1 TROUBLESHOOTING FOR THE HARDWARE

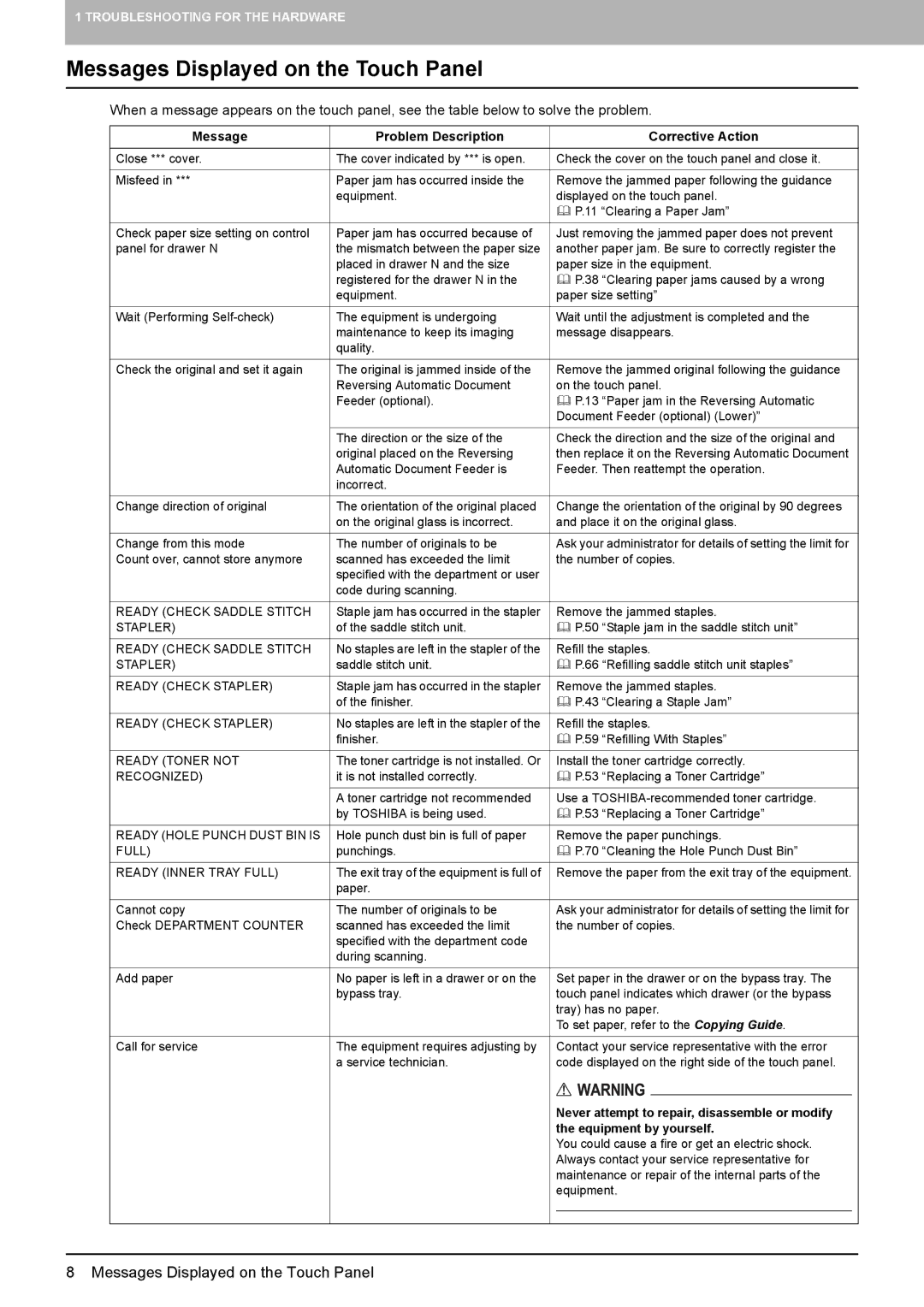

Messages Displayed on the Touch Panel

When a message appears on the touch panel, see the table below to solve the problem.

| Message | Problem Description |

|

| Corrective Action |

| |

|

|

|

|

| |||

| Close *** cover. | The cover indicated by *** is open. | Check the cover on the touch panel and close it. |

