 RS-232 Port Test

Tpcenable

4 M200AU Internal Variables

Name Units Default Value Description Range

Model 200AU Variables

Test Channel Minimum Maximum Description

Test Channel Analog Output

Test Channel Readings

Block Temp

IZS Temp

Conv Temp

Chassis

Factory Calibration Procedure

Page

Span Calibration Voltage

Performance Problems

AC Power Check

Flow Check

No Response to Sample Gas

Negative Output

Excessive Noise

Unstable Span

Unstable Zero

Inability to Span

Inability to Zero

Non-Linear Response

Subsystem Troubleshooting and Adjustments

Slow Response

Analog Output Doesnt Agree with Display Concentration

Computer, Display, Keyboard

Front Panel Display

Single Board Computer

CPU Board Jumper Settings

Front Panel Keyboard

Physical Wiring

2 RS-232 Communications

2.1 RS-232 Connection

RS-232 Protocol Baud rate, Data bits, Parity

2.2 RS-232 Diagnostic Procedures

RS-232 PIN Assignments

Voltage/Frequency V/F Board

Page

3.1 ADC/DAC Calibration Procedure

Motherboard Jumper Settings

Board Switch Settings

Motherboard Jumpers

V/F Board Switch Settings

Output or non-isolated current loop

Output or isolated current loop

Output

Page

V/F Board Settings

Changing Output Voltage Ranges

Temperature Amplifier Section

Status/Temp Board

Display Brownout

Thermistor Temperature Amplifier Adjustments

Molybdenum Converter Thermocouple Amplifier Adjustments

Status Output Lines, External Contact Closures

4.4 4-20 mA Current Output

Power Supply Module Subassemblies

Module Description

Power Supply Module Layout

Electrical Block Diagram

Function Description

PSM Diagnostic Procedures

10 Power Supply Module LED Operation

Ozone Generator

11 Ozone Generator Control Conditions

PermaPure Drier

Ozone Generator Subsystem

Flow/Pressure Sensor

Page

Flow/Pressure Sensor

NOx Sensor Module

10 NOx Sensor Module

NOx Sensor Module

8.1 PMT

Reaction Cell Temp

Preamp Board

11 PMT Cooler Subsystem

PMT Cooler

High Voltage P.S

12 High Voltage Power Supply

9 Z/S Valves

Leak Check

Sample Pump Diagnostic Procedures

Pneumatic System

Intentionally Blank

10-1

10 M200AU Spare Parts List

Teledyne API M200AU Spare Parts List

10-2

023180000 M200AU Expendables Kit Includes Qty

Teledyne API Model 200AU Expendable Kit

10-3

10-4

Name

Appendix a Electrical Schematics

Table A-1 Electrical Schematics

Table A-1 Electrical Schematics