9 IMPROVING SYSTEM EFFICIENCY

Air flow direction adjustment

1.To improve the effects of cooling and heating, use the outlet louver appropriately for cooling and heating operations. When in cooling operation the most efficient louver position will be horizontal and when in heating operation the optimum louver position is downwards.

Increasing heating effect

1.One method increase the warming effect is to fit an additional means of

2.However if the warming effect of the air conditioner is not good owing to the installation position or the structure of the room, then reset the room temperature regulator as follows to raise the temperature of the room. Adjust position 1 and 2 on DIP switch SW03 located on the indoor P.C. board, according to the table below :

Dip switch SW03 | Position 1 | : ON | Position 1 : OFF | Position 1 : OFF |

|

|

|

| |

position 1 & 2 | Position 2 | : OFF | Position 2 : ON | Position 2 : OFF |

| ||||

|

|

|

| |

Temperature increased | Factory | +2°C | +4°C | |

|

|

|

|

|

Options

Test operation

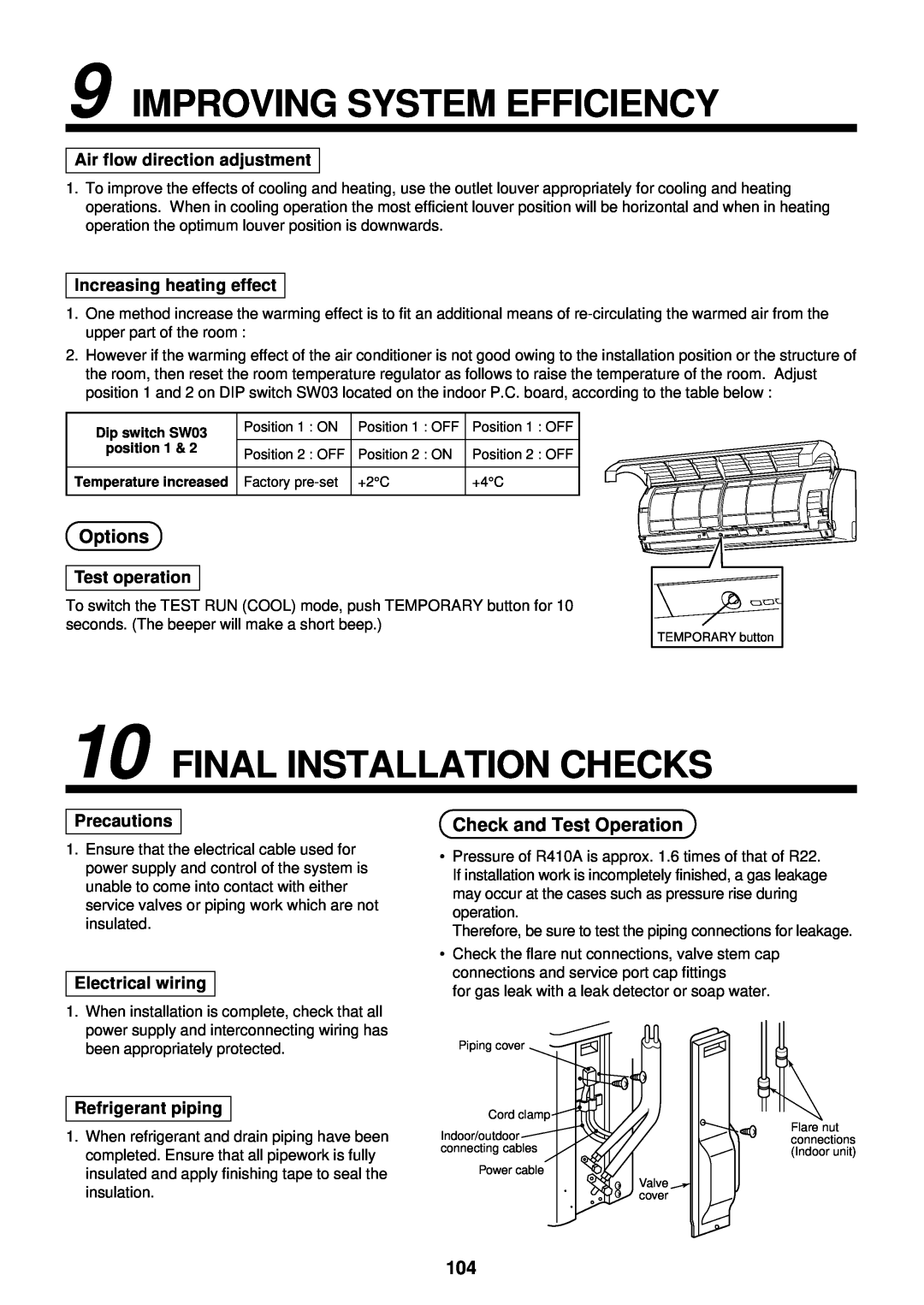

To switch the TEST RUN (COOL) mode, push TEMPORARY button for 10 seconds. (The beeper will make a short beep.)

TEMPORARY button

10 FINAL INSTALLATION CHECKS

Precautions

Check and Test Operation

1.Ensure that the electrical cable used for power supply and control of the system is unable to come into contact with either service valves or piping work which are not insulated.

Electrical wiring

1.When installation is complete, check that all power supply and interconnecting wiring has been appropriately protected.

Refrigerant piping

1.When refrigerant and drain piping have been completed. Ensure that all pipework is fully insulated and apply finishing tape to seal the insulation.

•Pressure of R410A is approx. 1.6 times of that of R22. If installation work is incompletely finished, a gas leakage may occur at the cases such as pressure rise during operation.

Therefore, be sure to test the piping connections for leakage.

•Check the flare nut connections, valve stem cap connections and service port cap fittings

for gas leak with a leak detector or soap water.

Piping cover

Cord clamp

Indoor/outdoor | Flare nut | |

connections | ||

connecting cables | ||

(Indoor unit) | ||

| ||

Power cable | Valve | |

| ||

| cover |

104