| |||

|

|

|

|

|

| ||

| Misfeed in *** | Paper jam has occurred inside the |

| Remove the jammed paper following the guidance |

| ||

|

| equipment. |

| displayed on the touch panel. |

| ||

|

|

|

| P.11 “Clearing a Paper Jam” |

| ||

|

|

|

|

|

| ||

| Check paper size setting on control | Paper jam has occurred because of |

| Just removing the jammed paper does not prevent |

| ||

| panel for drawer N | the mismatch between the paper size |

| another paper jam. Be sure to correctly register the |

| ||

|

| placed in drawer N and the size |

| paper size in the equipment. |

| ||

|

| registered for the drawer N in the |

| P.38 “Clearing paper jams caused by a wrong |

| ||

|

| equipment. |

| paper size setting” |

| ||

|

|

|

|

|

| ||

| Wait (Performing | The equipment is undergoing |

| Wait until the adjustment is completed and the |

| ||

|

| maintenance to keep its imaging |

| message disappears. |

| ||

|

| quality. |

|

|

|

|

|

|

|

|

|

|

| ||

| Check the original and set it again | The original is jammed inside of the |

| Remove the jammed original following the guidance |

| ||

|

| Reversing Automatic Document |

| on the touch panel. |

| ||

|

| Feeder (optional). |

| P.13 “Paper jam in the Reversing Automatic |

| ||

|

|

|

| Document Feeder (optional) (Lower)” |

| ||

|

|

|

|

|

| ||

|

| The direction or the size of the |

| Check the direction and the size of the original and |

| ||

|

| original placed on the Reversing |

| then replace it on the Reversing Automatic Document |

| ||

|

| Automatic Document Feeder is |

| Feeder. Then reattempt the operation. |

| ||

|

| incorrect. |

|

|

|

|

|

|

|

|

|

|

| ||

| Change direction of original | The orientation of the original placed |

| Change the orientation of the original by 90 degrees |

| ||

|

| on the original glass is incorrect. |

| and place it on the original glass. |

| ||

|

|

|

|

|

| ||

| Change from this mode | The number of originals to be |

| Ask your administrator for details of setting the limit for |

| ||

| Count over, cannot store anymore | scanned has exceeded the limit |

| the number of copies. |

| ||

|

| specified with the department or user |

|

|

|

|

|

|

| code during scanning. |

|

|

|

|

|

|

|

|

|

|

| ||

| READY (CHECK SADDLE STITCH | Staple jam has occurred in the stapler |

| Remove the jammed staples. |

| ||

| STAPLER) | of the saddle stitch unit. |

| P.50 “Staple jam in the saddle stitch unit” |

| ||

|

|

|

|

|

| ||

| READY (CHECK SADDLE STITCH | No staples are left in the stapler of the |

| Refill the staples. |

| ||

| STAPLER) | saddle stitch unit. |

| P.66 “Refilling saddle stitch unit staples” |

| ||

|

|

|

|

|

| ||

| READY (CHECK STAPLER) | Staple jam has occurred in the stapler |

| Remove the jammed staples. |

| ||

|

| of the finisher. |

| P.43 “Clearing a Staple Jam” |

| ||

|

|

|

|

|

| ||

| READY (CHECK STAPLER) | No staples are left in the stapler of the |

| Refill the staples. |

| ||

|

| finisher. |

| P.59 “Refilling With Staples” |

| ||

|

|

|

|

|

| ||

| READY (TONER NOT | The toner cartridge is not installed. Or |

| Install the toner cartridge correctly. |

| ||

| RECOGNIZED) | it is not installed correctly. |

| P.53 “Replacing a Toner Cartridge” |

| ||

|

|

|

|

|

| ||

|

| A toner cartridge not recommended |

| Use a |

| ||

|

| by TOSHIBA is being used. |

| P.53 “Replacing a Toner Cartridge” |

| ||

|

|

|

|

|

| ||

| READY (HOLE PUNCH DUST BIN IS | Hole punch dust bin is full of paper |

| Remove the paper punchings. |

| ||

| FULL) | punchings. |

| P.70 “Cleaning the Hole Punch Dust Bin” |

| ||

|

|

|

|

|

| ||

| READY (INNER TRAY FULL) | The exit tray of the equipment is full of |

| Remove the paper from the exit tray of the equipment. |

| ||

|

| paper. |

|

|

|

|

|

|

|

|

|

|

| ||

| Cannot copy | The number of originals to be |

| Ask your administrator for details of setting the limit for |

| ||

| Check DEPARTMENT COUNTER | scanned has exceeded the limit |

| the number of copies. |

| ||

|

| specified with the department code |

|

|

|

|

|

|

| during scanning. |

|

|

|

|

|

|

|

|

|

|

| ||

| Add paper | No paper is left in a drawer or on the |

| Set paper in the drawer or on the bypass tray. The |

| ||

|

| bypass tray. |

| touch panel indicates which drawer (or the bypass |

| ||

|

|

|

| tray) has no paper. |

| ||

|

|

|

| To set paper, refer to the Copying Guide. |

| ||

|

|

|

|

|

| ||

| Call for service | The equipment requires adjusting by |

| Contact your service representative with the error |

| ||

|

| a service technician. |

| code displayed on the right side of the touch panel. |

| ||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

| Never attempt to repair, disassemble or modify |

| ||

|

|

|

| the equipment by yourself. |

| ||

|

|

|

| You could cause a fire or get an electric shock. |

| ||

|

|

|

| Always contact your service representative for |

| ||

|

|

|

| maintenance or repair of the internal parts of the |

| ||

|

|

|

| equipment. |

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|